Ultrahigh-pressure hydraulic device integrating drilling, reaming and cutting

An ultra-high pressure, hydraulic technology, applied in the direction of earthwork drilling, discharge machinery, etc., can solve the problem of inability to realize the integration of drilling-reaming-slit, lack of anti-reflection means in hard coal seams, and poor anti-reflection effect of slots, etc. Problems, to achieve the effect of widely promoting the application value, the use effect is remarkable, and the effective scope of influence is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

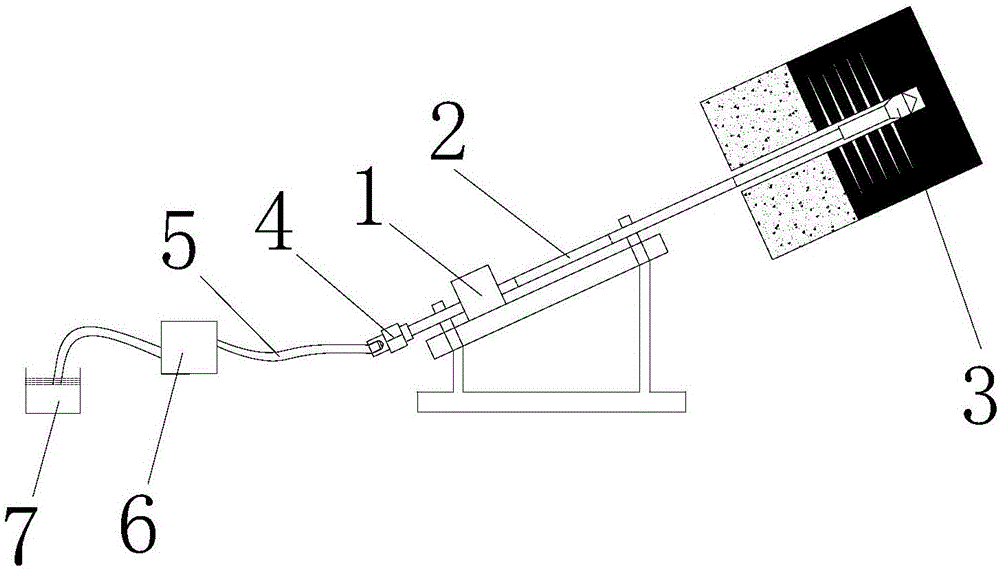

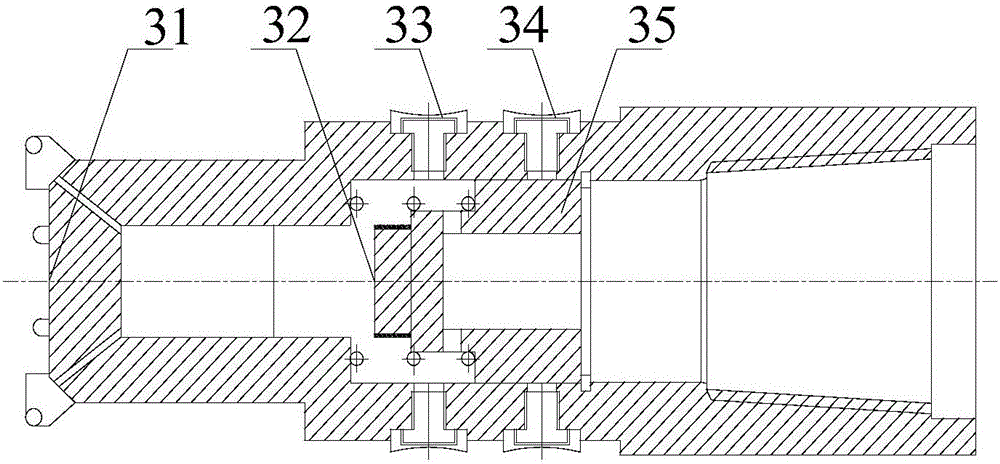

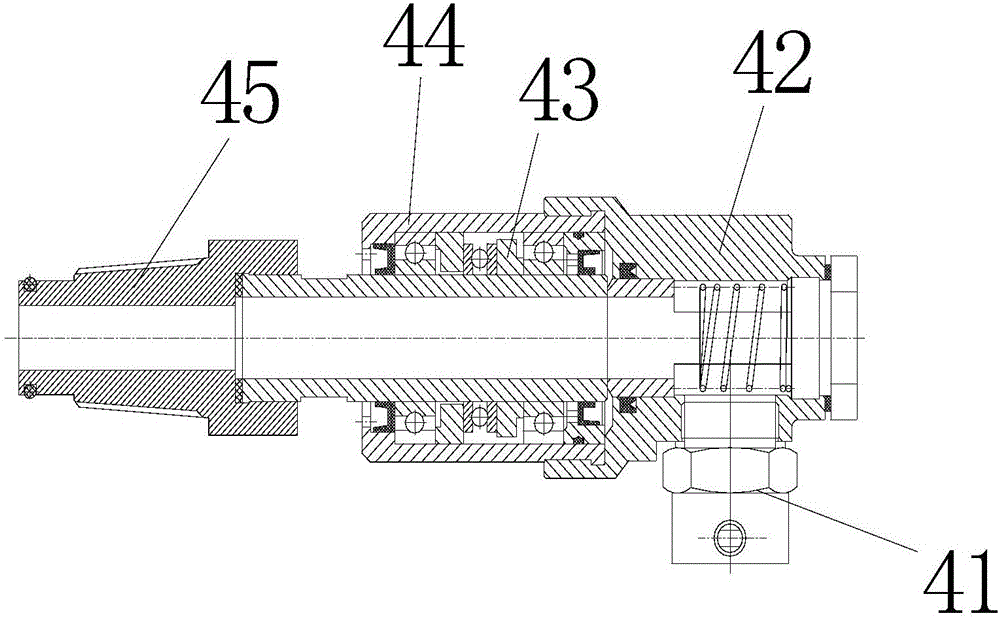

[0019] figure 1 It is a structural schematic diagram of the present invention; figure 2 A schematic diagram of the drill bit structure; image 3 is a schematic diagram of the structure of the rotating water tail; Figure 4 It is a schematic diagram of the drill pipe structure; as shown in the figure: the ultra-high pressure hydraulic drilling, expansion and cutting integrated device of the present embodiment includes a drilling machine 1, a rotating water tail 4, a drill pipe 2, a rubber hose 5, a drill bit 3, a water pump 6, and a water tank 7 The drill pipe 2 is installed on the drill rig 1 and driven to rotate by the turning machine, the drill bit 3 is fixed on the front end of the drill pipe 2; the rubber hose 5 is connected to the rear end of the drill pipe 2 through the rotating tail 4; the water pump 6 is connected to the water tank 7 and the rubber hose 5 are used to supply water to the drill pipe 2 and the drill bit 3 through the rubber hose 5; multiple nozzles are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com