A Submerged Nozzle Electromagnetic Swirl Device

A swirl device and immersion technology, applied in the field of immersion nozzle electromagnetic swirl device, can solve problems such as nozzle blockage, achieve the effects of increasing magnetic field strength, improving inertial force, and avoiding frequent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

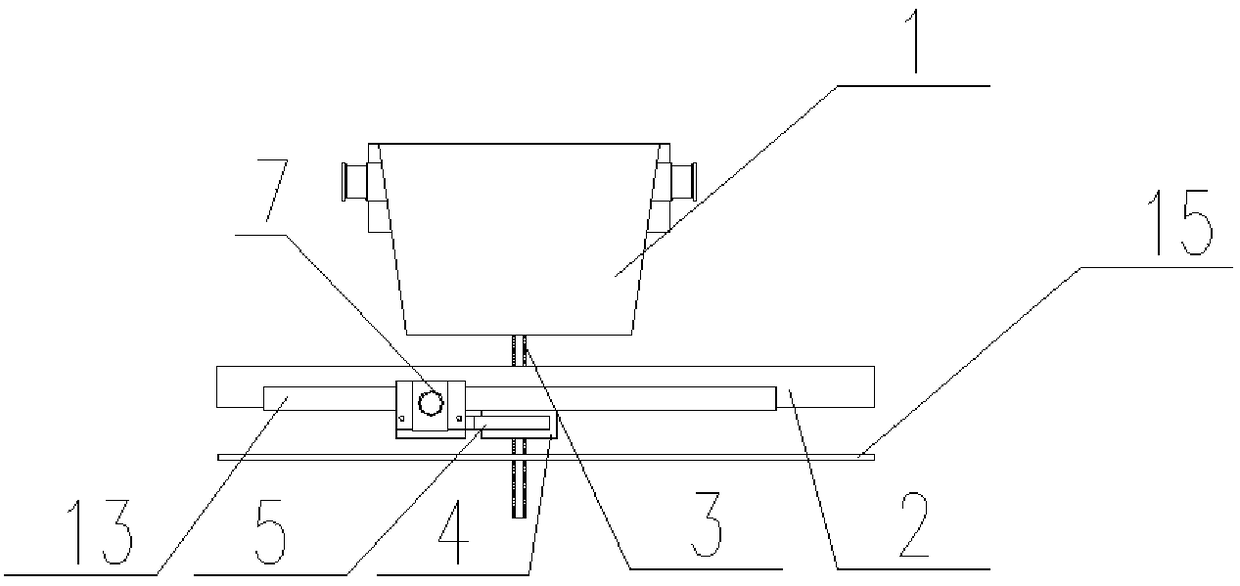

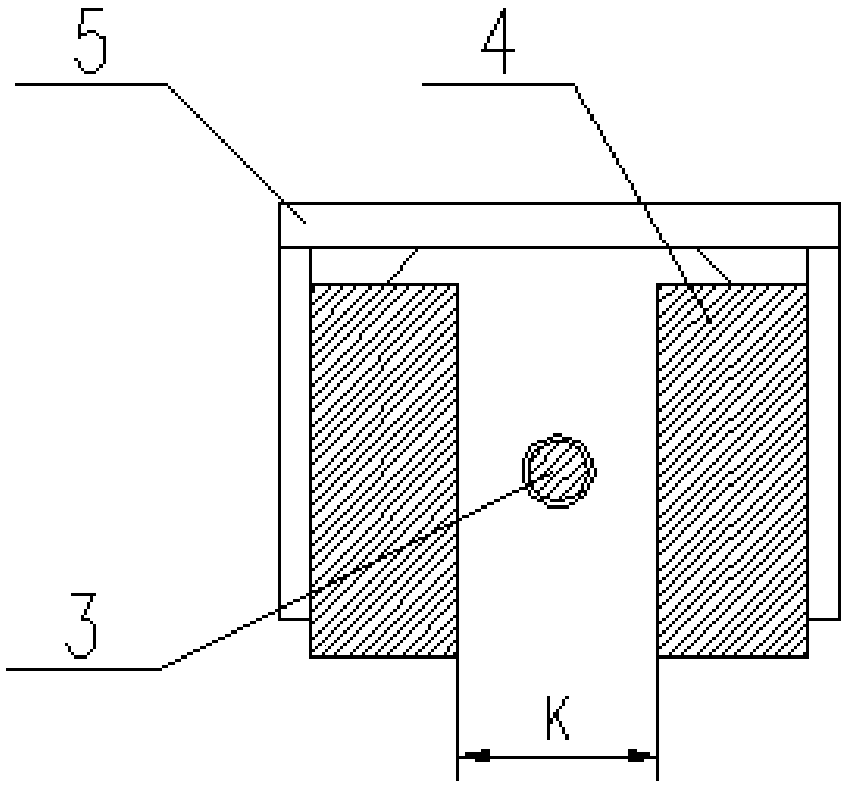

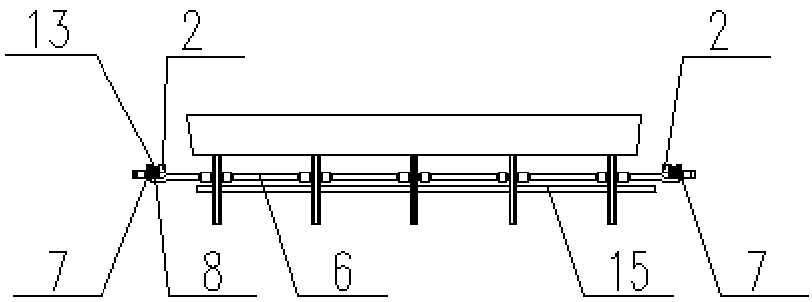

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] Such as Figure 1-4 As shown, in the submerged nozzle electromagnetic swirling device provided by the present invention, several submerged nozzles 3 are installed on the bottom of the tundish 1 along the transverse direction and inserted below the molten steel surface of the crystallizer, and the tube walls of the submerged nozzles 3 The thickness is 10-20mm thicker than that of the pipe wall without electromagnetic stirring device under the same conditions, and the inner diameter is increased by 5-10mm to reach 30-40mm. There are symmetrically installed on both sides of each submerged nozzle 3 along the transverse direction of the tundish 1 Two electromagnetic force generating devices 4 with a distance of 400mm≥K≥230mm, the electromagnetic force generating devices 4 are located on the mold cover plate 15, and the distance betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com