A shell and its preparation method

A technology of shell and decorative layer, applied in the direction of cabinet/cabinet/drawer parts, etc., can solve the problem of easy wear and tear of the decorative surface of the shell, and achieve the effect of achieving diversity and good texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

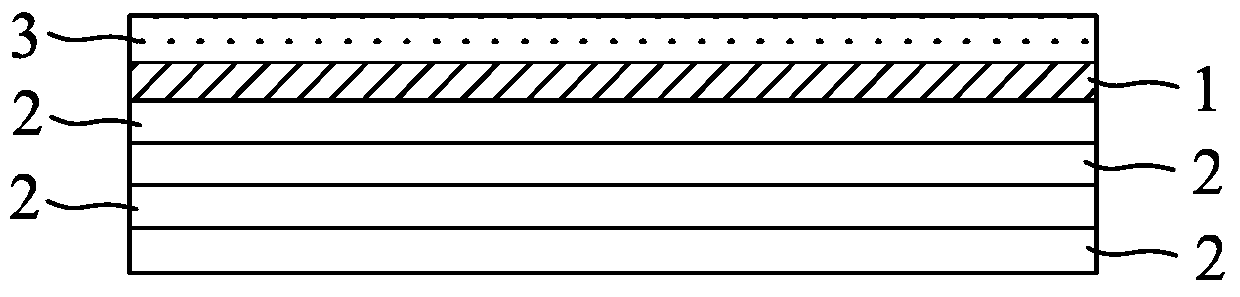

[0027] At the same time, the present invention also provides a method for preparing the above shell, which is characterized in that it includes the following steps:

