Method for making frozen dough through fermented-rice wine

A technology for freezing dough and dough, which is applied in dough processing, dough preparation, dough cooling, etc. It can solve the problems that the raw dough cannot be frozen alone, the gluten network of steamed buns collapses and the yeast cells are easily broken by freezing, etc. , to achieve the effect of improving food processing technology, solving high rent costs and reducing food processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

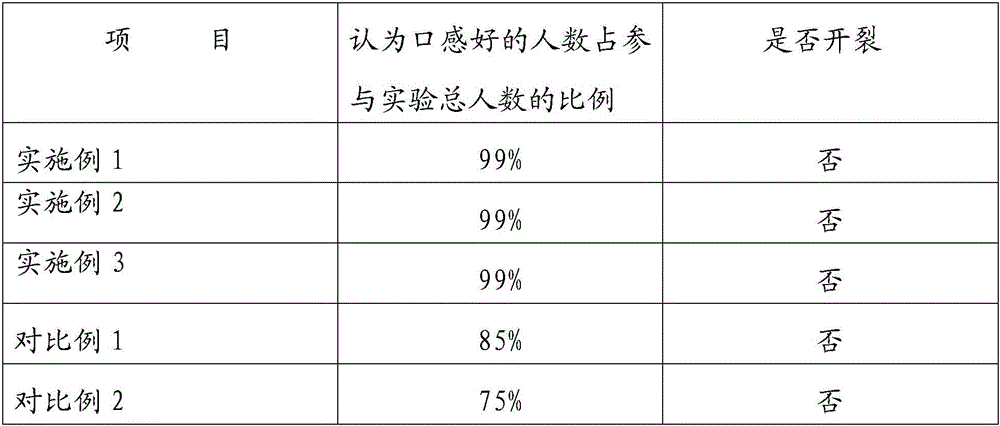

Embodiment 1

[0083] The recipe for making frozen dough with yeast, including yeast dough, flour for secondary docking, edible alkali, yeast and improver. The mass ratio of the yeast dough to the flour for secondary docking is 10%, the mass ratio of the edible alkali to the flour for secondary docking is 0.3%, and the mass ratio of the yeast to the flour for secondary docking is 0.2%. , the mass ratio of the improving agent to the flour for secondary docking is 0.1%. The improving agent is a mixture of enzyme preparation, antifreeze agent and sodium carboxymethyl cellulose. The mass ratio of enzyme preparation, antifreeze agent and sodium carboxymethyl cellulose is 5:2:3.

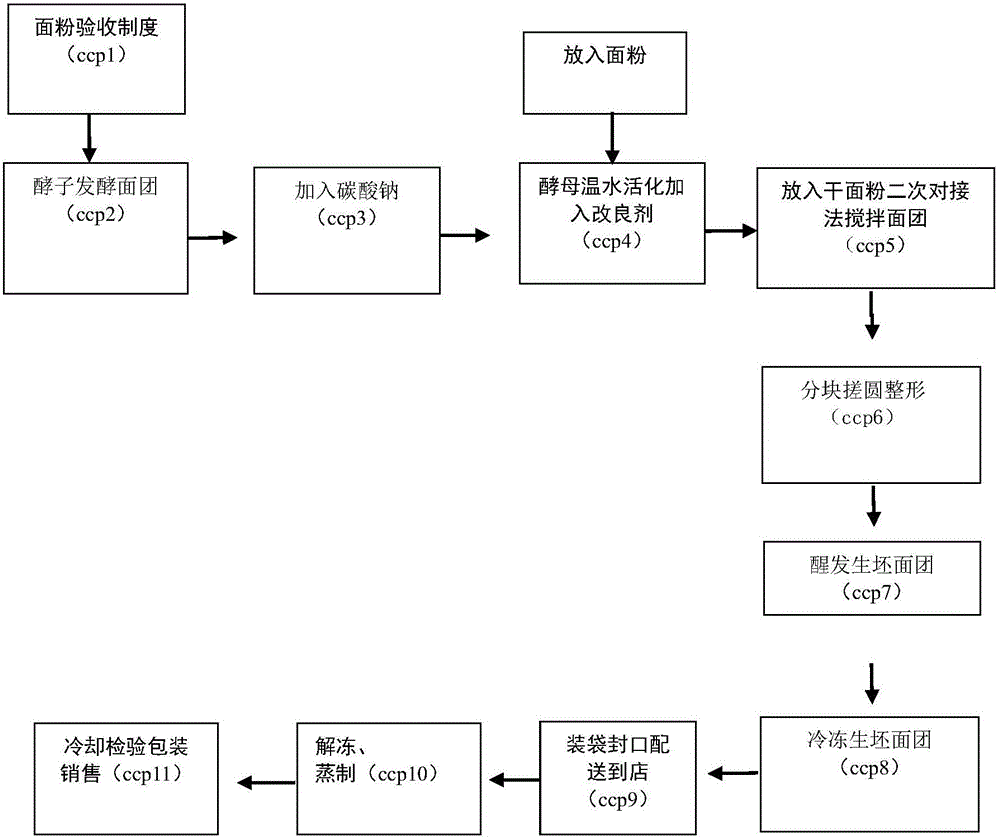

[0084] Such as figure 1 Shown, a kind of preparation method of steamed bread comprises the following steps:

[0085] 1. Acceptance of raw and auxiliary materials (ccp1)

[0086] Strictly follow the instructions for the purchase inspection of raw and auxiliary materials. And implement the company's strict acceptance ...

Embodiment 2

[0108] The recipe for making frozen dough with yeast, including yeast dough, flour for secondary docking, edible alkali, yeast and improver. The mass ratio of the yeast dough to the flour for secondary docking is 30%, the mass ratio of the edible alkali to the flour for secondary docking is 0.7%, and the mass ratio of the yeast to the flour for secondary docking is 0.5%. , the mass ratio of the improving agent to the flour for secondary docking is 0.3%. The improving agent is a mixture of enzyme preparation, antifreeze agent and sodium carboxymethyl cellulose. The mass ratio of enzyme preparation, antifreeze agent and sodium carboxymethyl cellulose is 5:2:3.

[0109] Such as figure 1 Shown, a kind of preparation method of steamed bread comprises the following steps:

[0110] 1. Acceptance of raw and auxiliary materials (ccp1)

[0111] Strictly follow the instructions for the purchase inspection of raw and auxiliary materials. And implement the company's strict acceptance ...

Embodiment 3

[0133] The recipe for making frozen dough with yeast, including yeast dough, flour for secondary docking, edible alkali, yeast and improver. The mass ratio of the yeast dough to the flour for secondary docking is 15%, the mass ratio of the edible alkali to the flour for secondary docking is 0.5%, and the mass ratio of the yeast to the flour for secondary docking is 0.3%. , the mass ratio of the improving agent to the flour for secondary docking is 0.2%. The improving agent is a mixture of enzyme preparation, antifreeze agent and sodium carboxymethyl cellulose. The mass ratio of enzyme preparation, antifreeze agent and sodium carboxymethyl cellulose is 5:2:3.

[0134] Such as figure 1 Shown, a kind of preparation method of steamed bread comprises the following steps:

[0135] 1. Acceptance of raw and auxiliary materials (ccp1)

[0136] Strictly follow the instructions for the purchase inspection of raw and auxiliary materials. And implement the company's strict acceptance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com