Constant temperature and humidity power distribution cabinet

A constant temperature and humidity, power distribution cabinet technology, used in electrical components, non-electric variable control, machines using electrical/magnetic effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

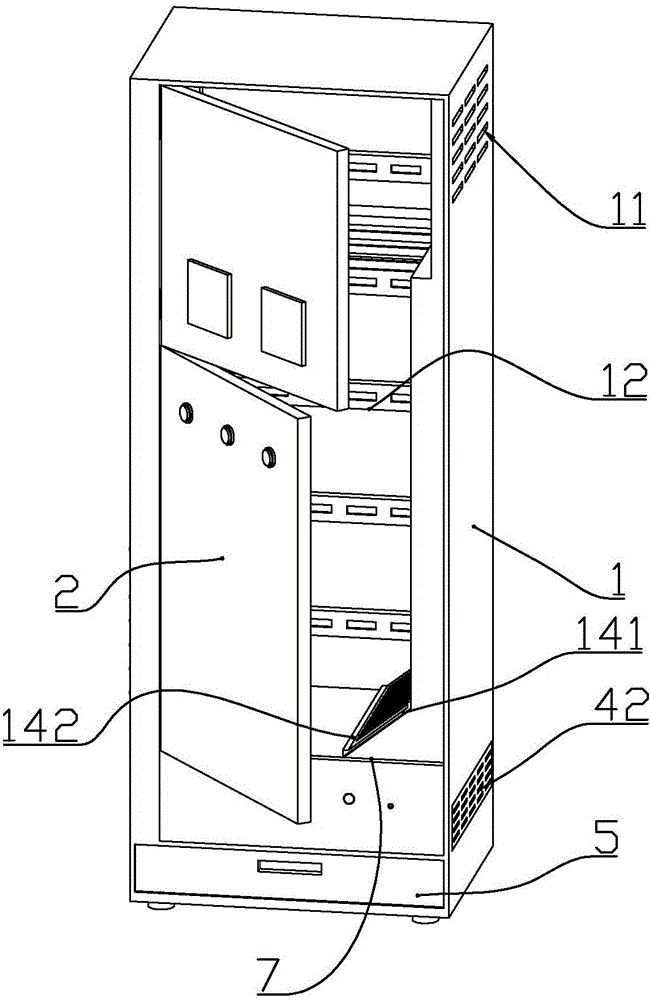

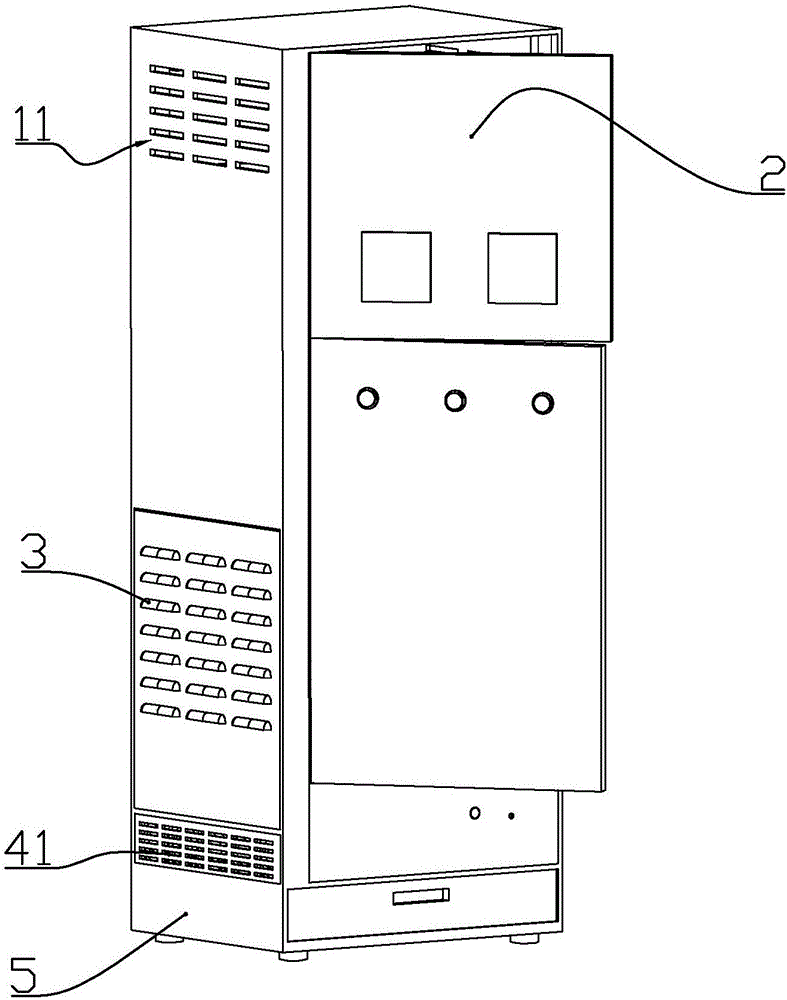

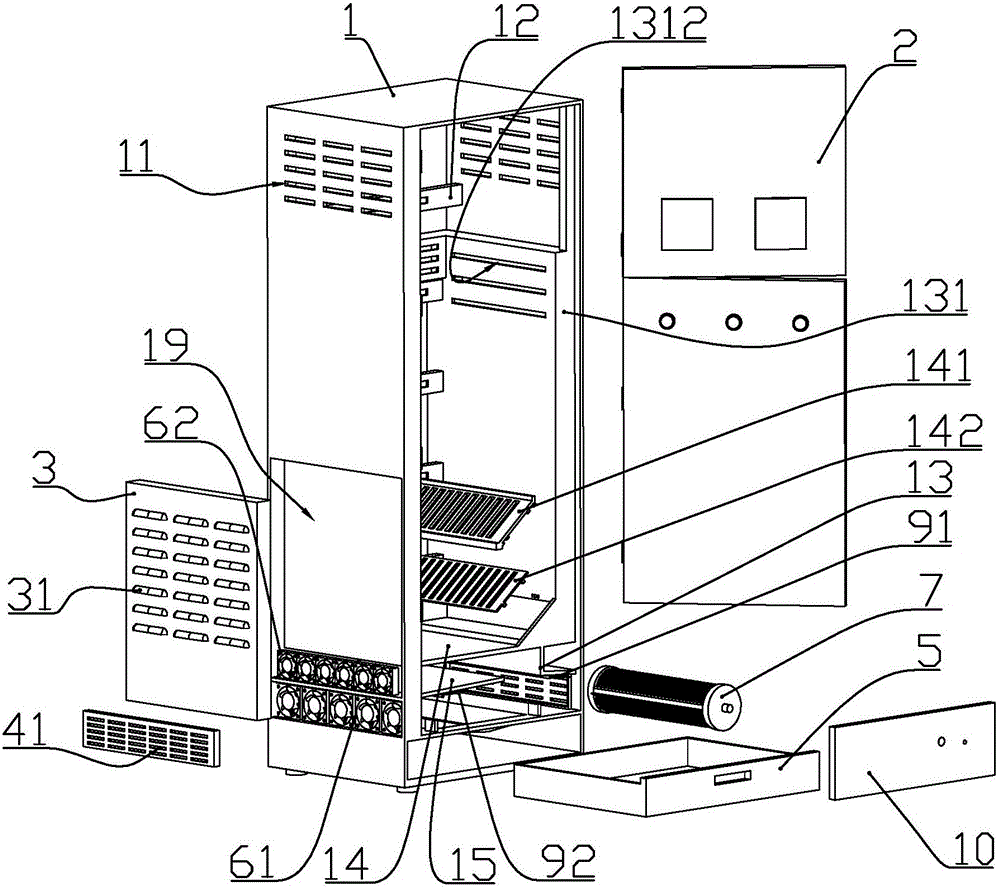

[0071] according to Figure 1 to Figure 17 As shown, this embodiment is a constant temperature and humidity power distribution cabinet, including a cabinet body 1 with a front opening, and a cabinet door 2 connected to the front end of the cabinet body through hinges; a mounting frame 12 is installed at the rear of the cabinet body ; The left and right sides of the upper part of the cabinet are formed with air outlets 11 .

[0072] The bottom of the cabinet body is formed with a slope plate 16 that is high on both sides and low in the middle; in the cabinet, the rear side of the cabinet is the rear cabinet, and the bottom of the rear cabinet is located above the middle of the slope. A stepper motor 8 is installed. The output shaft of the stepping motor is connected with a cooling plate assembly 7 arranged horizontally along the front and back direction of the cabinet.

[0073] The cooling chip assembly 7 includes two circular end blocks 74 of plastic material, more than one s...

Embodiment 2

[0089] according to Figure 1 to Figure 17 As shown, this embodiment is a constant temperature and humidity power distribution cabinet, including a cabinet body 1 with a front opening, and a cabinet door 2 connected to the front end of the cabinet body through hinges; a mounting frame 12 is installed at the rear of the cabinet body ; The left and right sides of the upper part of the cabinet are formed with air outlets 11 .

[0090] The bottom of the cabinet body is formed with a slope plate 16 that is high on both sides and low in the middle; in the cabinet, the rear side of the cabinet is the rear cabinet, and the bottom of the rear cabinet is located above the middle of the slope. A stepper motor 8 is installed. The output shaft of the stepping motor is connected with a cooling plate assembly 7 arranged horizontally along the front and back direction of the cabinet.

[0091] The cooling chip assembly 7 includes two circular end blocks 74 of plastic material, more than one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com