Precise balancing correcting method for super-hard abrasive grinding wheel

A technology of superabrasives and correction methods, which is applied in static/dynamic balance testing, machine/structural component testing, measuring devices, etc., and can solve problems such as low work efficiency, sliding tendency of balance weights, and varying depths of deduplication holes. and other problems, to achieve the effect of quick correction, improved appearance quality, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

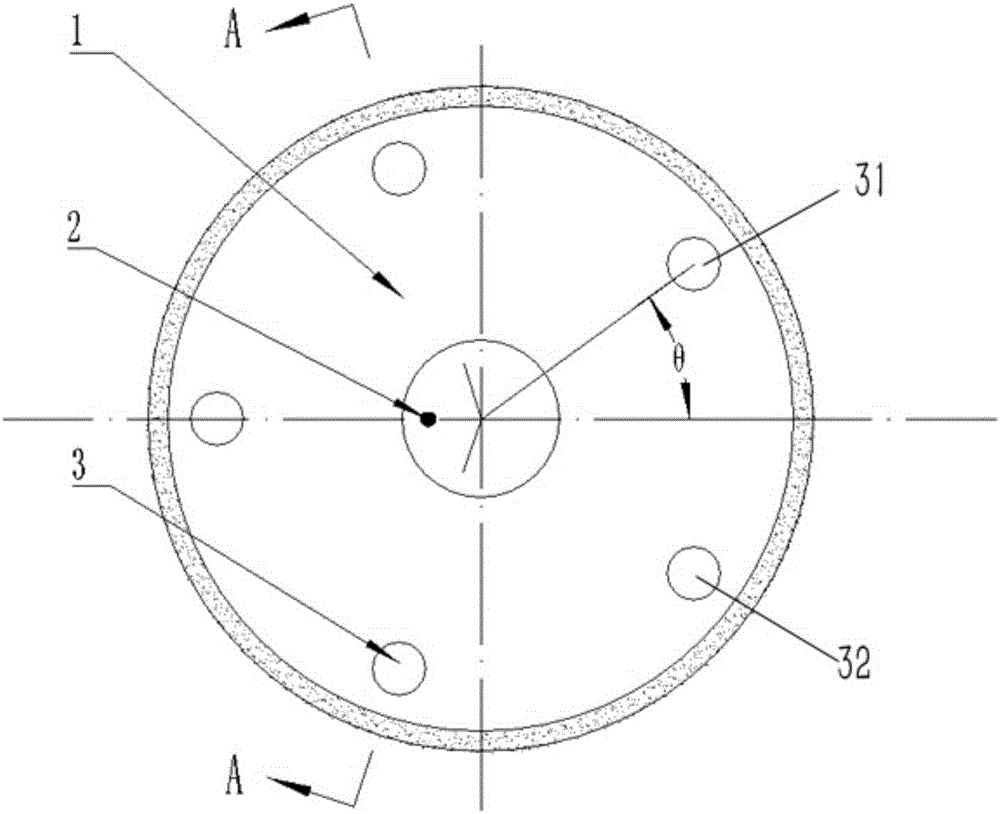

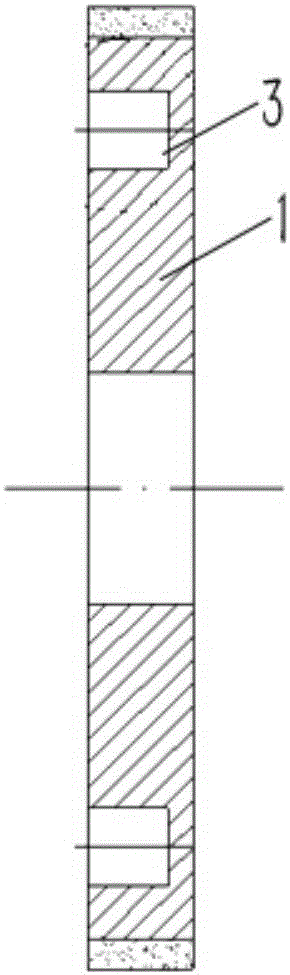

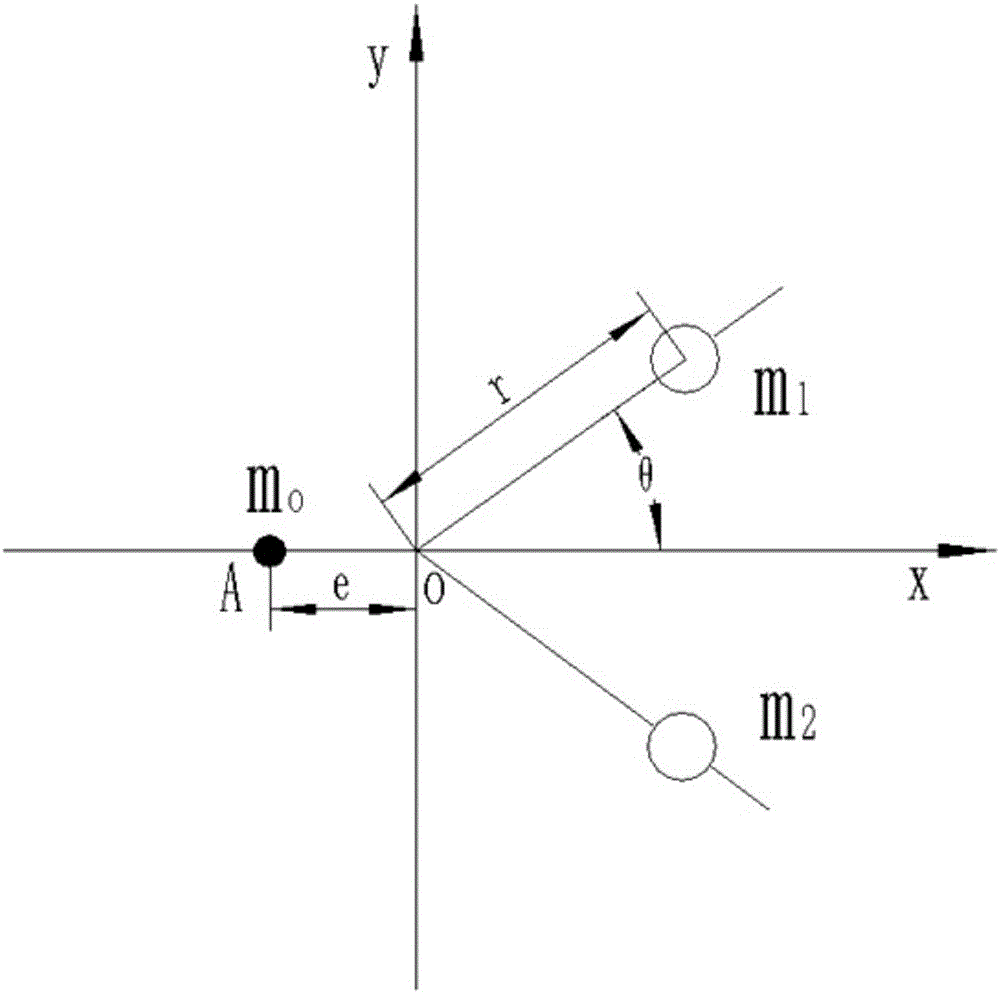

[0021] The embodiment of the precision balance correction method of superabrasive grinding wheel in the present invention: this method is a kind of precision balance correction method of superabrasive grinding wheel, is example with resin CBN flat grinding wheel, the outer diameter of this resin CBN flat grinding wheel is 200mm, inner The hole is 75mm and the thickness is 20mm. The resin CBN flat grinding wheel includes a grinding wheel base body 1 , a plug 6 and a counterweight 5 . Such as figure 1 and figure 2 As shown, the grinding wheel 1 is a superabrasive grinding wheel, and the base of the grinding wheel 1 is provided with balance holes 3 uniformly distributed along the circumferential direction. These balance holes 3 are used to place counterweights 5, and the counterweights 5 are classified according to their mass , the shape of the counterweight weight 5 is flake, and the counterweight weight 5 and the balance hole 3 are closely matched; the material of the counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com