Drum brake for electric tricycle

A technology for drum brakes and electric tricycles, applied to drum brakes, brake types, brake discs, etc., can solve problems such as insufficient strength, deformation of bearing chambers, large torque, etc., to improve processing technology, ensure processing accuracy, The effect of reducing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

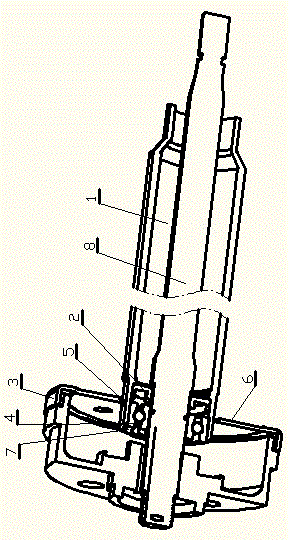

[0012] In the accompanying drawings, a drum brake for an electric tricycle includes a brake disc 3, a bridge tube 1 and a bearing 4; the bridge tube 1 is provided with a bearing positioning step 2, and the bearing positioning step 2 and the end face 7 of the bridge tube The center of the brake disc 3 is provided with a positioning hole 5 for installing the bridge tube 1, and the bridge tube 1 is inserted into the positioning hole 5 and fixed with the brake disc 3 by welding.

[0013] The positioning hole 5 is a single-diameter through hole whose diameter is equal to the outer diameter of the bridge tube 1 .

[0014] The distance between the bridge tube end face 7 and the outer end face of the brake disc is 4-40 mm.

[0015] During the welding operation, the direction of the welding seam is consistent with that of the positioning hole 5 and the welding groove is filled to ensure the strength of the welding seam.

[0016] Ensure that the radial position of the brake disc 3 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com