Ventilation system for supercharged combustion engines

A technology of a ventilation system and a supercharger, applied in the field of ventilation system, can solve the problems of increasing the pressure difference between the separated oil and the crankcase, and the deterioration of the separated oil return, and achieve the effect of high oil separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

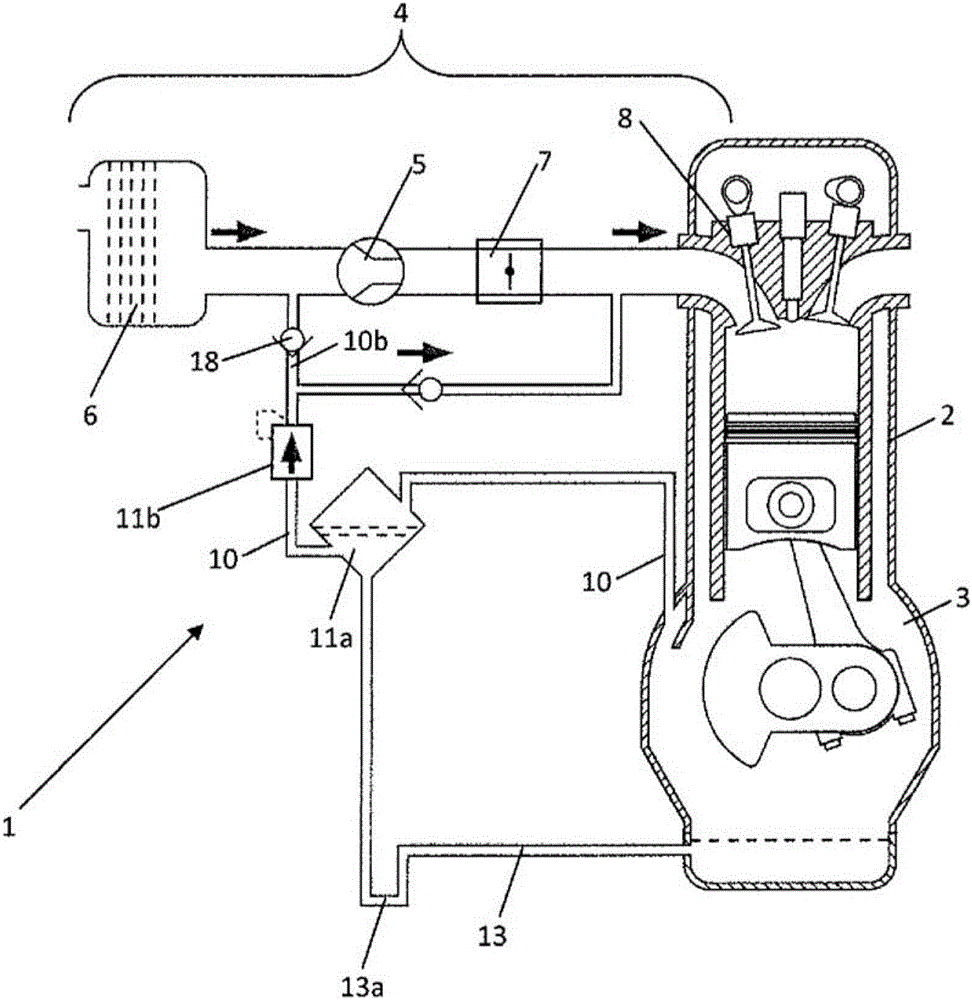

[0042] As already described above, figure 1 An internal combustion engine according to the prior art is shown.

