Waste power battery disassembly device and method

A power battery and waste technology, which is applied in the field of used power battery dismantling devices, can solve the problems of different composition and recycling methods, hidden dangers of manual operation, inconvenient automatic disassembly, etc., to improve user efficiency, reduce labor intensity, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples are a further description of the content of the present invention as an explanation of the technical content of the present invention, but the essential content of the present invention is not limited to the following examples, those of ordinary skill in the art can and should know any Simple changes or replacements of the essential spirit of the invention shall fall within the scope of protection required by the present invention.

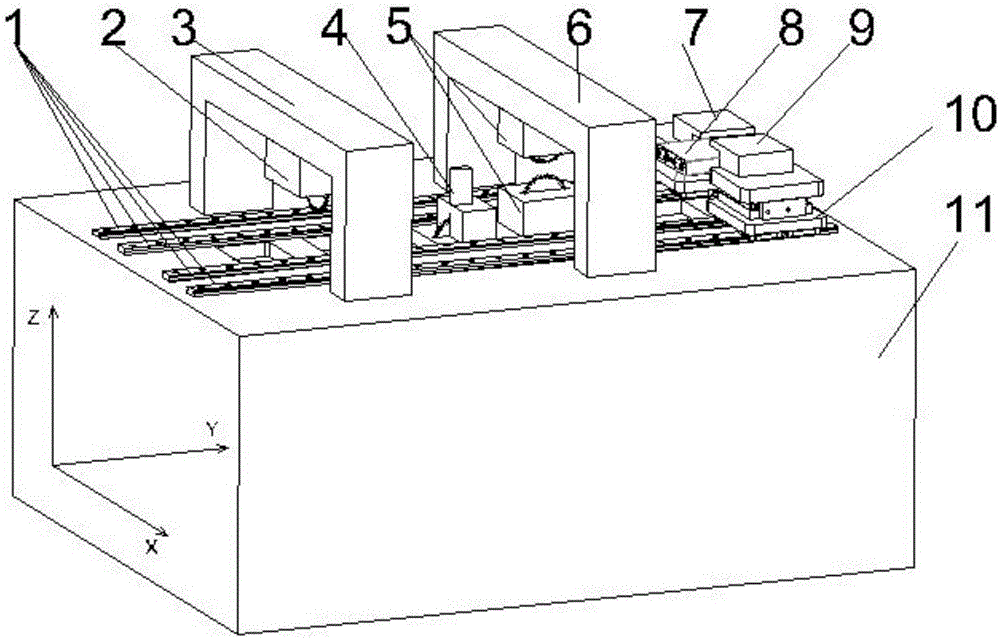

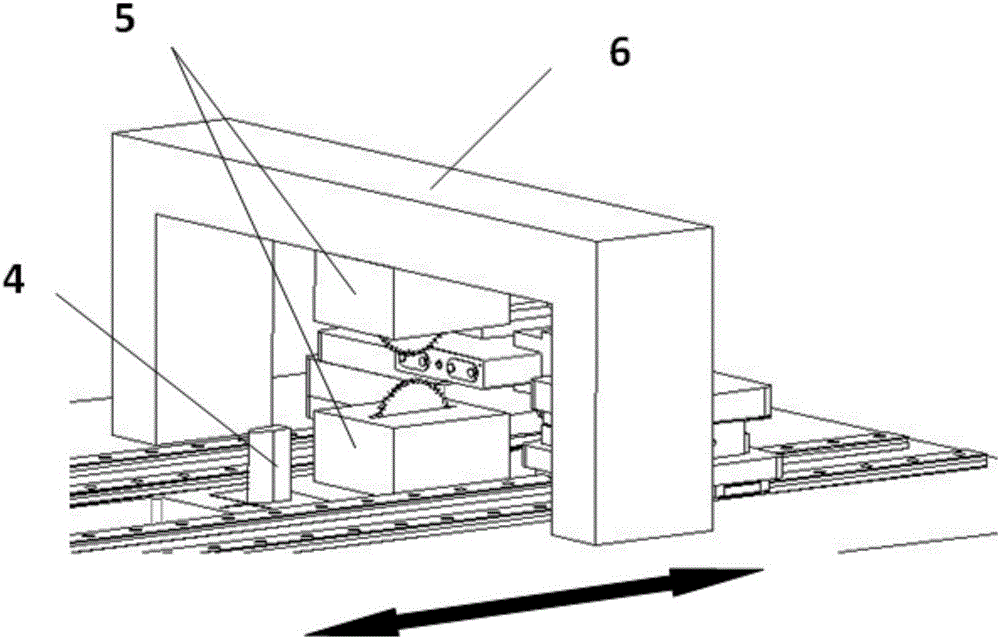

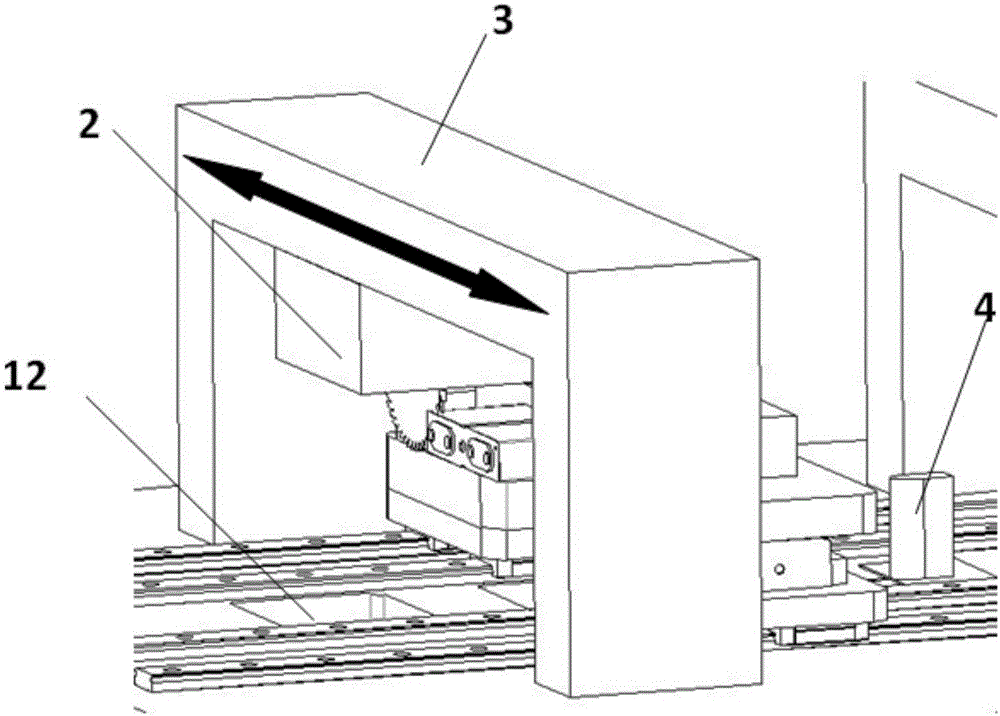

[0031] A dismantling device for waste power batteries, such as figure 1 As shown, the structure includes: 1. Jaw moving track, 2. Cover plate cutting device, 3. Gantry frame I, 4. Tail cutting and coring device, 5. Upper and lower cutting device, 6. Gantry frame II, 7. Clip Claw I, 9. Gripper II, 10. Telescopic device, 11. Base, 15. Rolling core, 16. Shell, the base 11 is provided with a cover plate recovery port 12, a cell recovery port 13 and a shell recovery port 14.

[0032] The jaw moving track 1 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com