Magnetic flux modulation dual-stator dual-electric-port motor

A magnetic flux modulation and double stator technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of complex structure and distribution, reduce frequency converters, etc., and achieve flexible four-quadrant control, high transmission efficiency, and high torque transmission capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

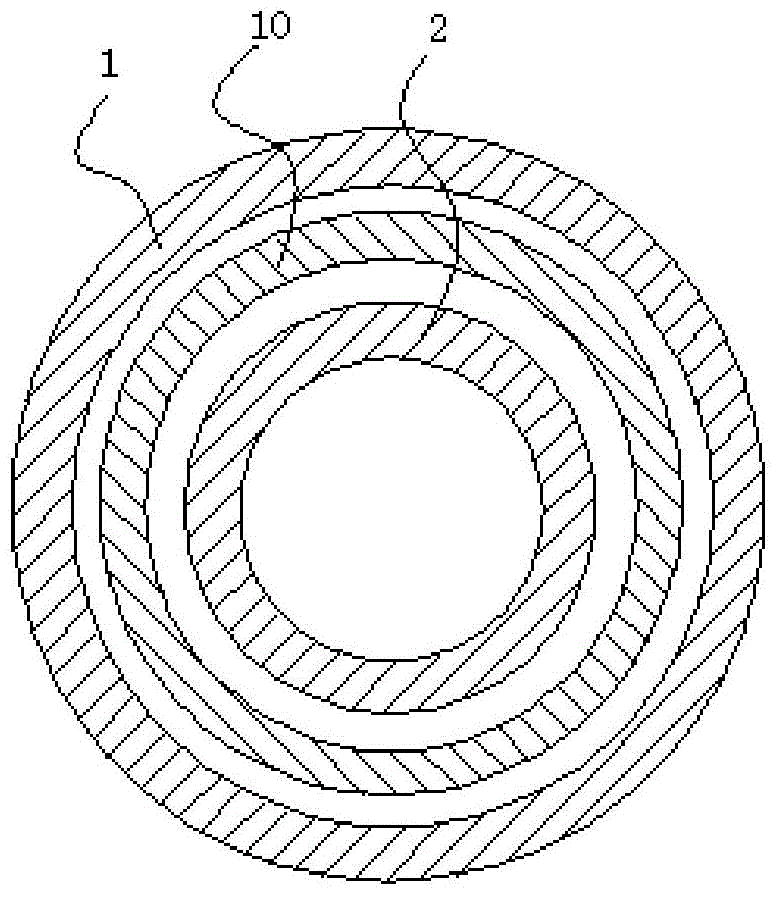

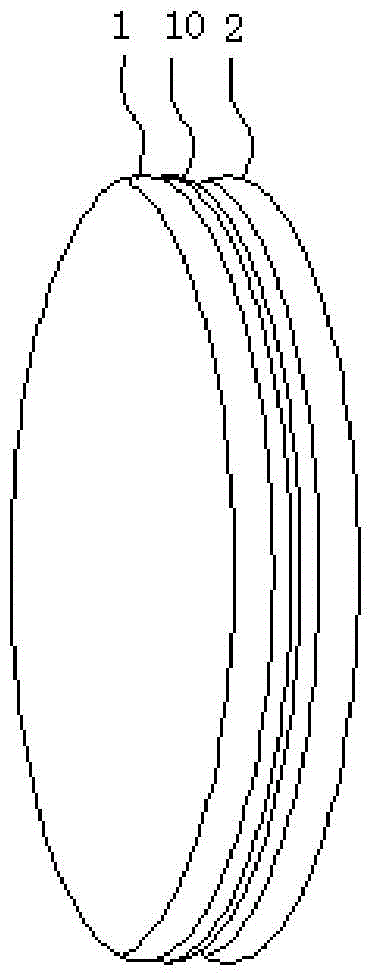

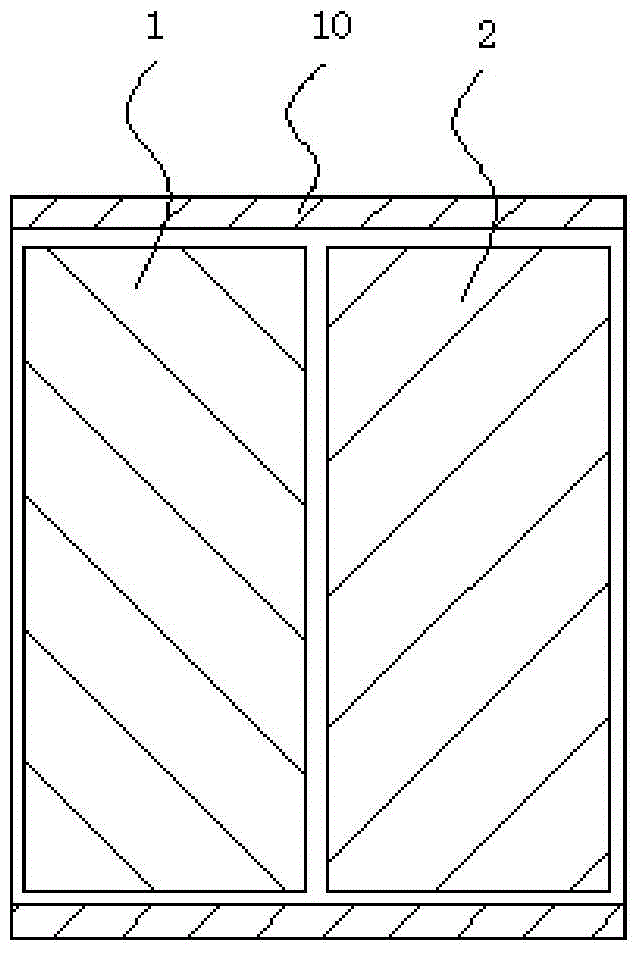

[0033] refer to Figure 1-3 , the magnetic flux modulation dual-stator dual-electric port motor of the present invention mainly includes coaxially arranged and mutually independent: a first stator 1, a second stator 2, a magnetic modulation ring 10, the first stator 1 and the second There is an air gap between the stators 2, and the magnetic modulation ring 10 can rotate freely, and the magnetic modulation ring 10 is set in the air gap between the first stator 1 and the second stator 2 or is set between the first stator 1 and the second stator 1. In the air gap outside the two stators 2, the magnetic fields generated by the first stator 1 and the second stator 2 are modulated and rotated, and then the torque is transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com