Variable speed drive and method for machining a variable speed drive

A technology of variable speed drive and drive device, which is applied to electromechanical devices, electric components, electrical components, etc., can solve the problems of increased operating noise, roundness deviation, and variation of the armature shaft, and achieve the effect of reducing friction loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

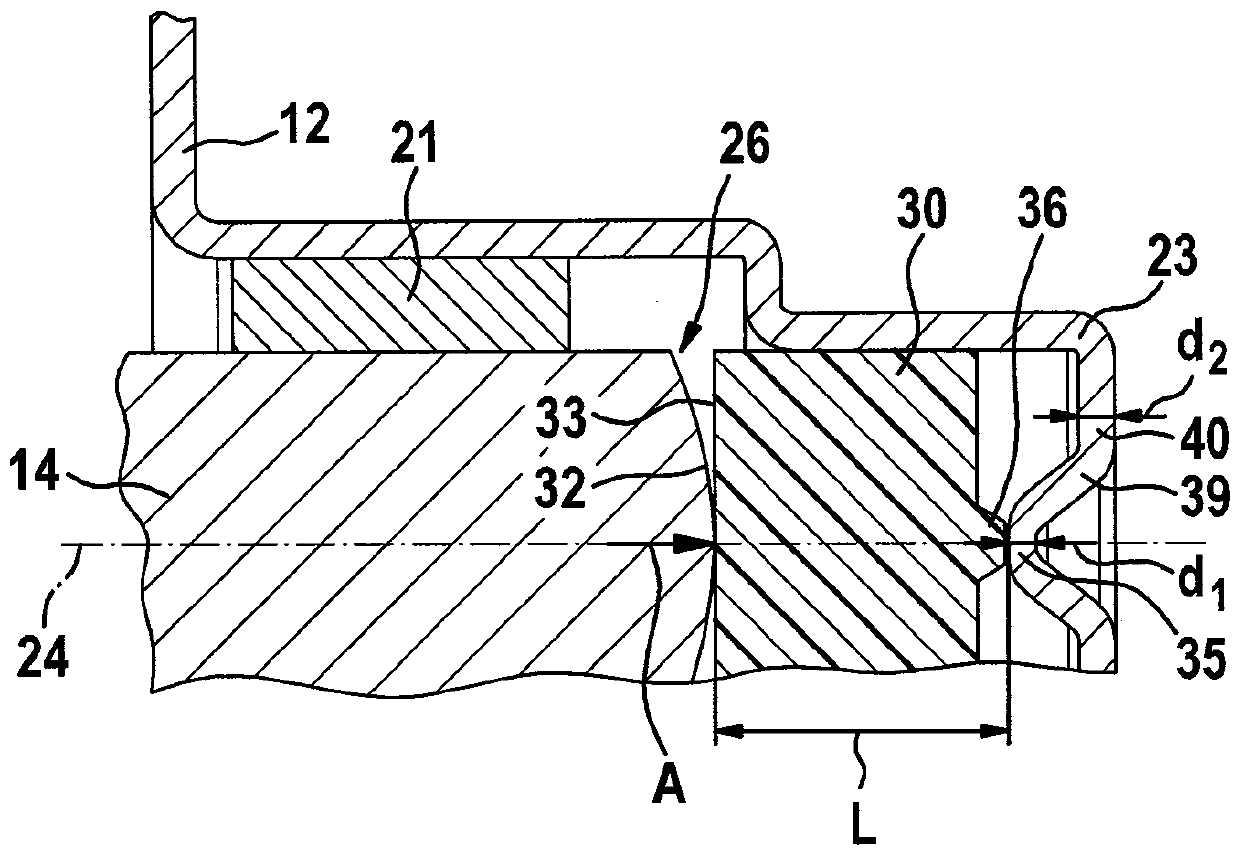

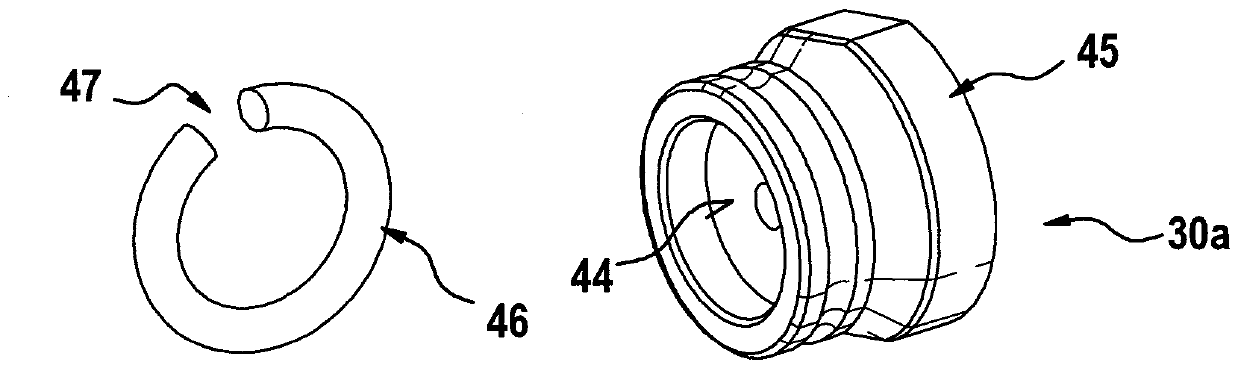

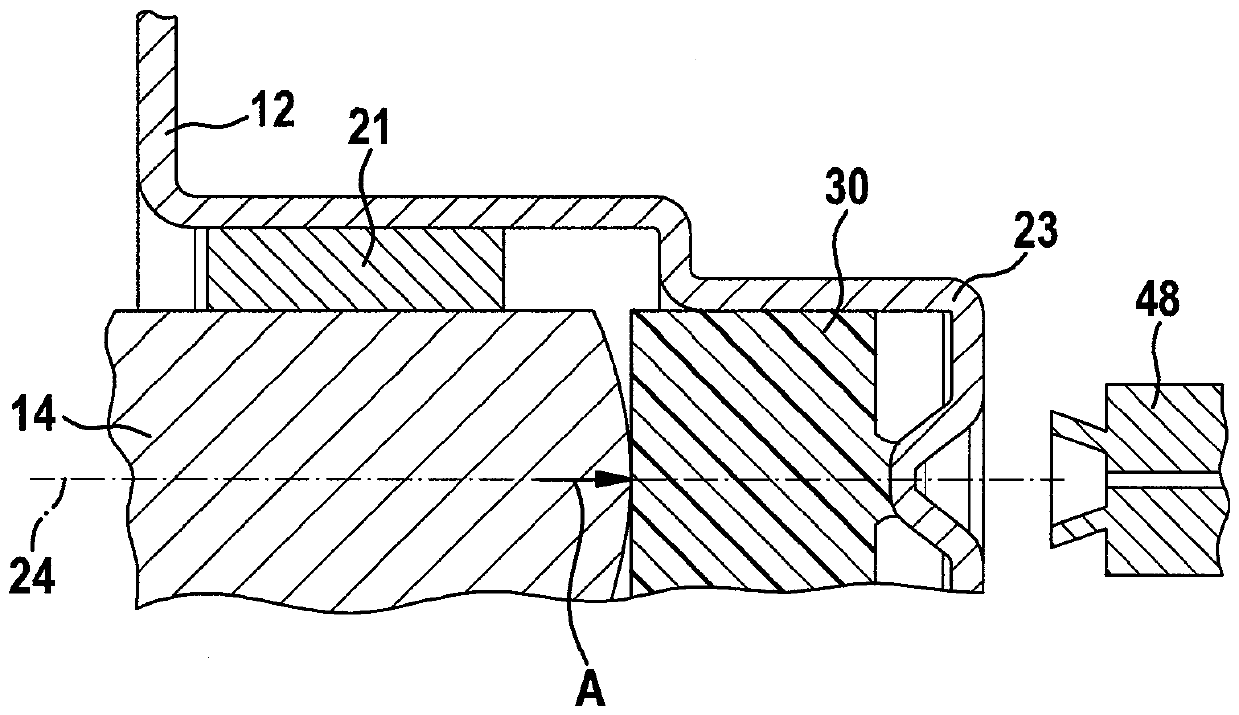

[0029] exist figure 1 A variable speed drive 10 is shown, which is used, for example, as part of a convenience drive in a motor vehicle. A convenience drive is to be understood within the scope of the present invention as a seat adjustment drive, a window lift drive, a sliding roof drive or the like, by way of example and without limitation. This convenient drive is characterized in that the element to be adjusted, for example a glass window, a sliding roof, can be moved in different directions.

[0030] The variable-speed drive 10 includes an electric motor 11 which is arranged as a motor 11 with carbon brushes in a pole housing 12 made of metal. The armature shaft 14 of the electric motor 11 , which partially protrudes from the pole housing 12 , protrudes into a transmission housing 15 , which is generally at least two-part and partially made of metal. In order to fasten the electric motor 11 or the pole housing 12 on the transmission housing 15 , the pole housing 12 is sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com