Garbage sorting and conveying device

A conveying device and sorting technology, which is applied in the direction of solid separation, separation of solids from solids with airflow, recycling technology, etc., can solve problems such as waste of resources, high labor costs, inconvenient garbage disposal and reuse, etc., to achieve Effects of reducing dust pollution and noise pollution, improving processing speed and efficiency, and improving practicability and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

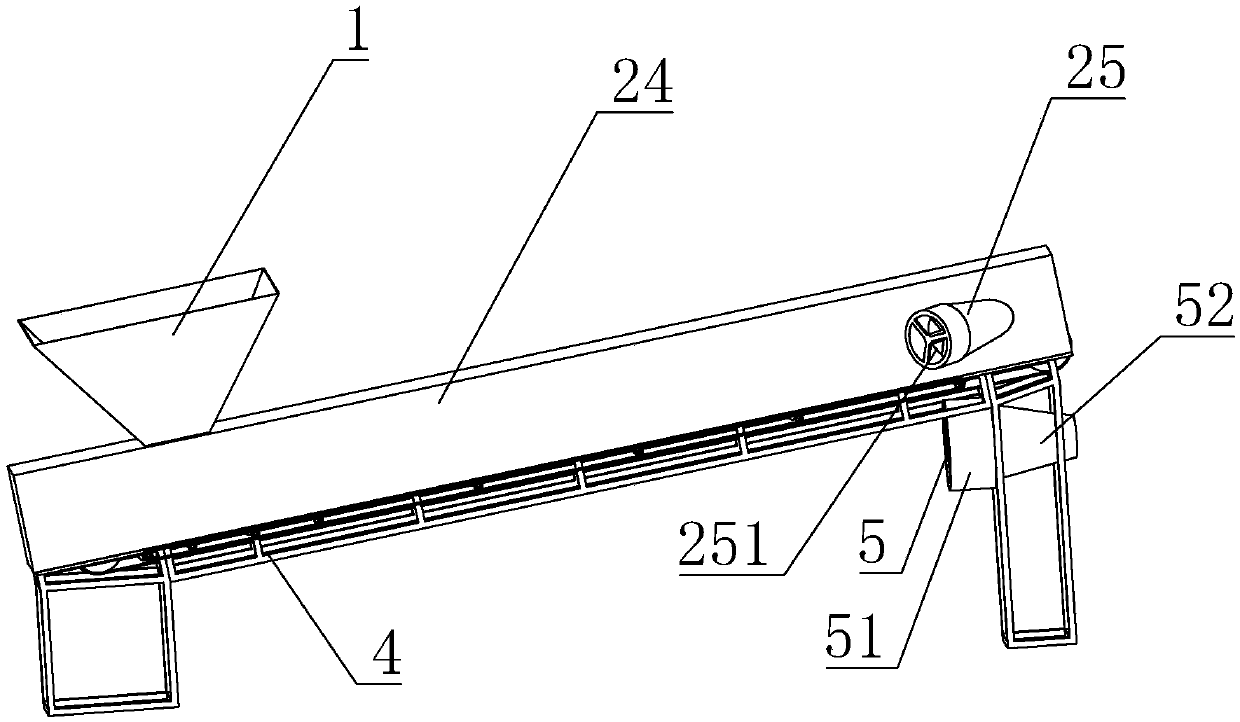

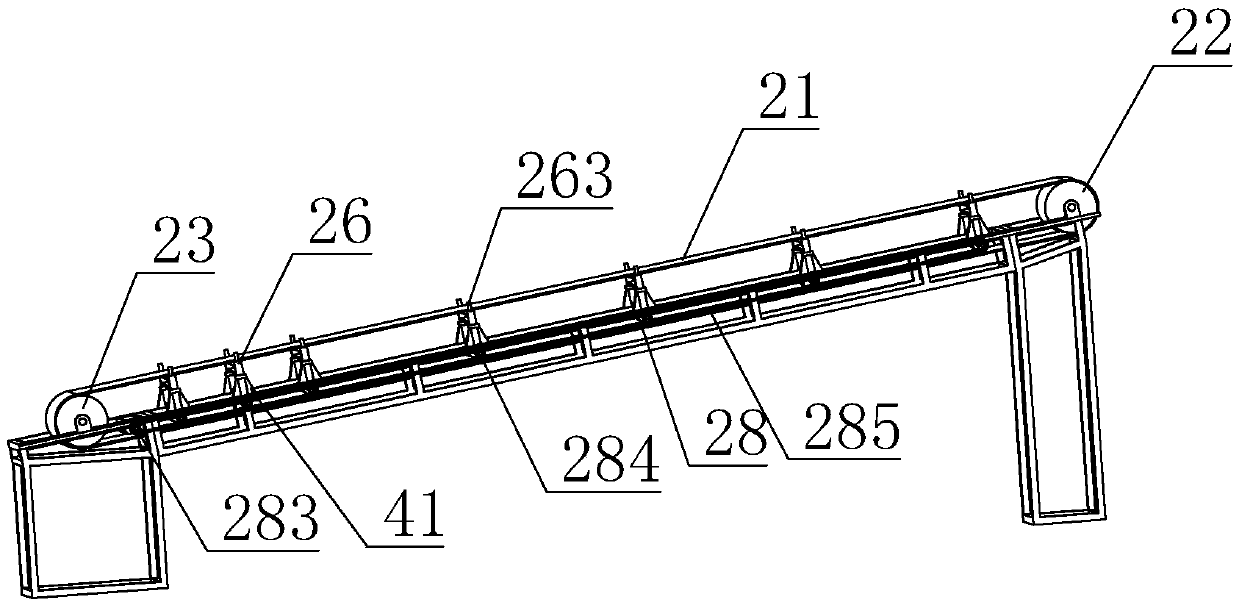

[0034] Example 1, please refer to Figure 1-6 , this embodiment discloses a garbage sorting and conveying device, including a frame 4, a conveying part and a sorting part. Driving wheel, conveyer belt 21 is tensioned on two driving wheels, and driving wheel rotatably is installed in the two ends of frame 4, and driving wheel 22 is installed in discharging end, and driven wheel 23 is installed in feeding end, and driving wheel 22 It is connected with the output shaft of the first motor, and rotates under the drive of the motor so as to drive the conveyor belt 21 to run and transport garbage. The sorting section includes a material throwing mechanism and an air supply mechanism, and the air supply mechanism includes a sealing cover 24 