Active anti-blockage mechanism body

An active, single-body technology, applied in planting methods, agricultural machinery and implements, shovels, etc., can solve the problems of poor anti-blocking performance and weak passing performance of implements, achieve strong anti-blocking performance, improve work efficiency, and soil disturbance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

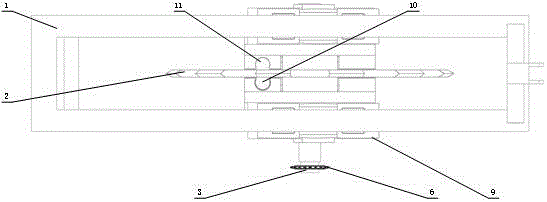

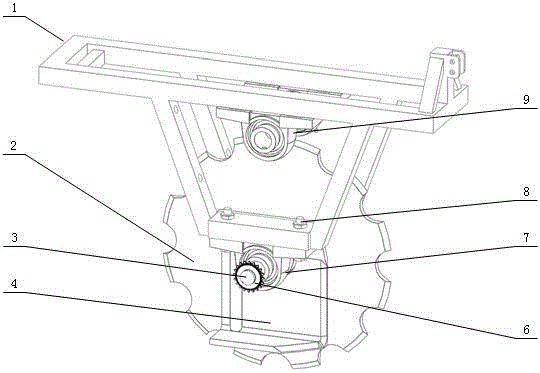

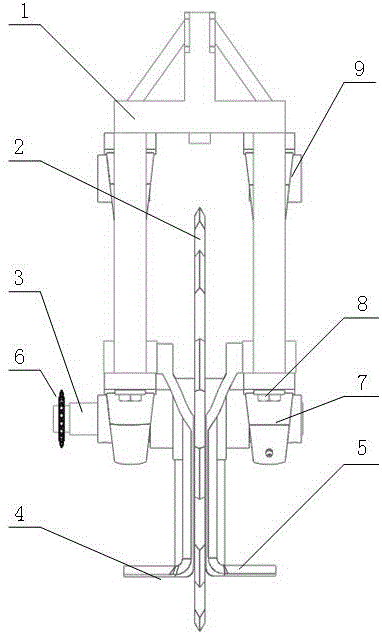

[0022] Embodiment 1: as Figure 1-3 As shown, a single active anti-blocking mechanism includes a frame assembly, an anti-blocking ditching assembly, a fertilization and seeding joint assembly and a transmission assembly, wherein the anti-blocking ditching assembly, the fertilization and seeding joint assembly and the The transmission assembly is fixedly installed on the frame assembly;

[0023] The anti-blocking ditching assembly includes a stubble cutting cutter 2, an L-shaped knife I4 and an L-shaped knife II5; wherein the stubble cutting cutter 2 is installed on the drive shaft 3 of the transmission assembly, and the L-shaped knife I4 and the L-shaped knife Ⅱ5 is close to the left and right sides of the stubble cutting cutter head 2;

[0024] The transmission assembly includes a drive shaft 3 and a drive sprocket 6; wherein the drive sprocket 6 is installed on the outer end of one side of the drive shaft 3, and receives the input of torque through the chain transmission to...

Embodiment 2

[0028] Embodiment 2: as Figure 1-3 As shown, a single active anti-blocking mechanism includes a frame assembly, an anti-blocking ditching assembly, a fertilization and seeding joint assembly and a transmission assembly, wherein the anti-blocking ditching assembly, the fertilization and seeding joint assembly and the The transmission assembly is fixedly installed on the frame assembly;

[0029] The anti-blocking ditching assembly includes a stubble cutting cutter 2, an L-shaped knife I4 and an L-shaped knife II5; wherein the stubble cutting cutter 2 is installed on the drive shaft 3 of the transmission assembly, and the L-shaped knife I4 and the L-shaped knife Ⅱ5 is close to the left and right sides of the stubble cutting cutter head 2;

[0030] The transmission assembly includes a drive shaft 3 and a drive sprocket 6; wherein the drive sprocket 6 is installed on the outer end of one side of the drive shaft 3, and receives the input of torque through the chain transmission to...

Embodiment 3

[0032] Embodiment 3: as Figure 1-3 As shown, a single active anti-blocking mechanism includes a frame assembly, an anti-blocking ditching assembly, a fertilization and seeding joint assembly and a transmission assembly, wherein the anti-blocking ditching assembly, the fertilization and seeding joint assembly and the The transmission assembly is fixedly installed on the frame assembly;

[0033] The anti-blocking ditching assembly includes a stubble cutting cutter 2, an L-shaped knife I4 and an L-shaped knife II5; wherein the stubble cutting cutter 2 is installed on the drive shaft 3 of the transmission assembly, and the L-shaped knife I4 and the L-shaped knife Ⅱ5 is close to the left and right sides of the stubble cutting cutter head 2;

[0034] The transmission assembly includes a drive shaft 3 and a drive sprocket 6; wherein the drive sprocket 6 is installed on the outer end of one side of the drive shaft 3, and receives the input of torque through the chain transmission to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com