Winding method of a high voltage coil

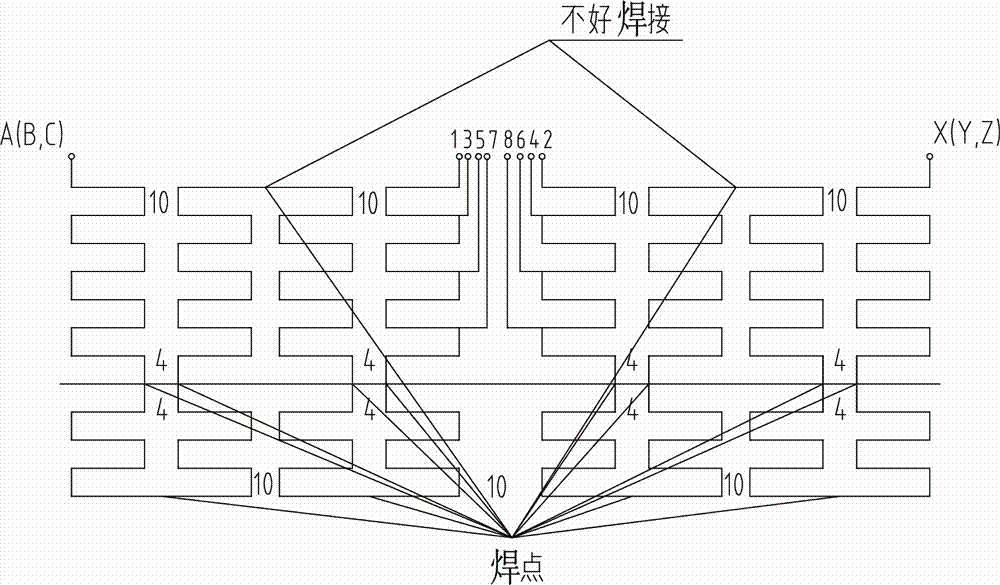

A high-voltage coil and winding method technology, applied in the field of transformers, can solve the problems of difficult welding, burning coils, easy falling of welding, etc., and achieve the effects of avoiding high welding difficulty, enhancing reliability, and ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

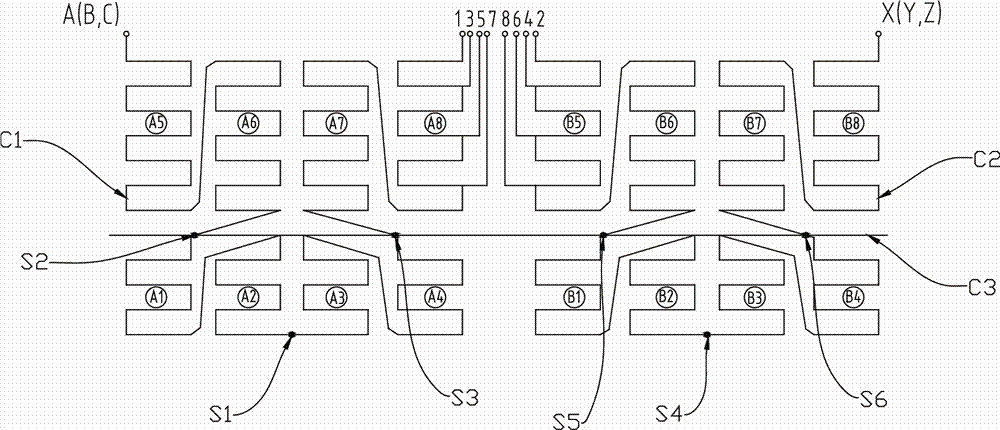

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] See Figure 1 to Figure 2 , a high-voltage coil winding method, including a symmetrical structure of the first winding coil C1 and the second winding coil C2, air channel plate C3; the first winding coil C1 includes the first welding point S1, the second Second welding spot S2, third welding spot S3, first coil A1, second coil A2, third coil A3, fourth coil A4, fifth coil A5, sixth coil A6, seventh coil A7, eighth coil A8 , the second winding coil C2 includes a fourth welding spot S4, a fifth welding spot S5, a sixth welding spot S6, a ninth coil B1, a tenth coil B2, an eleventh coil B3, a twelfth coil B4, The thirteenth coil B5, the fourteenth coil B6, the fifteenth coil B7, and the sixteenth coil B8; the steps are as follows:

[0023] Step a: Wind the wire from the first welding point S1 to the third coil A3, wind it to the airway pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com