buckled above the conveyor belt 21, and an air inlet duct 25 symmetrically arranged on both sides of the sealing cover 24, and the air inlet duct 25 Built-in blower fan 251 is installed, and air inlet pipe 25 is a group and is arranged near the di...

Embodiment 2

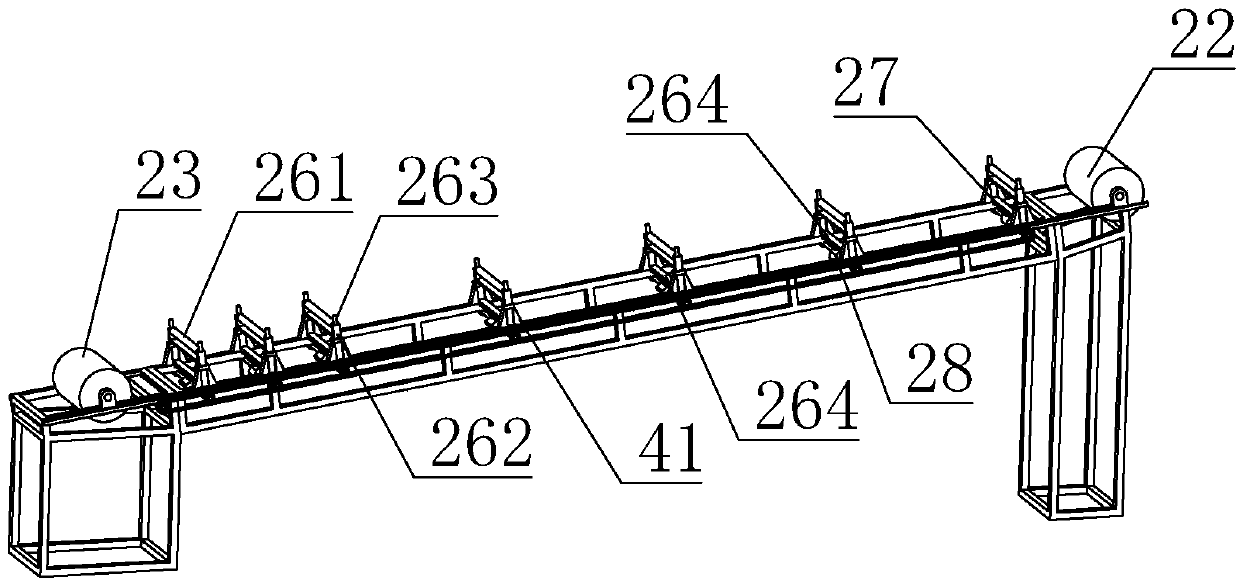

[0041] Embodiment two, see Figure 6-9 , this embodiment discloses a garbage sorting and conveying device, including a frame 4, a conveying part and a sorting part. Driving wheel, conveyer belt 21 is tensioned on two driving wheels, and driving wheel rotatably is installed in the two ends of frame 4, and driving wheel 22 is installed in discharging end, and driven wheel 23 is installed in feeding end, and driving wheel 22 It is connected with the output shaft of the first motor, and rotates under the drive of the motor so as to drive the conveyor belt 21 to run and transport garbage. The sorting section includes a material throwing mechanism and an air supply mechanism, and the air supply mechanism includes a sealing cover 24 buckled above the conveyor belt 21, and an air inlet duct 25 symmetrically arranged on both sides of the sealing cover 24, and the air inlet duct 25 A built-in fan 251 is installed, and the air inlet duct 25 is in multiple groups. In this embodiment, 3 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com