Ultra high voltage SF6 gas-insulated wall feed-through sleeve

A gas insulation, wall bushing technology, applied in insulators, lead-in/through insulators, electrical components, etc., can solve the problems of large moment at the root of the outer insulation, difficult to handle insulation support, low bending strength, etc. Effects of flashover voltage, reduced production difficulty, and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with examples. However, the invention is not limited to the examples given.

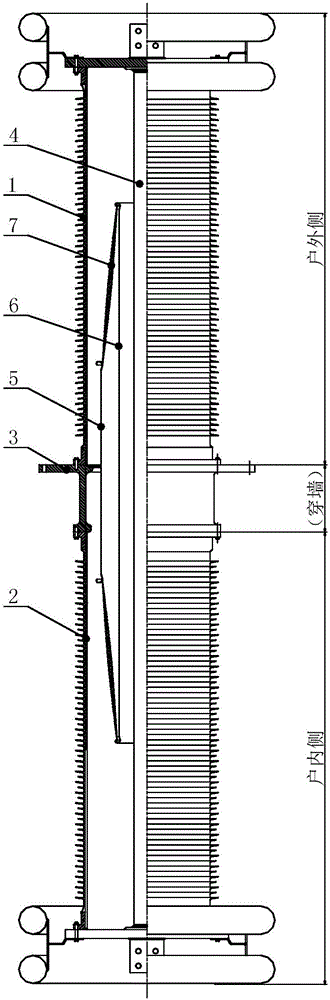

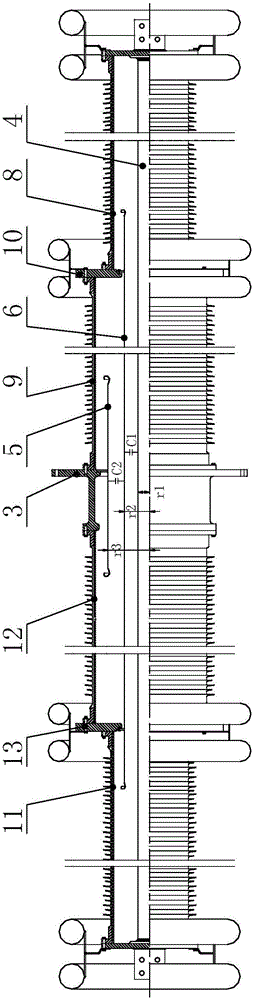

[0025] Such as figure 2 As shown, the UHV composite external insulation wall bushing of this embodiment includes an external insulation structure and an electrode structure disposed inside the external insulation structure. Its outer insulating structure includes: an indoor insulating sleeve and an outdoor insulating sleeve connected as one through the mounting flange 3 , and its electrode structure includes: a conductive rod 4 , an intermediate electrode 6 and a grounding electrode 5 . The conductive rod 4 is arranged in the center of the outer insulating structure, the ground electrode 5 is installed on the mounting flange 3 , and the middle electrode 6 is interposed between the conductive rod 4 and the ground electrode 5 .

[0026] The insulation sleeve of the present invention adopts a segmented structure, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com