Quick junction box for optical cables

A technology of fast switching and optical cables, applied in the direction of light guides, optics, optical components, etc., can solve the problems of poor seal of the transfer box, difficult troubleshooting, poor signal transmission quality, etc., to achieve good waterproof sealing effect and prevent moisture infiltration , the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

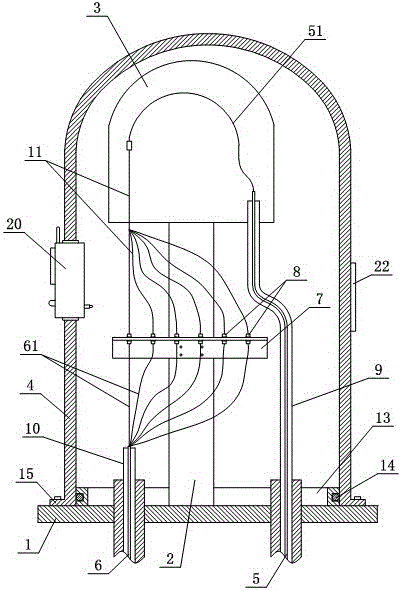

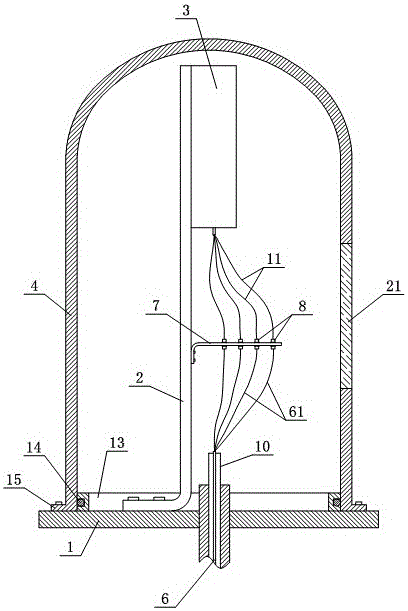

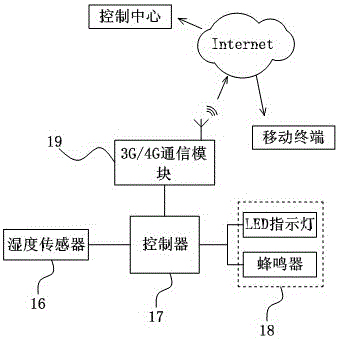

[0028] Referring to the accompanying drawings, the optical cable quick transfer box of the present invention includes a base 1, an optical fiber splicing tray 3 mounted on the base 1 through a bracket 2, and a buckle cover 4 packaged on the base 1 and incorporating the optical fiber splicing tray 3 therein. The incoming line 5 and the optical cable outgoing line 6 are fixed on the base 1 respectively. The optical fiber flange fixing frame 7 is also installed on the base 1. The optical fiber fusion splicing tray 3 is fixed on the top of the bracket 2, and the optical fiber flange fixing frame 7 is fixed on the bracket. 2 middle. A plurality of optical fiber flanges 8 are installed on the optical fiber flange fixing frame 7 . The base 1 is equipped with a vertically arranged incoming line protection tube 9 and an outgoing line protection tube 10 . The cable inlet 5 is installed in the inlet protection tube 9 and after passing through the inlet and outlet protection tube 9, a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com