A variable manipulator for a fully automatic fire fighting machine

An all-in-one, fully automatic technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of personal safety threats to firefighters, low overall efficiency of fire extinguishing, and reduced fire extinguishing efficiency. Good effect and high fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

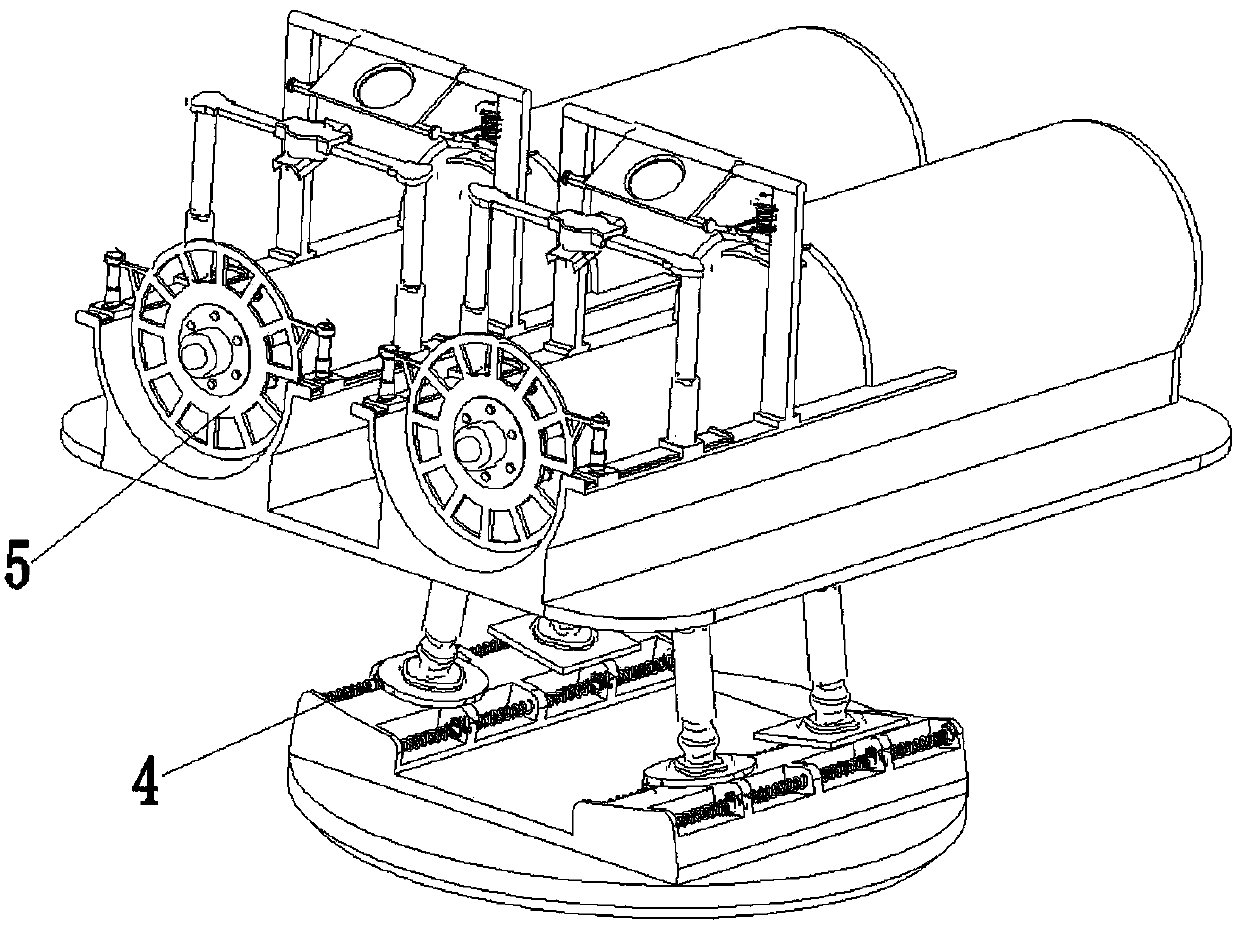

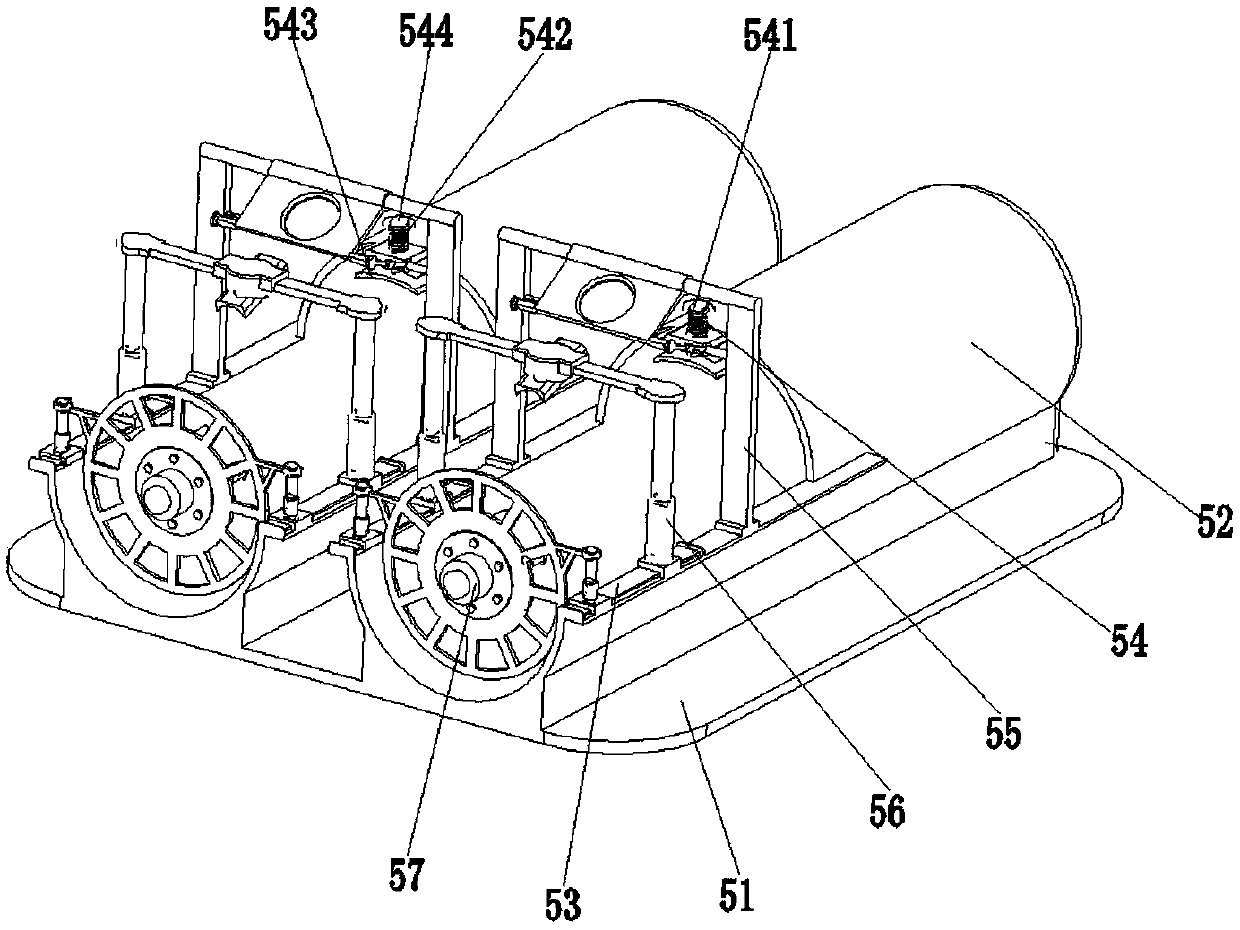

[0027] Such as Figure 1 to Figure 6 As shown, a variable manipulator for a fully automatic fire fighting machine includes a hybrid mechanism 4 and a fire extinguishing device 5; connected.

