Air distribution system of rapid and energy-saving down-the-hole hammer for water well

A down-the-hole hammer, fast technology, applied in the direction of drilling driving device, drilling equipment, earthwork drilling and production in the wellbore, can solve the problems of small impact energy, large gas consumption, low working frequency, etc., and achieve single impact force The effect of large size, high working efficiency and high working frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

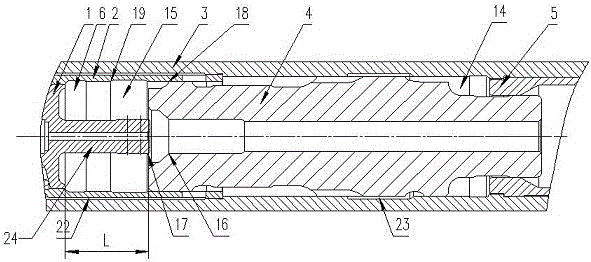

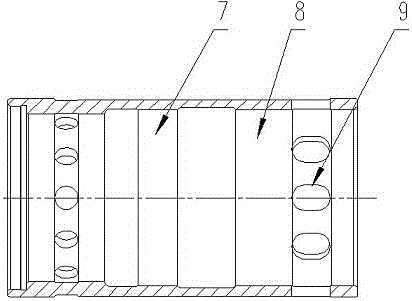

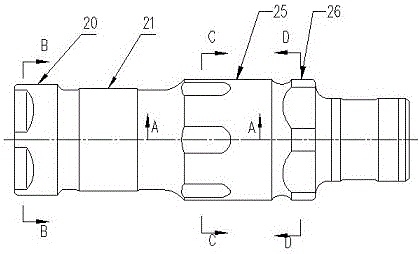

[0050] Examples such as Figure 1-7 As shown, the gas distribution system of a fast energy-saving down-the-hole hammer for water wells includes a cylindrical outer pipe 3, and a cylindrical inner cylinder 2 is set inside the outer pipe 3.

[0051] The outer surface of the inner cylinder 2 cooperates with the inner surface of the outer pipe 3 to form a general intake passage 22 of the gas distribution system.

[0052] The outer tube 3 is slidably connected with a piston 4, one end of the piston 4 is slidably connected to the inner cylinder 2, the other end of the piston 4 is set with a guide sleeve 5, and the guide sleeve 5 is fixedly connected in the outer tube 3, and the piston 4 and the guide sleeve 5 Swipe to connect.

[0053] The front air chamber 14 is formed by the cooperation of the piston 4 , the outer tube 3 and the guide sleeve 5 .

[0054] The outer surface of the piston 4 cooperates with the inner surface of the outer casing 3 to form a front air chamber inlet pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com