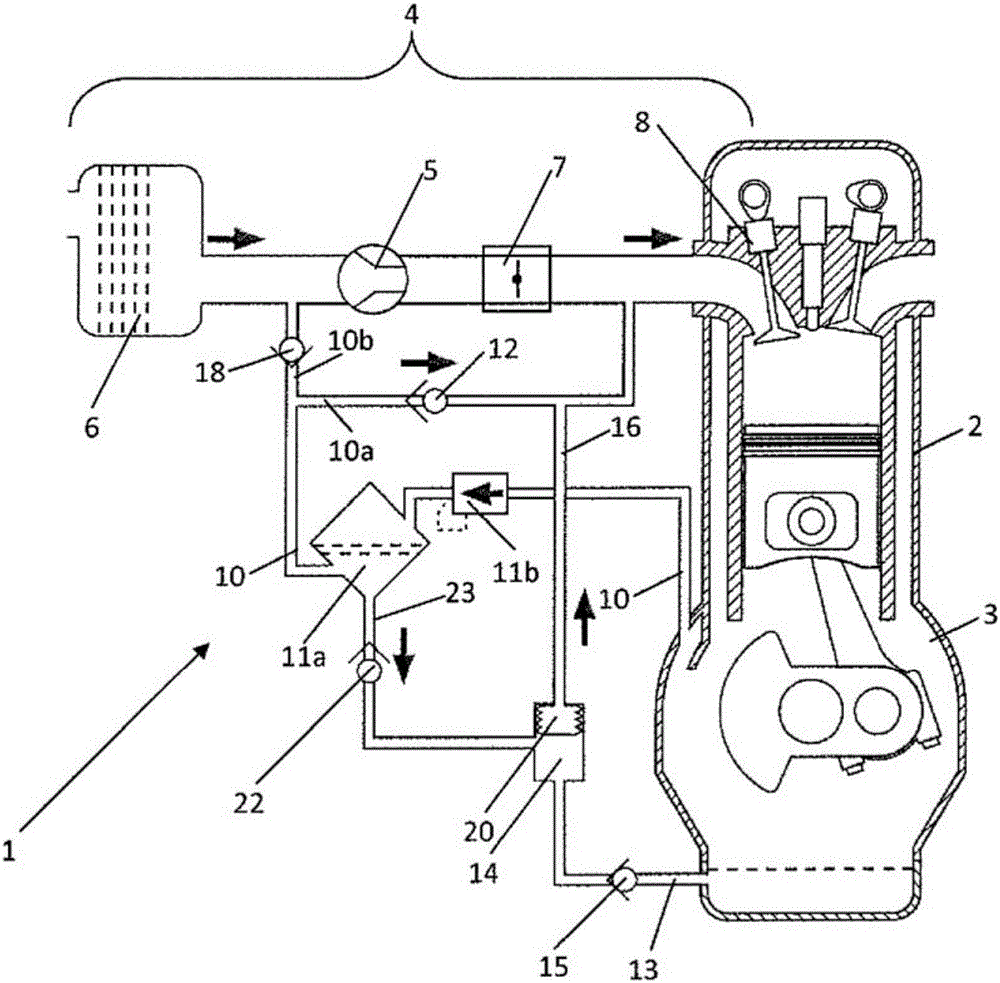

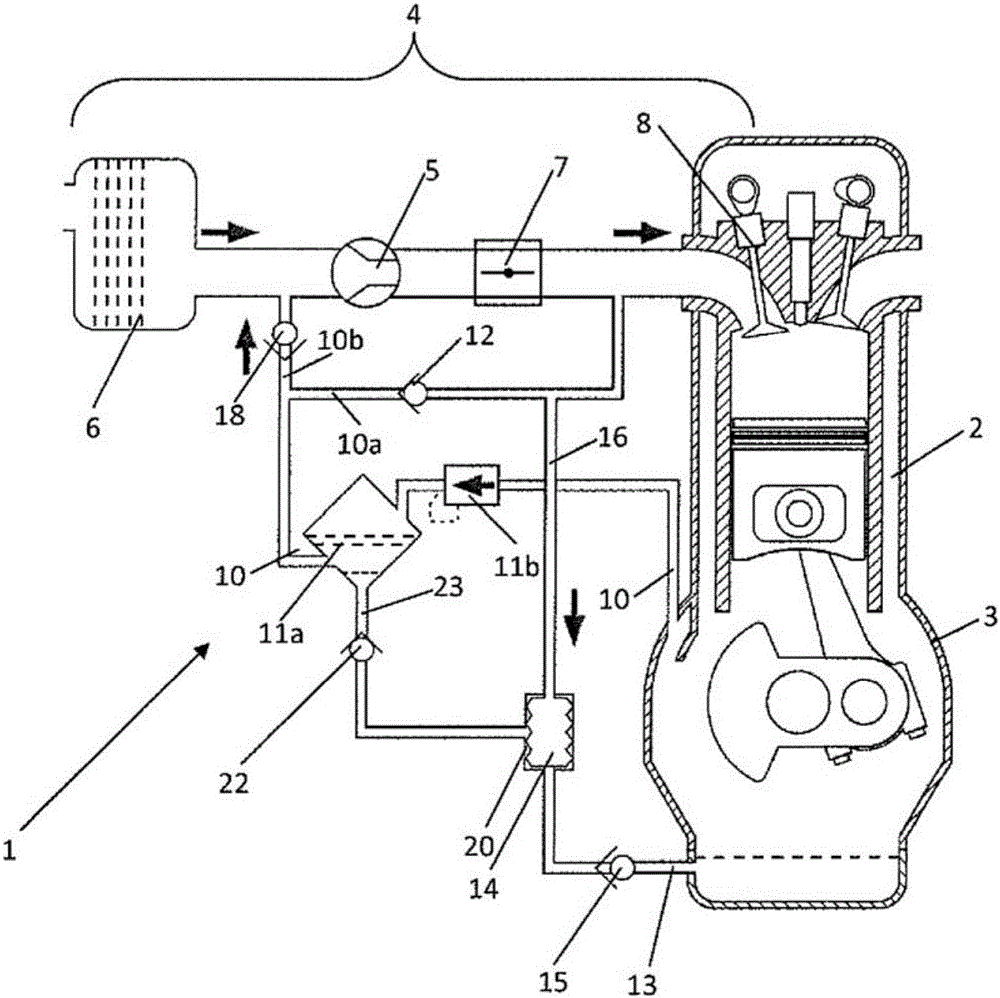

[0043] figure 2 A further internal combustion engine 2 is shown, which has been adapted according to the invention. For this purpose, a bellows is arranged in the tank 14 as the actuating element 20 . The line 23 to the tank 14 also includes a check valve 22 as tank inlet valve, which closes at excess pressure compared to the pressure in the portion 10 e of the vent line 10 . Here, the ventilation line 10 comprises a portion 10a to a portion 10e. Furthermore, in the return line 13 from the tank 14 to the crankcase 3 (via which the separated oil flows back into the crankcase 3 ), a check valve 15 is provided as a tank outlet valve, which check valve 15 closes at a higher pressure in the crankcase relative to the pressure in tank 14 .

[0044] Branching from this ventilation line 10 is a connecting line 16 which, in the present case, operates as a ventilation li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com