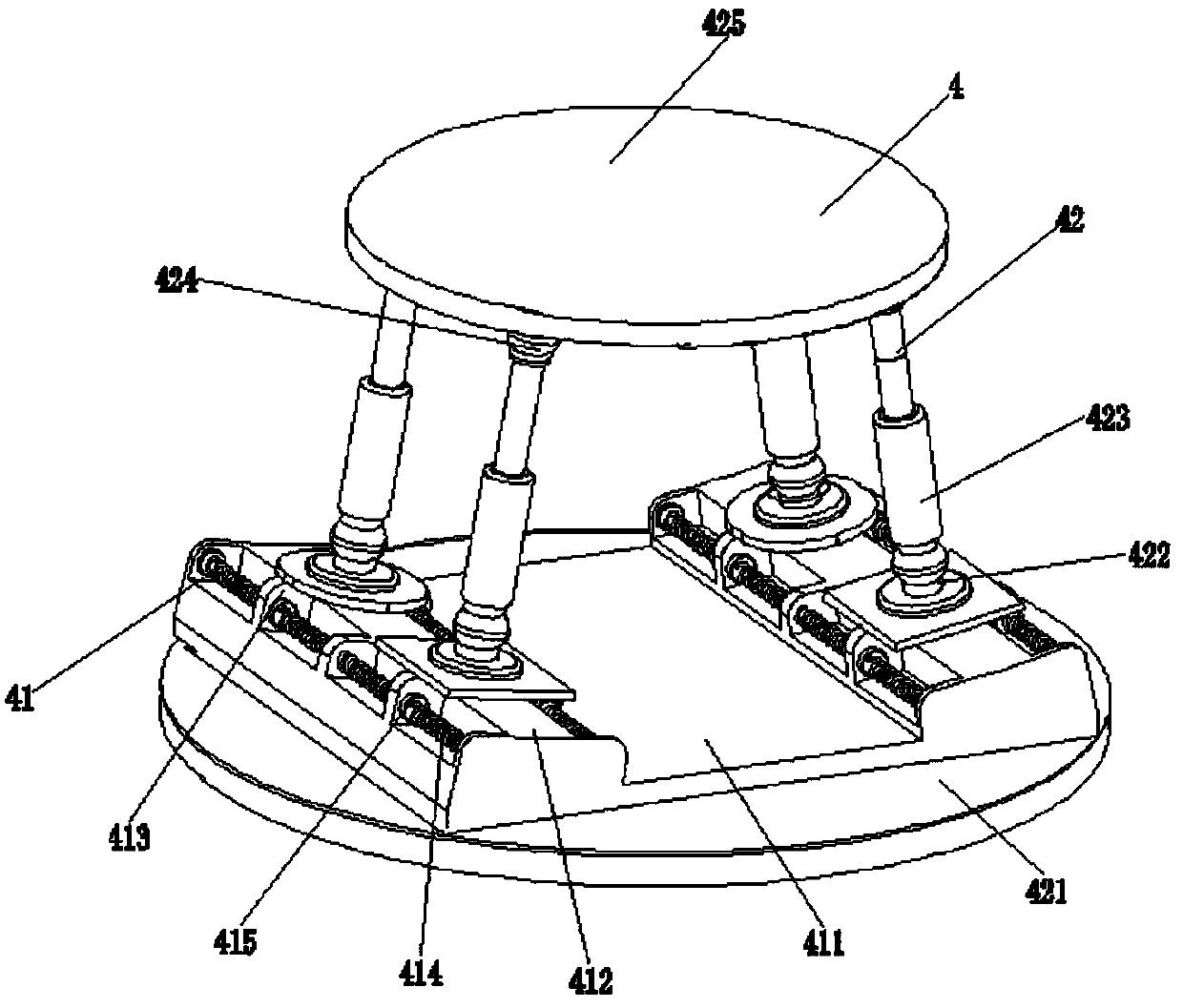

[0028] Such asfigure 1 and figure 2 As shown, the hybrid mechanism 4 includes a mobile chassis 41 and a four-degree-of-freedom parallel mechanism 42, the mobile chassis 41 is located below the four-degree-of-freedom parallel mechanism 42, and the mobile chassis 41 is fixedly connected to the four-degree-of-freedom parallel mechanism 42 The mobile chassis 41 includes a base plate 411, a moving slide rail 412, a slider 413, a limit spring 414 and a locking post 415, and the number of the moving slide rail 412 and the slide block 413 is four, and the limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com