Three-way catalytic converter for automobile exhaust

A catalytic converter and automobile exhaust technology, applied in the field of automobile exhaust three-way catalytic converter, can solve the problems of reduced life, uneven radial flow distribution, small heat load, etc. Improve the life of the catalyst and the effect of uniform radial flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

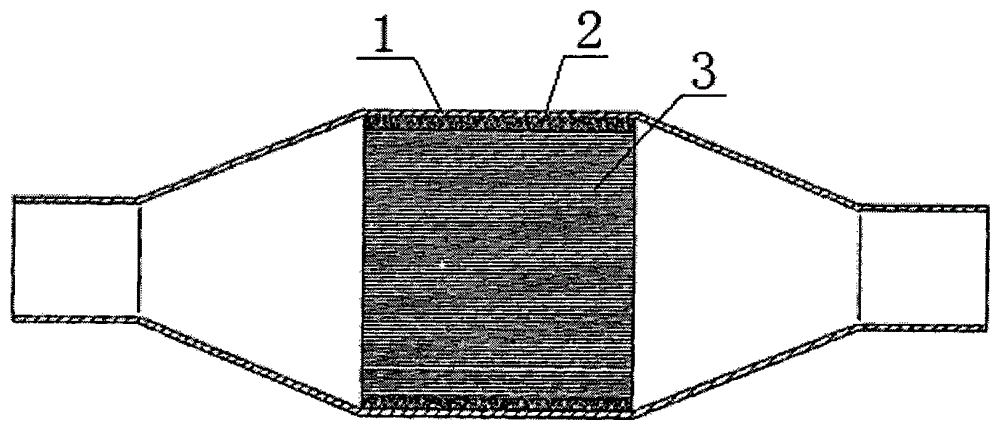

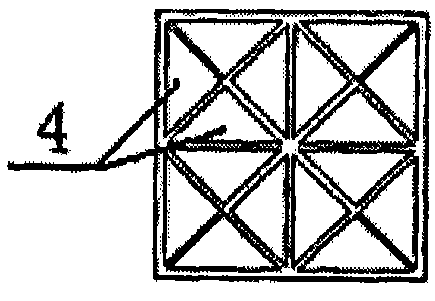

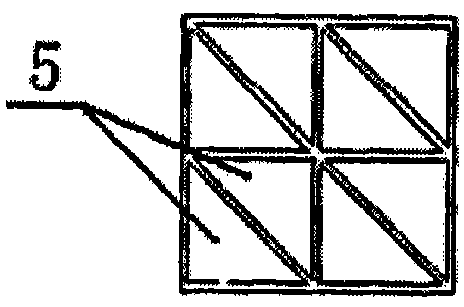

[0014] Such as Figure 1 to Figure 5 Shown, the three-way catalytic converter of the present invention comprises the casing 1 that carrier 3 is housed, is provided with damping layer 2 between casing 1 and carrier 3, and the channel section shape of carrier 3 is (referring to Figures 2 to 4 ): the central part 7 of the carrier 3 is a smaller isosceles right triangle 4, the outer layer 9 is a square 6, the middle part 8 between the central part 7 and the outer layer 9 is a larger isosceles right triangle 5, four The area of described less isosceles right triangle 4 is identical with the area of described square 6 and four described less isosceles right triangles 4 are arranged into a square, and the area of two described larger isosceles right triangles 5 and The area of the square 6 is the same and the two larger isosceles right triangles 5 are arranged to form a square, and the central part 7 is the radius R on the radial section of the carrier 1 ≤0.3R area, the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com