Energy-saving emission-reducing fully-synthetic infinitely variable transmission driving liquid and preparation method thereof

A continuously variable transmission, energy-saving and emission-reducing technology, applied in lubricating compositions, petroleum industry, etc., to achieve the effects of clean and ash-free dispersion, excellent ultra-low temperature unlimited start-up, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing energy-saving and emission-reducing full-synthetic continuously variable transmission transmission fluid, comprising the following steps:

[0034] 1) Under the catalytic polymerization of toluene, alkylbenzene and polymer binary ethylene propylene hydrocarbon are stirred and reacted at 80-110°C for 2-4 hours to obtain base oil;

[0035] 2) Stir molybdenum anti-wear energy-saving agent and dispersant at 40-60°C for 1-2 hours, then add boronated ashless dispersant, anti-oxidation and anti-corrosion agent, anti-oxidation and anti-wear agent and detergent at 40-60°C Stir at 60°C for 1 to 2 hours to obtain a composite additive;

[0036] 3) Stir the base oil obtained in step 1 and the composite additive obtained in step 2 at 30-50°C for 1-2 hours, and perform coarse and fine filtration to obtain energy-saving and emission-reducing full-synthetic continuously variable transmission transmission fluid.

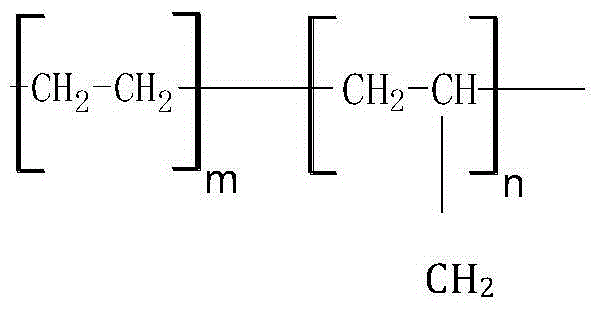

[0037] Among them, the polymer binary ethylene prop...

Embodiment 1

[0040] The invention provides an energy-saving and emission-reducing full-synthetic transmission fluid for continuously variable transmission, which consists of the following components in parts by weight:

[0041] 80 parts of alkyl benzene, 0.7 parts of polymer binary ethylene propylene hydrocarbon, 0.7 parts of toluene, 3.5 parts of detergent, 3.5 parts of dispersant, 0.3 parts of anti-oxidation and anti-corrosion agent, 0.8 parts of anti-oxidation and anti-wear agent, boronized ash-free 12 parts of powder, 0.15 parts of molybdenum anti-wear energy-saving agent.

[0042] Preparation method of fully synthetic continuously variable transmission oil:

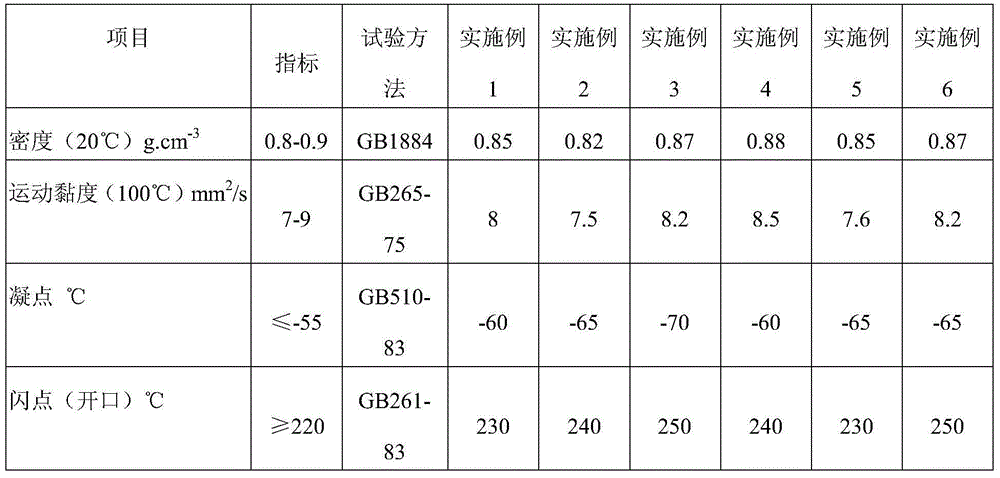

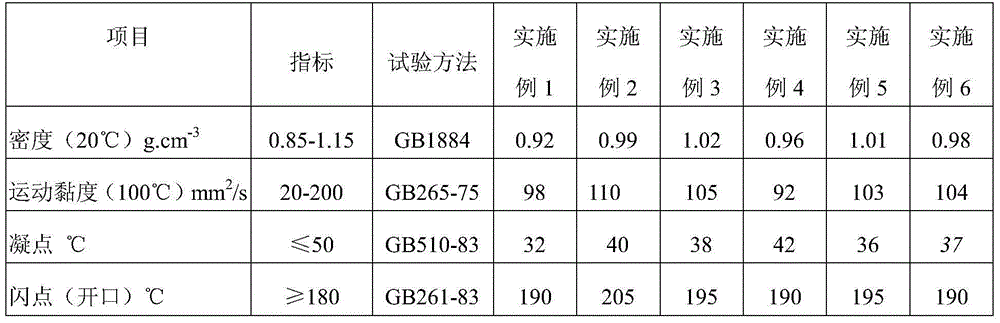

[0043] 1) Mix the high-molecular binary ethylene propylene hydrocarbon with alkylbenzene in an enamel reaction kettle, drop toluene into it with a dropper, and react under toluene catalytic polymerization at 95°C for 3 hours, then vacuum extract the toluene to obtain the base oil; the index detection results of base oil are as s...

Embodiment 2

[0052] The invention provides an energy-saving and emission-reducing full-synthetic transmission fluid for continuously variable transmission, which consists of the following components in parts by weight:

[0053] 75 parts of alkyl benzene, 0.5 part of polymer binary ethylene propylene hydrocarbon, 0.5 part of toluene, 3 parts of detergent, 3 parts of dispersant, 0.1 part of anti-oxidation and anti-corrosion agent, 0.5 part of anti-oxidation and anti-wear agent, boronized ash-free 10 parts of powder, 0.1 part of molybdenum anti-wear energy-saving agent.

[0054] Preparation method of fully synthetic continuously variable transmission oil:

[0055] 1) Mix the high-molecular binary ethylene propylene hydrocarbon with alkylbenzene in an enamel reaction kettle, drop toluene into it with a dropper, under the catalytic polymerization of toluene, stir and react at 110°C for 2 hours, and then vacuum extract the toluene to obtain the base oil; the index detection results of base oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com