Tapered roller type protective bearing device that simultaneously eliminates the radial and axial clearance of the rotor

A technology for protecting bearings and tapered rollers, applied in the directions of shafts and bearings, rolling contact bearings, bearing components, etc., can solve the problem of complex structure, can not eliminate the axial clearance, can not completely eliminate the radial and axial clearance of the rotor at the same time to protect the bearing equipment, etc., to improve reliability and safety, eliminate vibration and shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

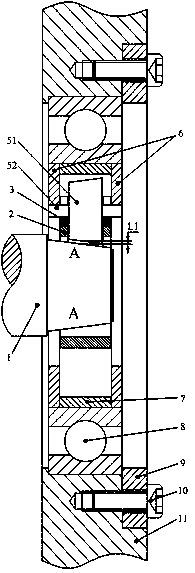

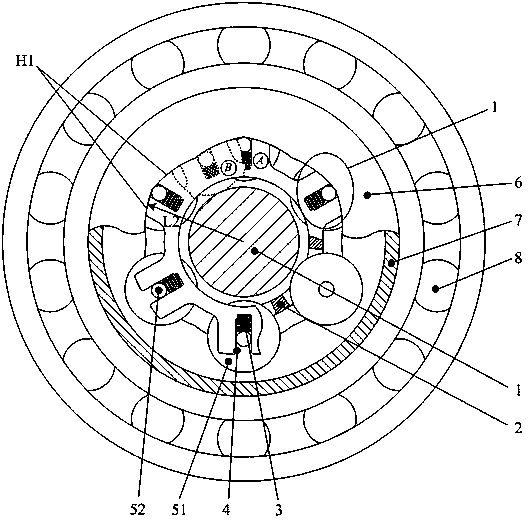

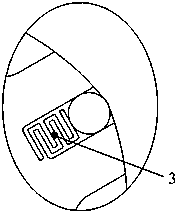

[0026] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] like Figure 1 to Figure 3 As shown, a tapered roller type protective bearing device that eliminates the radial and axial clearance of the rotor at the same time includes a rotor 1, a radial protective bearing, a bearing cover 9, a screw 10 and a bearing seat 11, and the bearing cover 9 connects with the screw 10. The bearing seat 11 is fixedly connected, axially compresses the radial protection bearing, and the bearing seat 11 is fixedly connected with an external machine base. Specifically, the bearing gland 9 is disc-shaped, and the bearing gland 9 is pressed against the joint between the bearing seat 11 and the rolling bearing 9 .

[0028] The radial protection bearing includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com