Fermentation preparation method of modified liquid-state local-flavor edible vinegar

A liquid method and flavor technology, which is applied in the field of fermentation preparation of improved liquid-flavored vinegar, can solve the problems of sour taste stimulation, no special flavor, and failure to meet consumers' needs for vinegar taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Prepare the processed whole wheat flour with 22% of the mass of the whole wheat flour, add water to adjust the slurry, add 12U / g whole wheat flour α-high temperature amylase, raise the temperature to 90°C and maintain it for 1h, boil and cool down to 35°C for use.

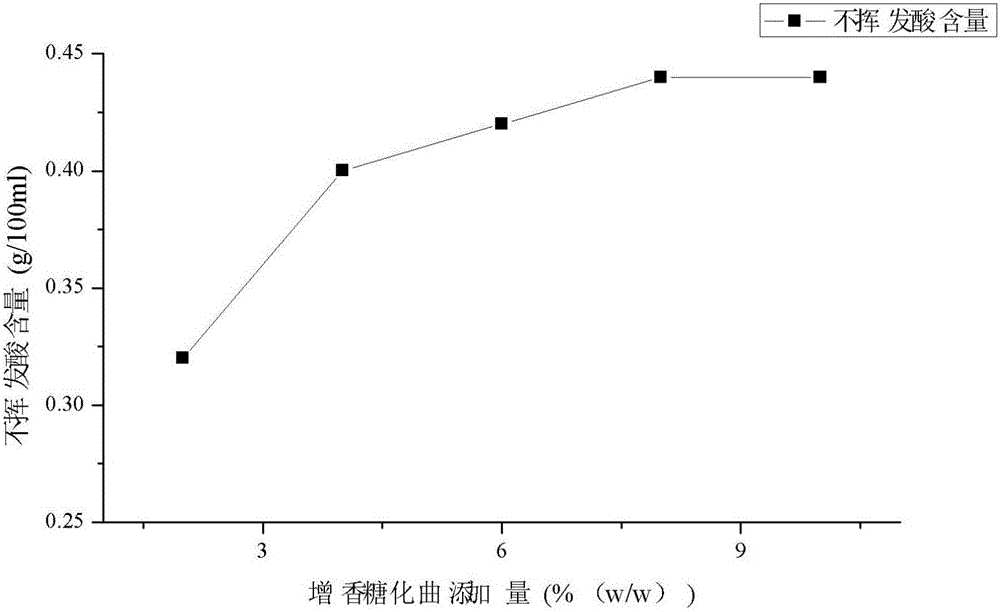

[0025] (2) Add 2%, 4%, 6%, 8%, and 10% flavored mash koji to the liquefied mash, keep the temperature at 35°C for 1 hour, then cool down to 30°C for use.

[0026] (3) Alcoholic fermentation: each mash was inoculated with 5% (v / v) lactic acid bacteria and 0.35 g / 100 g of activated yeast at the same time, controlled temperature at 32° C., fermented for 4 days, and set aside.

[0027] (4) Acetic acid fermentation: Take 50ml of liquid in a 500ml shake bottle, add 7.5ml of acetic acid, add 25ml of flavored wine mash, dilute with water to the final liquid volume, and make vinegar fermented mash. Add 5ml of activated acetic acid bacteria, 30°C, shaker speed 180rpm, the fermentation ends when the acidity does no...

Embodiment 2

[0029] (1) Prepare the processed whole wheat flour with 22% of the mass of the whole wheat flour, add water to adjust the slurry, add 12U / g whole wheat flour α-high temperature amylase, raise the temperature to 90°C and maintain it for 1h, boil and cool down to 35°C for use.

[0030] (2) Add aroma-increasing mash koji with a percentage of 3% of the mass of whole wheat flour to the liquefied mash, keep the temperature at 35°C for 1 hour, then cool down to 30°C for use.

