A carrier and carrier system for batch testing of photoelectric detectors

A photodetector, batch testing technology, applied in instruments and other directions, can solve the problems of low measurement efficiency, unfavorable for large-scale testing, time-consuming and labor-intensive, etc., and achieve the effect of rapid statistical analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

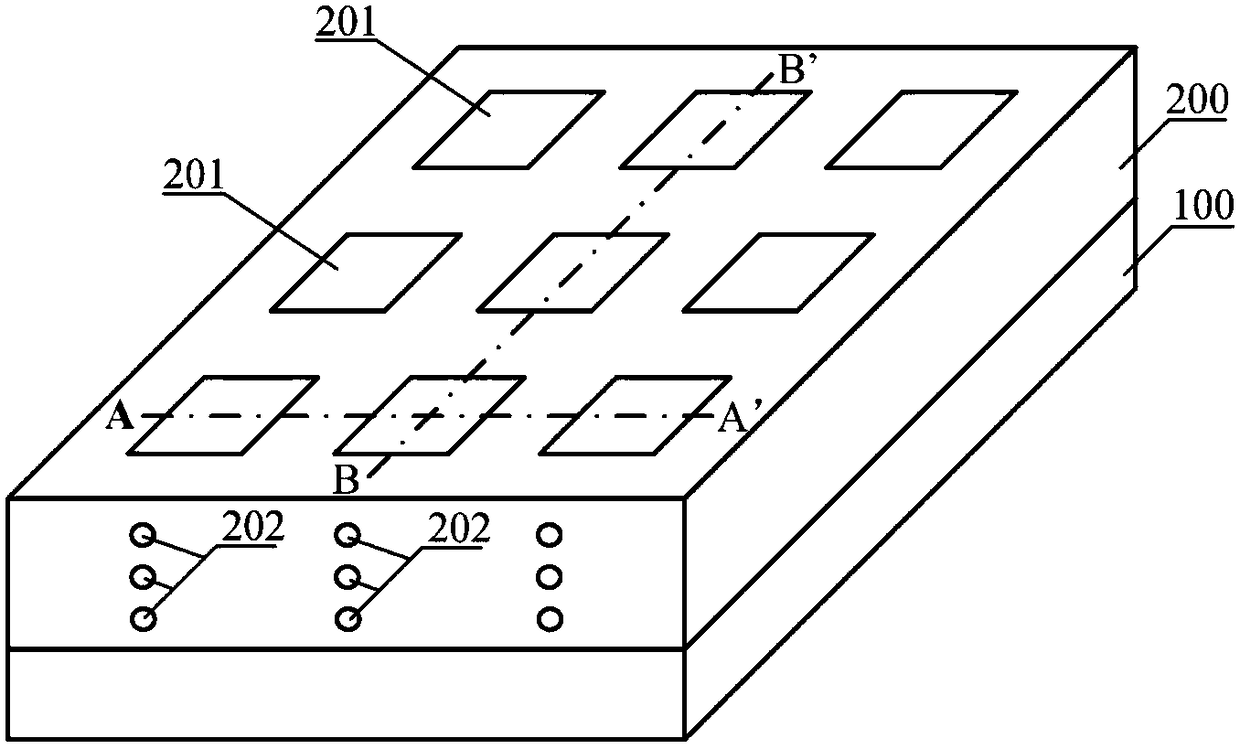

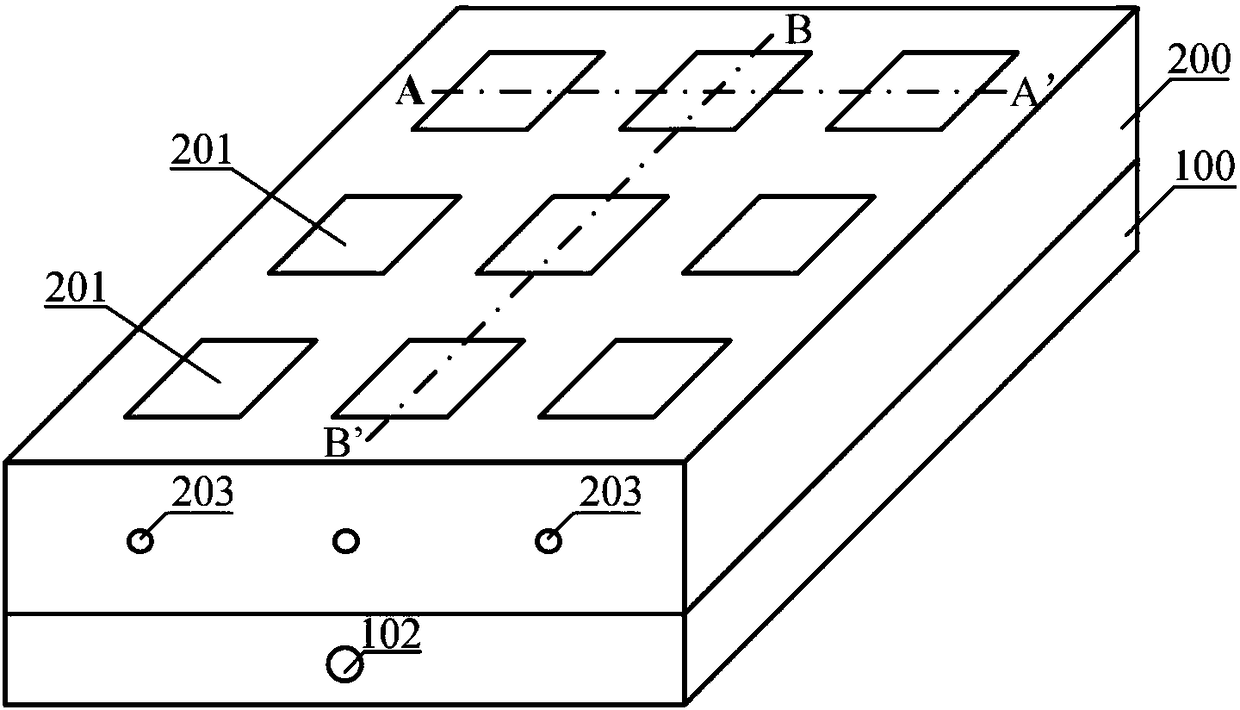

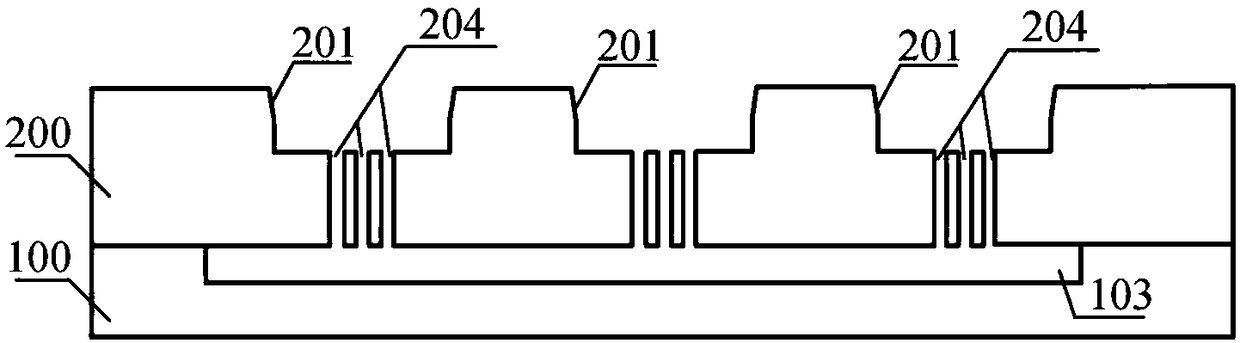

[0019] Please see attached figure 1 to attach Image 6. In order to realize the demand for fast and efficient measurement of the performance of photodetectors, the present invention provides a carrier and carrier system for batch testing of photodetectors, including a batch test carrier and a signal output interface (300) and a power input interface ( 400); the batch test carrier plate is sequentially provided with an air circuit layer (100) and a chip fixing layer (200) from bottom to top, and the air circuit layer (100) and the chip fixing layer (200) are hermetically connected; The road layer (100) includes an air cavity (103) and an air extraction hole (102), and the air cavity (103) is connected to the outside through the air extraction hole (102); the chip fixing layer (200) includes M rows and N columns (The values of M and N are both greater than or equal to 1. In this embodiment, both M and N are 3) Regularly arranged chip slots (201), and signal terminal metal po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com