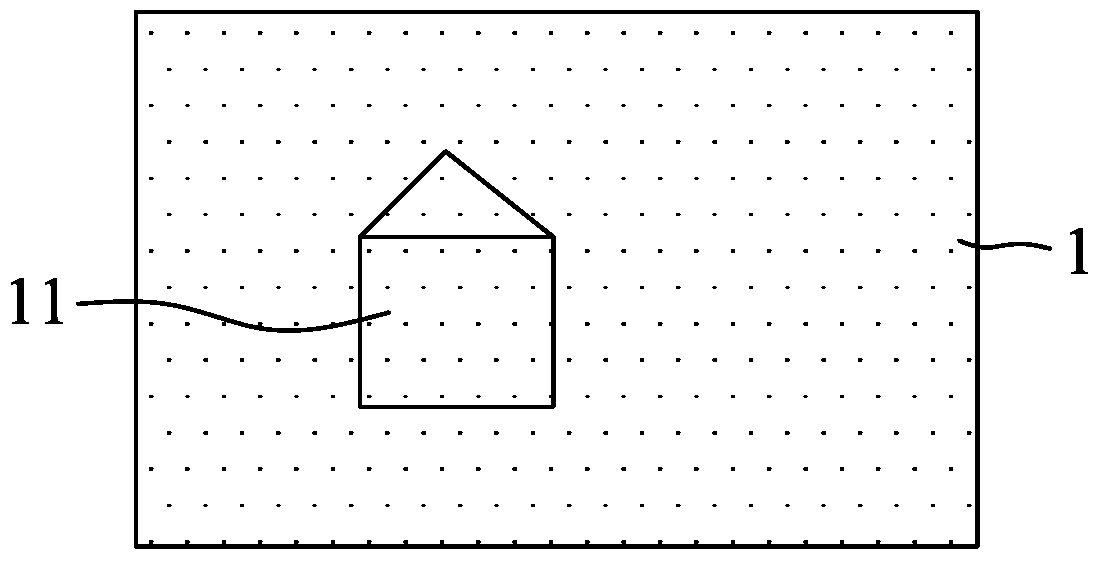

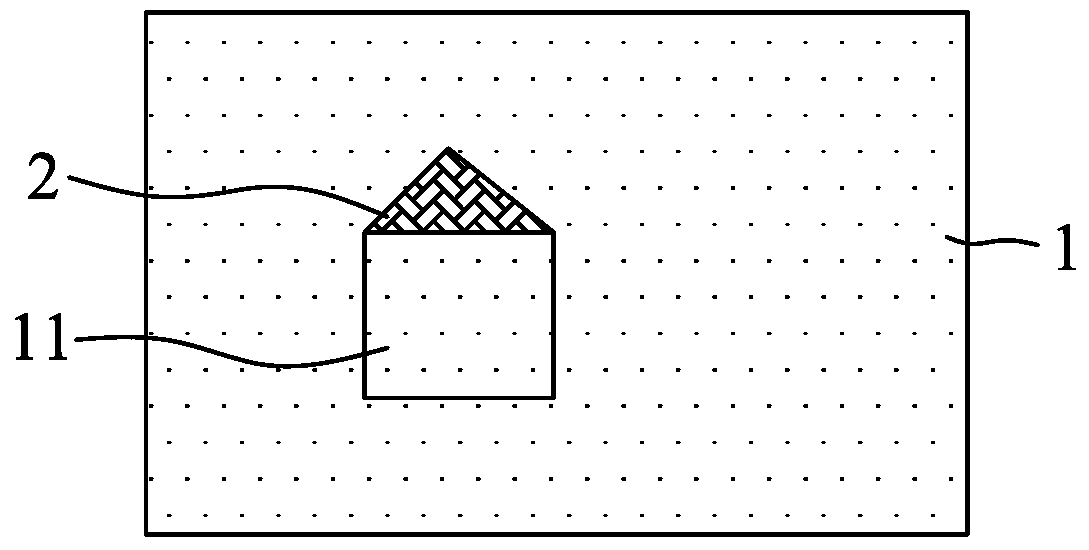

[0028] S1. Carry out perforation processing on the decorative layer, and form a through hole penetrating through the decorative layer on the decorative layer;

[0029] S2. Place the decorative layer on the surface of the fiber cloth pre-impregnated with pre-impregnated resin, and perform hot pressing, so that the pre-impregnated resin attached to the fiber cloth passes through the through hole, penetrates to the surface of the decorative layer and solidifies .

[0030] According to the present invention, first, a decorative layer having a desired decorative pattern is provided. As mentioned above, the decorative layer can specifically adopt an IMD (In-Mold Decoration Technology) decorative layer. In the present invention, there is no limitation on the pattern on the decorative layer. In order to facilitate the...

Embodiment 1

[0043] This embodiment is used to illustrate the casing disclosed in the present invention and its preparation method.

[0044] Take an IMD film with a thickness of 0.1 mm as the decorative layer. A plurality of evenly distributed through holes are formed on the decoration layer by using a mechanical drilling method, the diameter of the through holes is 0.2 mm, and the gap between the through holes is 0.4 mm.

[0045] Carry out sealing agent and release agent pretreatment on the mold.

[0046] After half an hour of pre-treatment, the carbon fiber cloth pre-impregnated with epoxy resin and the above-mentioned decorative layer that has been punched are laid out in sequence in the mold.

[0047] Close the mold and heat and press the mold, and heat and press the prepreg carbon fiber cloth and the decorative layer. The specific method of hot pressing treatment is: hot pressing at 200°C and 2MPa pressure for 10 minutes.

[0048] Open the mold and take out the product to obtain the ...

Embodiment 2

[0051] This embodiment is used to illustrate the casing disclosed in the present invention and its preparation method.

[0052] Take an IMD film with a thickness of 0.4mm as the decorative layer. A plurality of evenly distributed through holes are formed on the decoration layer by a mechanical drilling method, the diameter of the through holes is 1 mm, and the gap between the through holes is 0.3 mm.

[0053] Carry out sealing agent and release agent pretreatment on the mold.

[0054] After half an hour of pretreatment, the aramid fiber cloth pre-impregnated with polyimide and the above-mentioned perforated decorative layer are sequentially laid out in the mold.

[0055] Close the mold and heat and press the mold, and heat and press the pre-impregnated aramid fiber cloth and the decorative layer. The specific method of hot pressing treatment is: hot pressing at 300°C and 5 MPa pressure for 10 minutes.

[0056] Open the mold and take out the product to obtain the required sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com