Dust bag type dust collector

A technology for vacuum cleaners and dust bags, applied in the directions of vacuum cleaners, suction filters, exhaust diffusion devices, etc., can solve problems such as deficiencies, and achieve the effects of reasonable structure, strong dust collection and separation ability, and good mute effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

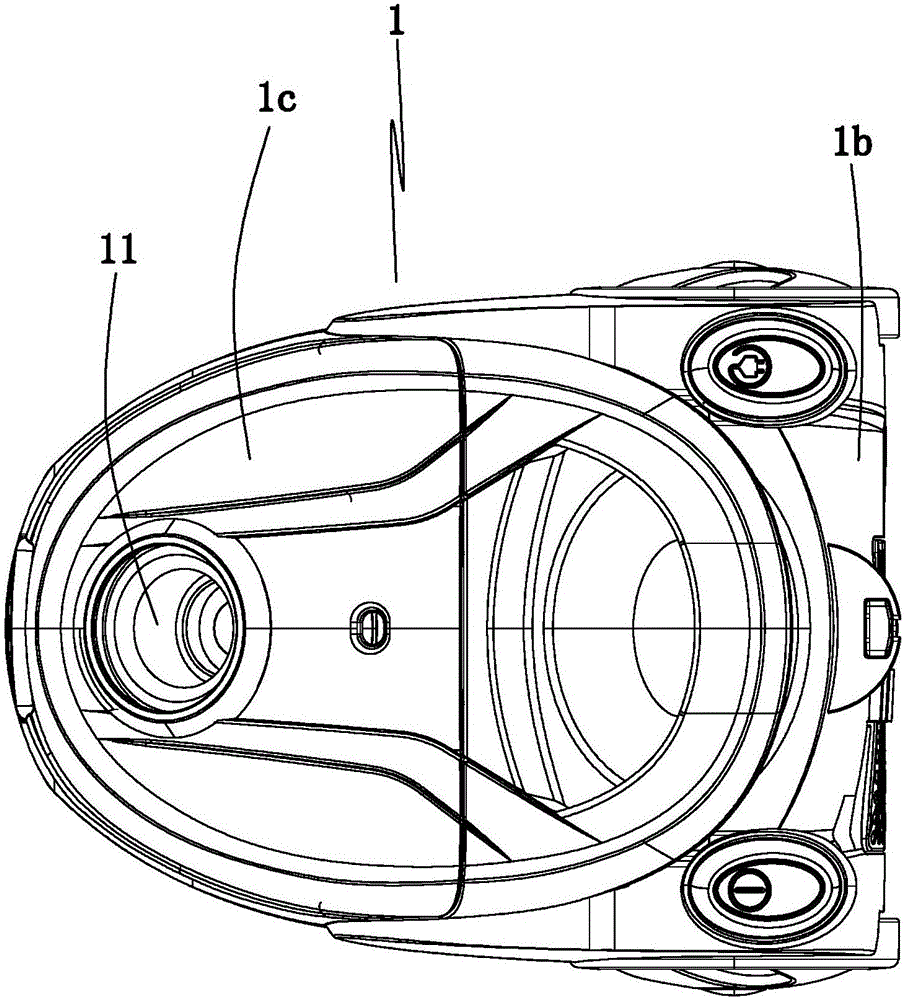

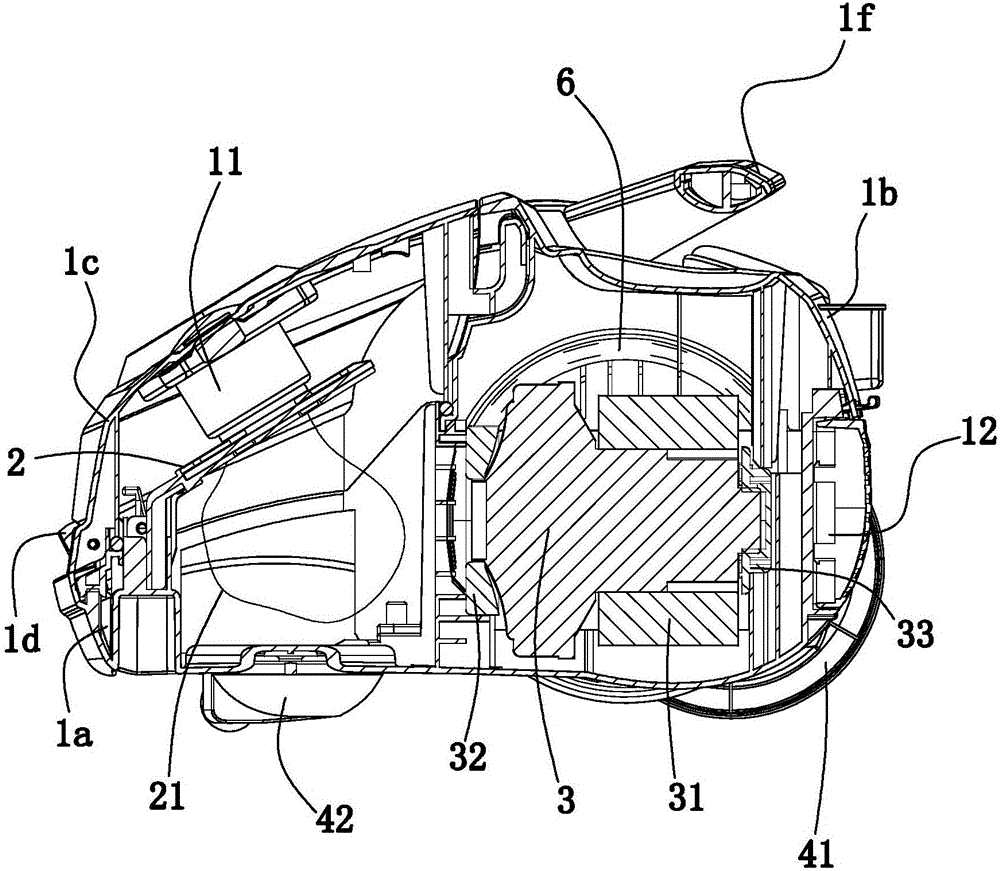

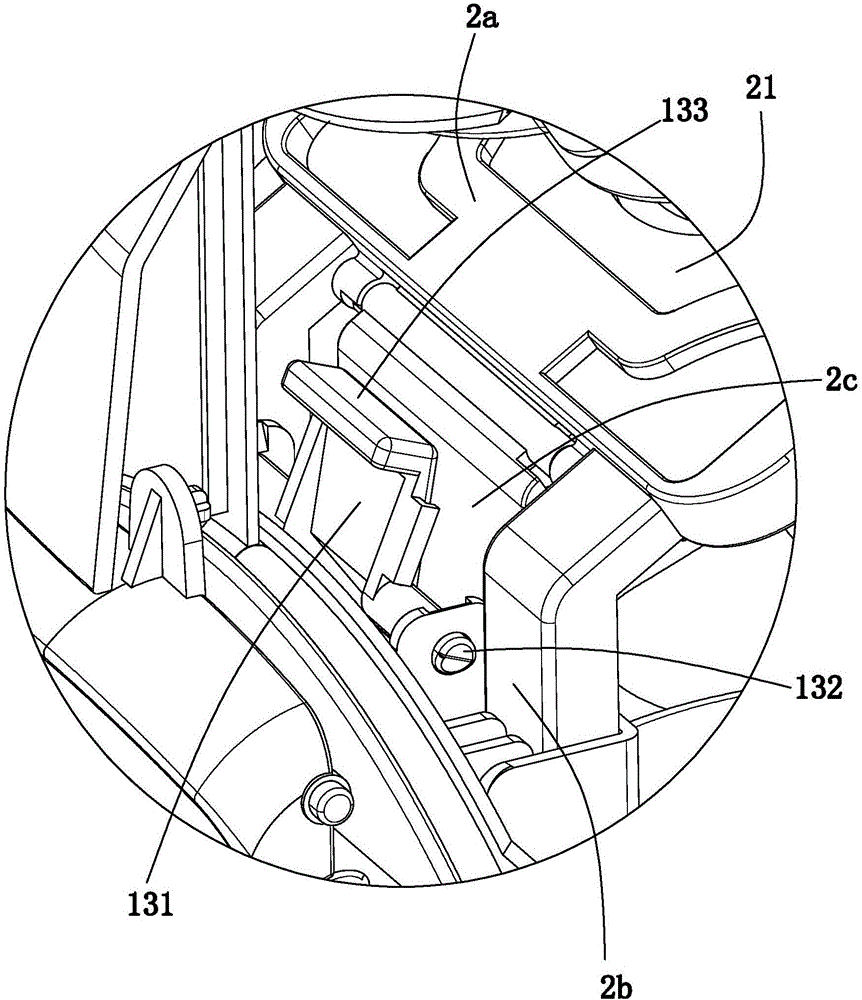

[0028] Example 1: Such as Figure 1 to Figure 6 In the illustrated embodiment, a dust bag vacuum cleaner includes a main body 1 and a power supply device. The main body is provided with a motor cavity and a dust collecting tank. The dust collecting tank is provided with a dust bag 21. The bag holder 2 that clamps the dust bag and the suction mouth seat 11 for docking with the dust suction pipe. The dust bag has an opening, and the opening of the dust bag is connected with the suction mouth seat. A dust suction motor 3 is arranged in the motor cavity. The air inlet is communicated with the dust collecting tank, the air outlet of the dust suction motor is communicated with the air outlet provided on the main body, and a sound-proof sponge 31 contacting the outer surface of the motor is provided in the motor cavity. The dust suction motor is used to provide negative pressure suction, and the dust bag is used for filtering. After the airflow passes through the dust bag, the dust wil...

Embodiment 2

[0037] Example 2: The basic structure and implementation of this example are the same as that of Example 1. The difference is that the power supply device includes a power cord and a cord reel 6 arranged on the host. The power cord is wound on the coil. On the wire.

Embodiment 3

[0038] Embodiment 3: The basic structure and implementation of this embodiment are the same as in Embodiment 1, the difference lies in that Figure 7 to Figure 11 As shown in the figure, the power supply device includes a battery 7. The battery includes a battery casing 71 and a battery pack 711 arranged in the battery casing. The bottom of the battery casing is provided with a main vent communicating with the outside, and the battery casing is provided with several Auxiliary vents connected to the outside world. A shock-absorbing frame 712 is provided in the battery case. The battery pack is connected to the shock-absorbing frame. A number of shock-absorbing springs 7211 are arranged between the shock-absorbing frame and the bottom of the battery case. The lower end of the body is provided with a number of vertically arranged guide posts 721, and the inner bottom of the battery case is provided with a number of guide sleeves 722. The guide posts correspond to the guide sleeves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com