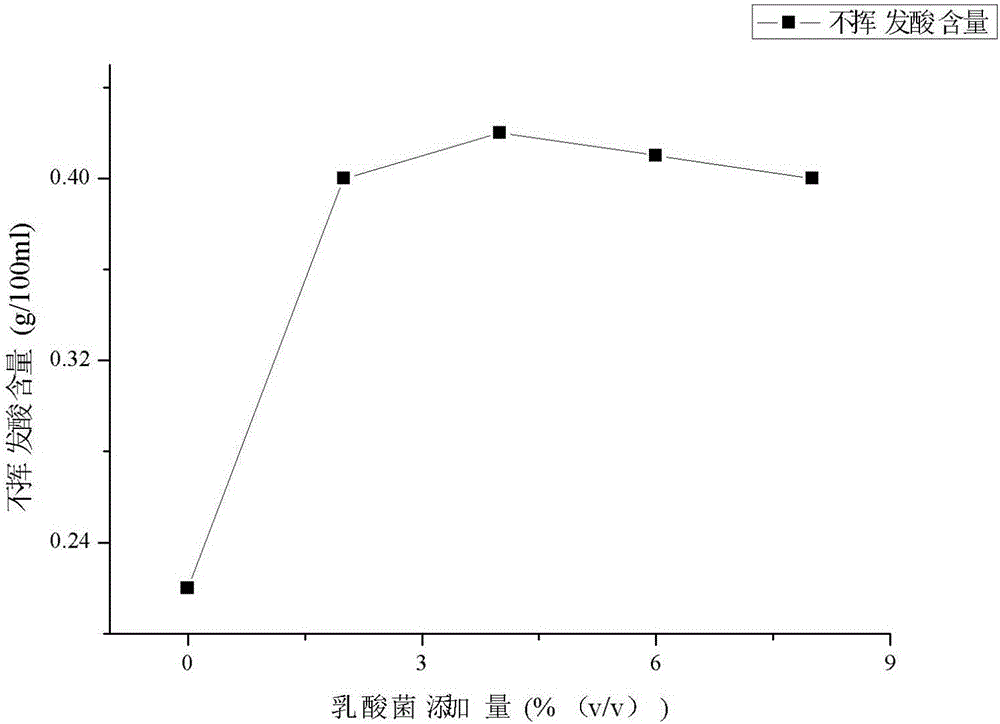

[0031] (3) Alcoholic fermentation: respectively inoculate 0%, 2%, 4%, 6%, 8% (v / v) lactic acid bacteria in the mash, and simultaneously inoculate 0.35g / 100g of activated yeast of the mash, control Temperature 32 ℃, fermentation 4d, stand-by.

[0032] (4) Acetic acid fermentation: Take 50ml of liquid in a 500ml shake bottle, add 7.5ml of acetic acid, add 25ml of flavored wine mash, dilute with water to the final liquid volume, and make vinegar fermented mash. Add 5ml of activated acetic acid bacteria, 30°C, sha...

Embodiment 3

[0034] (1) Prepare the processed whole wheat flour with 22% of the mass of the whole wheat flour, add water to adjust the slurry, add 12U / g whole wheat flour α-high temperature amylase, raise the temperature to 90°C and maintain it for 1h, boil and cool down to 35°C for use.

[0035] (2) Add flavor-increasing saccharified koji with a percentage of 3% of the mass of whole wheat flour in the liquefied mash, keep the temperature at 35°C for 1 hour, and cool down to 30°C for use.

[0036] (3) Alcoholic fermentation: Inoculate 5% (v / v) lactic acid bacteria and 0.35g / 100g activated yeast in the mash respectively, control the temperature at 32°C, ferment for 4 days, and set aside.

[0037] (4) Acetic acid fermentation:

[0038] a. Add 105ml of acetic acid into a 5L self-priming glass tank, then add 1200ml of flavored wine mash, dilute with water to 3L, mix the acidity to 3.50g / 100ml, alcohol content to 3.52%.

[0039] b. Automatically control the temperature of the fermenter to 30°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com