Board feeding device

A technology of boards and vertical boards, which is applied in the field of board loading and transportation, can solve the problems of time-consuming and laborious manual handling, affect the quality of boards, and have potential safety hazards, and achieve the effects of reducing bumps, maintaining physical safety, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

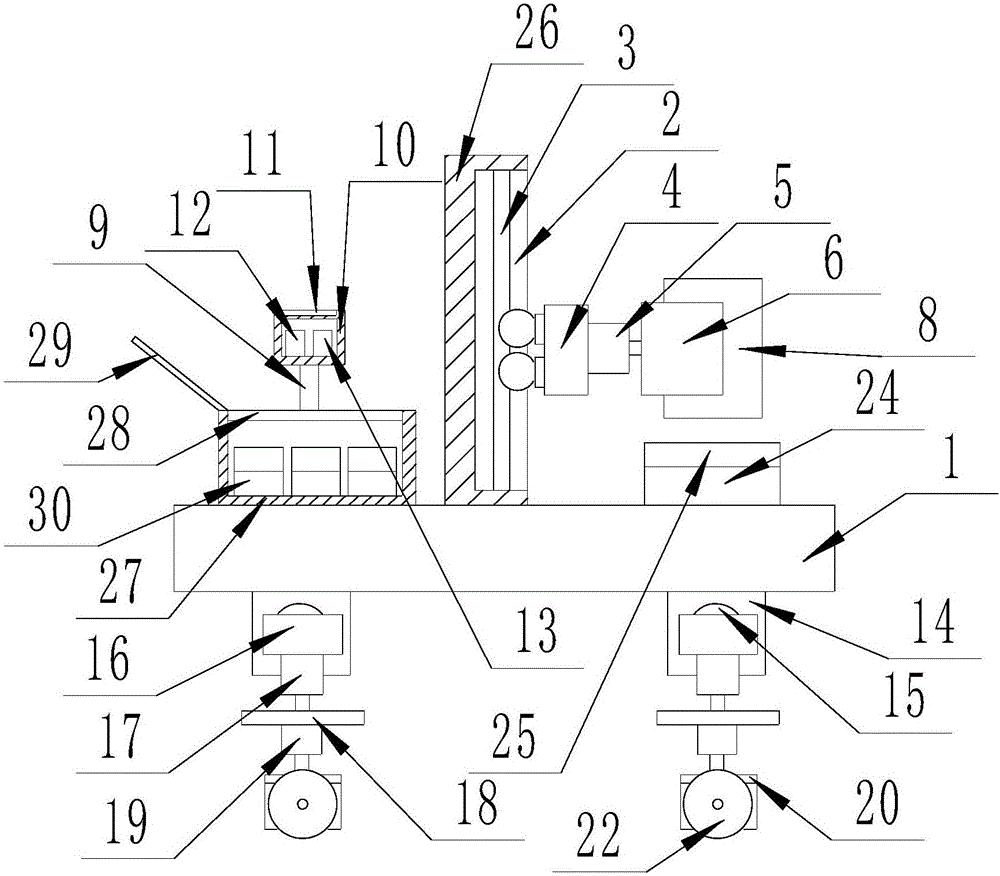

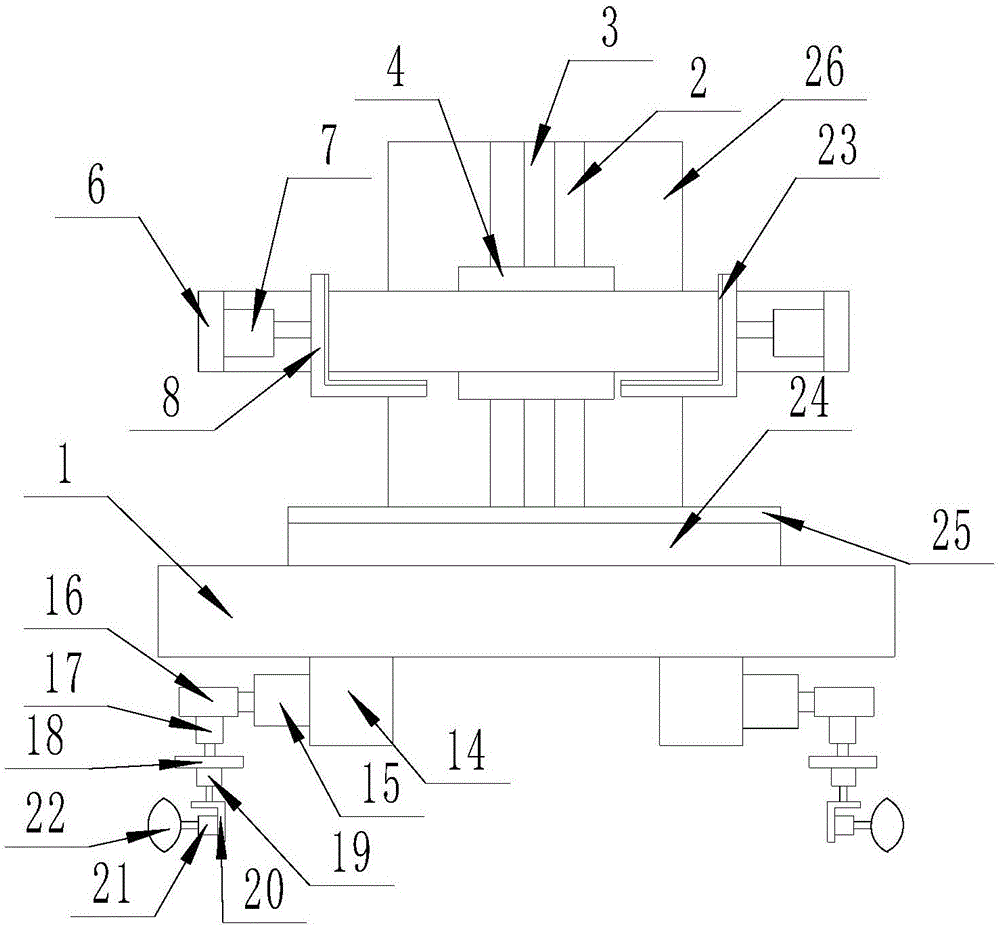

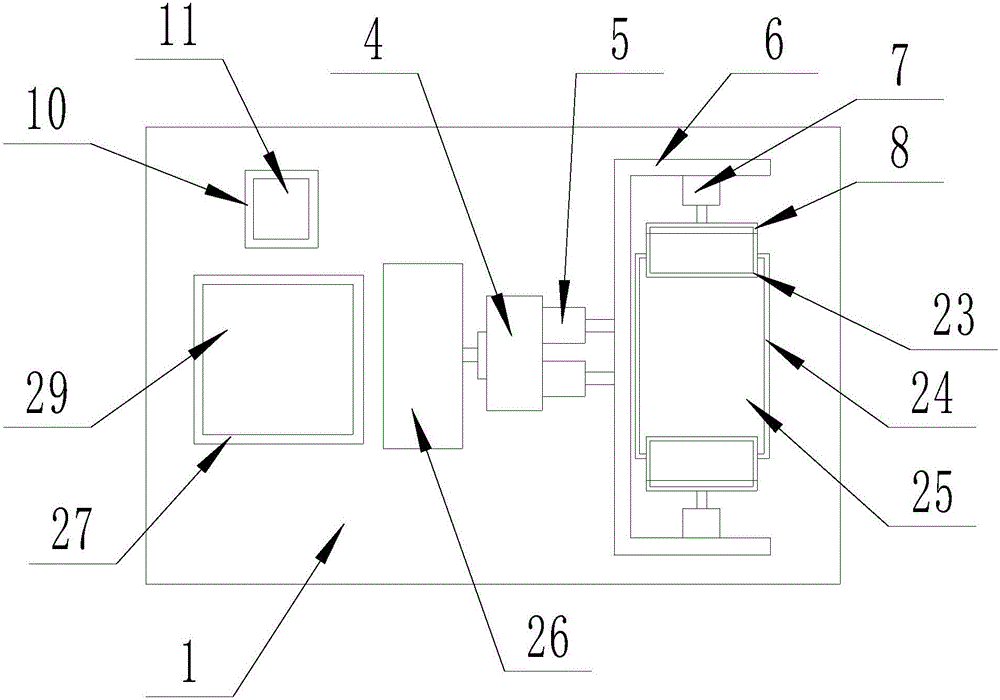

[0015] The present invention will be described in detail below with reference to the drawings, such as Figure 1-3 As shown, a plate loading device includes a carrying plate (1), a moving mechanism is provided on the lower surface of the carrying plate (1), and a mounting vertical plate (26) is provided on one side of the upper surface of the carrying plate (1) , A rectangular slide (2) is machined on one side surface of the mounting vertical plate (26), a slide rail (3) is provided in the rectangular slide (2), and an electric motor is provided on the slide rail (3). A trolley (4), the electric trolley (4) is provided with a group of telescopic cylinders (5) with a horizontal telescopic end, and the telescopic ends of each telescopic cylinder (5) are connected to a fixed frame (6). ), the fixed frame (6) is provided with a linear motor (7) with a horizontal telescopic end on the opposite side surface, and each linear motor (7) is provided with an L-shaped carrier plate (8) at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com