Circumferential axial negative pressure impact speeding-up tool

An axial and negative pressure technology, which is applied in the field of natural gas drilling and drilling speed-up, and oil field, can solve the problems of limited hammering force of impact hammer, complex flow channel structure, springing teeth, etc. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

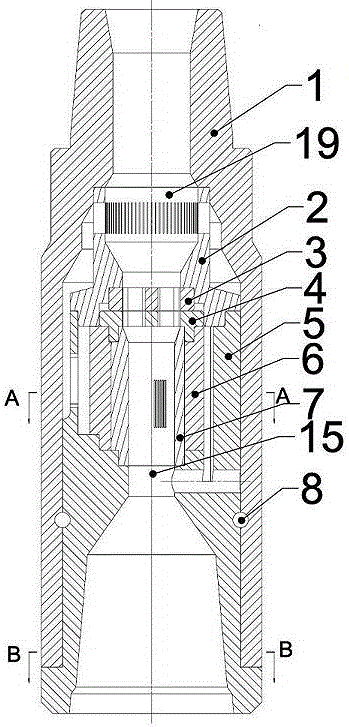

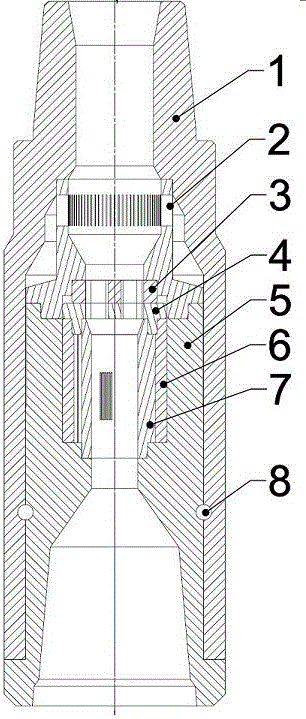

[0034] Such as Figure 1-2 Among them, a circumferential axial negative pressure impact speed-increasing tool, including an outer cylinder 1, a fixed valve seat 2, a fixed valve plate 3, a moving valve plate 4, an impact cylinder 5, an impact hammer 6, a reversing valve 7, and a ball bearing 8 ;

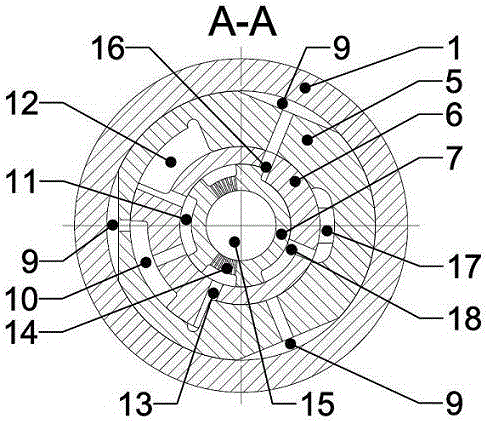

[0035] Such as image 3 Among them, a circumferential axial negative pressure impact speed-up tool is provided with a main valve and a control valve for reversing control. The inner wall surface of the impact cylinder 5 and the outer wall surface of the impact hammer 6 form the main valve, and the inner wall surface of the impact hammer 6 and the outer wall surface of the impact hammer 6 form the main valve. The outer wall of the reversing valve 7 constitutes a control valve;

[0036] Such as Figure 5 Among them, the outer wall of the impact cylinder 5 is provided with three high-pressure diversion grooves 9 and three diversion holes 21, and the inner wall is provided with an imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com