Wafer support ring, wafer support jig and wafer processing equipment

A technology for wafer processing and support rings, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc. It can solve problems such as the inability to ensure consistent wafer temperature, lower chip yield, and cumbersome adjustment process, and achieve simple structure and easy operation , the effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

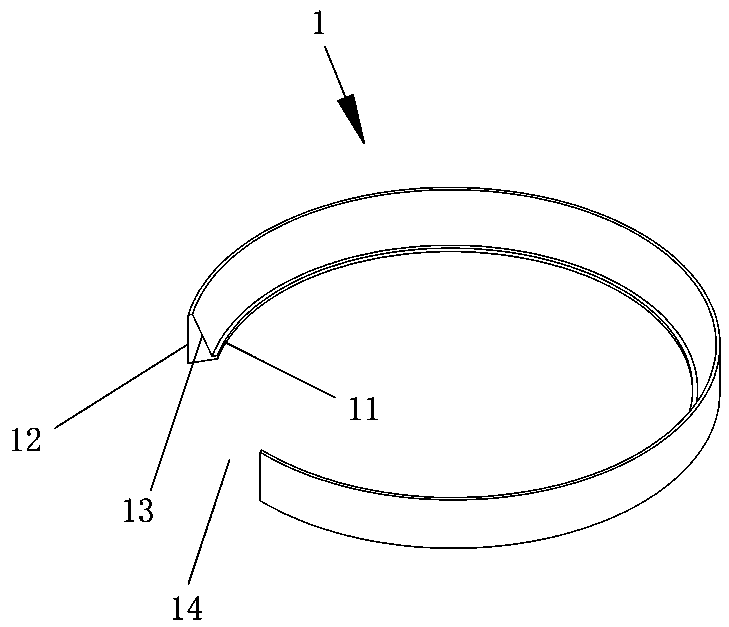

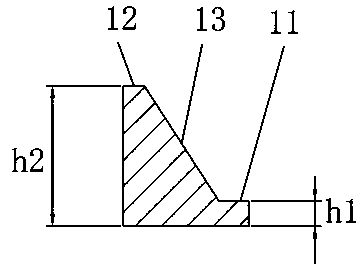

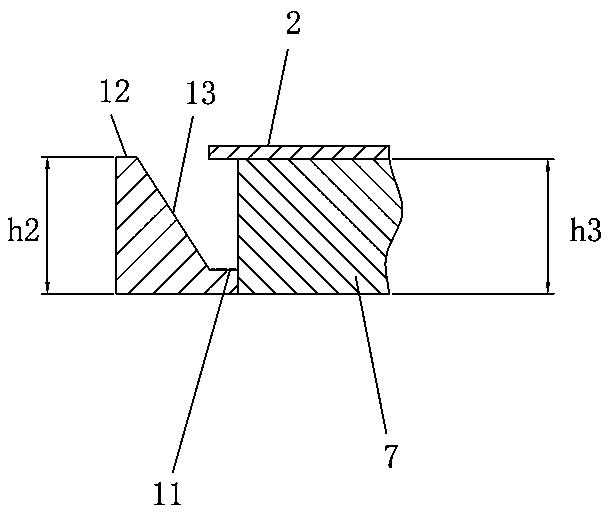

[0027] Such as Figure 1 to Figure 3 As shown, the wafer support ring of the present embodiment includes a support ring body 1, and the support ring body 1 includes an outer ring portion 12 and an inner ring portion 11 for supporting the wafer 2, the height of the inner ring portion 11 is h1, and the outer ring portion The height of 12 is h2, h1<h2, the outer side of the upper surface of the inner ring part 11 and the inner side of the upper surface of the outer ring part 12 are transitionally connected by a slope 13, the wafer support ring is provided with an inner ring part 11 for placing the wafer 2, and the inner ring part The flatness of the part 11 can be guaranteed by the machining accuracy, so as to ensure the accurate positioning of the wafer 2, without complicated adjustments, and easy to use. The inner ring part 11 can provide effective support for the outer peripheral part of the wafer 2, and the contact area is larger and the force is more uniform , reducing fragm...

Embodiment 2

[0030] Such as Figure 4 with Figure 5 As shown, the wafer support ring of this embodiment is basically the same as that of Embodiment 1, the difference is that the height difference between the inner ring portion 11 and the outer ring portion 12 is relatively small, and accordingly, the specification of the inclined surface 13 is also reduced. The processing difficulty of the wafer support ring is reduced.

[0031] Such as Image 6 As shown, the wafer supporting fixture of this embodiment includes a reinforcing ring 4, a connecting rod 5 and the above-mentioned wafer supporting ring, the reinforcing ring 4 is located below the supporting ring body 1, the upper end of the connecting rod 5 is fixedly connected to the supporting ring body 1, and the connecting rod 5. The lower end is fixedly connected with the reinforcement ring 4. The wafer support fixture includes the above-mentioned wafer support ring, so it also has the advantages of the wafer support ring, and has a simp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com