Filter for water curtain sealing mechanism of graphite processing machine tool

A sealing mechanism and a technology for processing machine tools, applied in the field of separation, can solve the problems of limited paper tape filtration accuracy, affecting the accuracy of graphite processed parts, shortening the service life of machine tools, etc., to achieve overall automatic control, prolong machine tool life, and eliminate wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

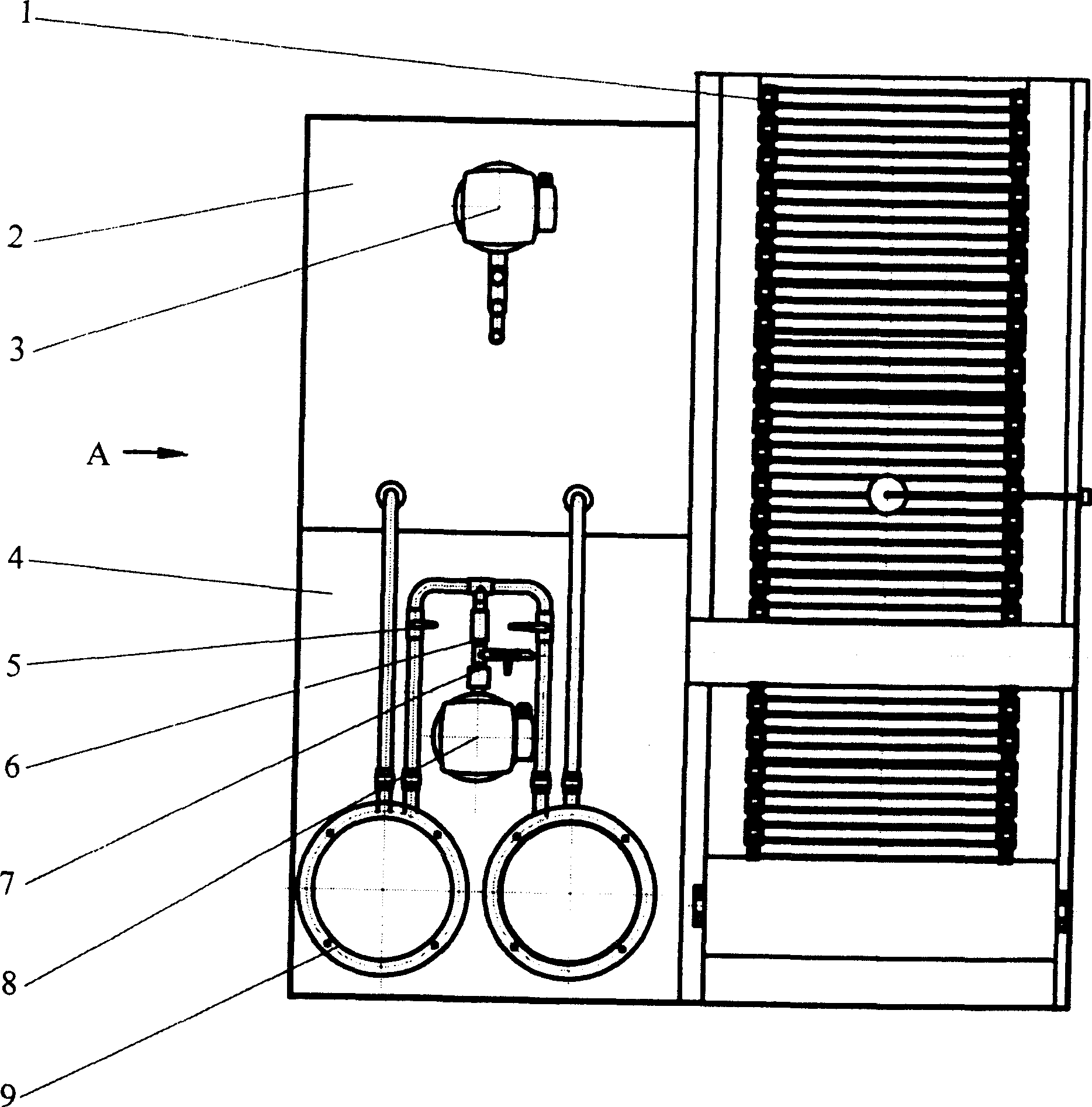

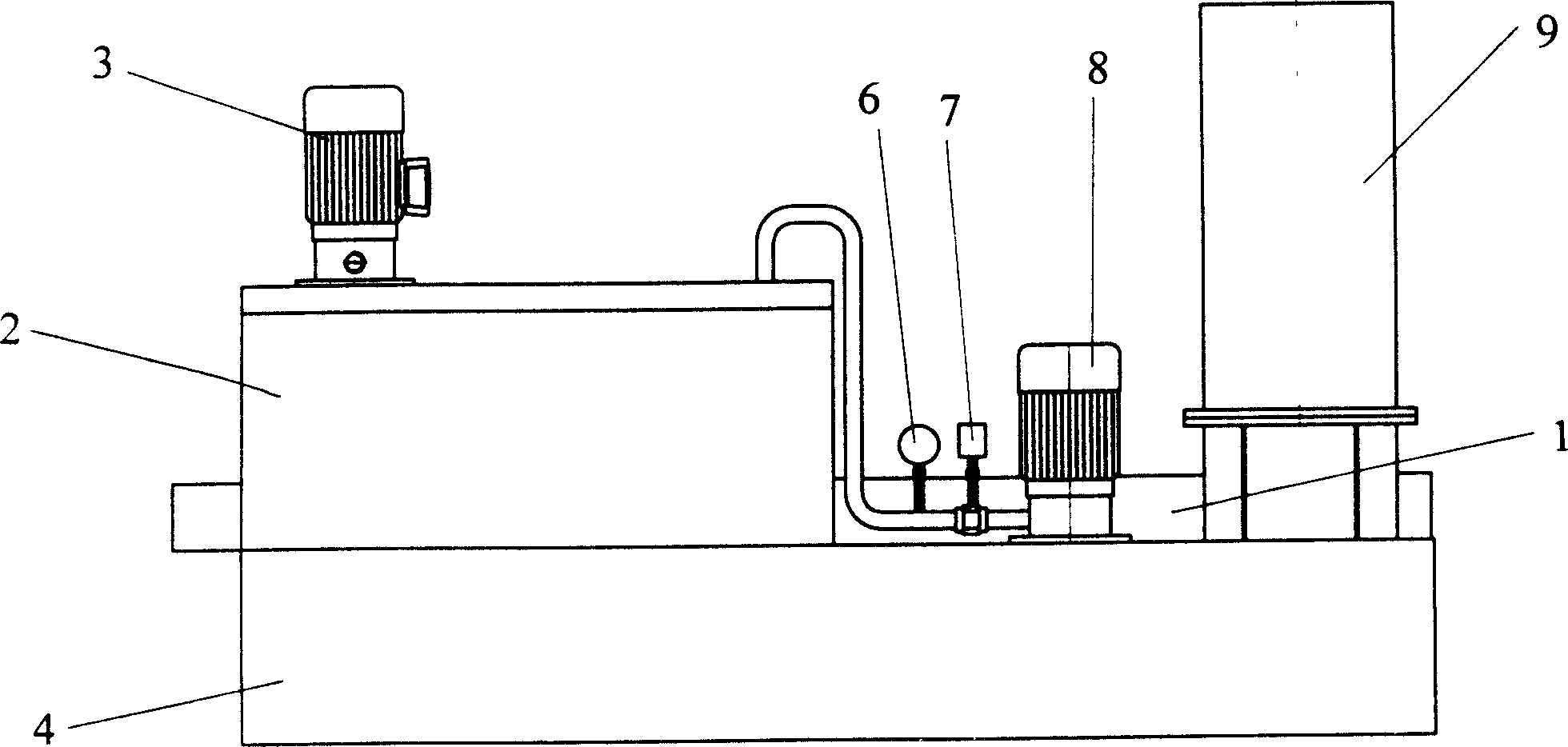

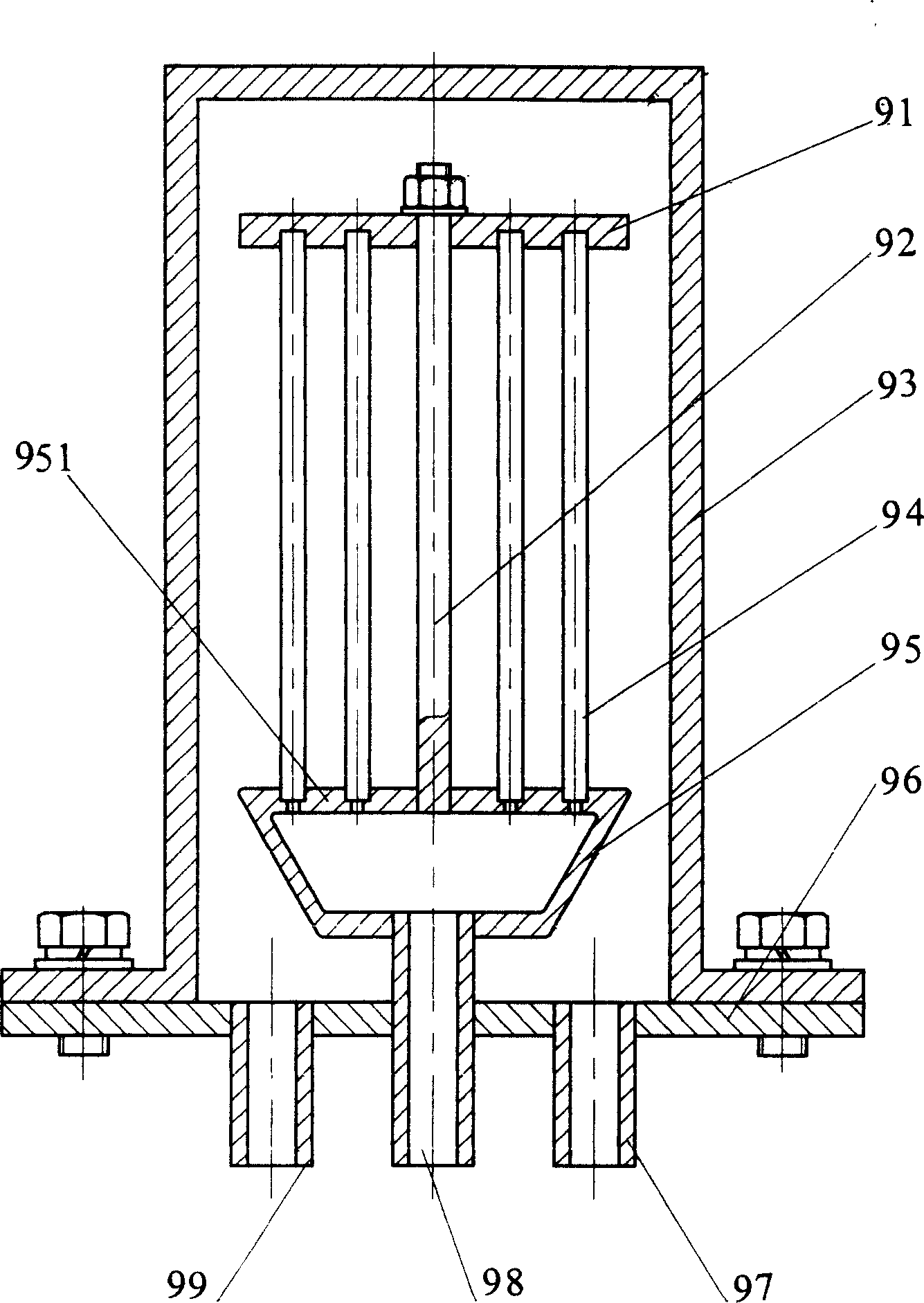

[0018] see figure 1 and figure 2 As shown, the present invention comprises paper tape filter 1, and this paper tape filter 1 has lifting pump, liquid level switch, paper tape conveying motor, paper tape conveying chain belt etc., is the conventional prior art commonly used in existing graphite processing machine tool, This specification will not repeat them. The present invention is provided with soft screw electric pump 8, pressure gauge 6, valve 5 and membrane filter 9 that are connected with paper tape filter 1 outlet, wherein the water inlet of soft screw electric pump 8 is connected with the outlet of paper tape filter 1. The water port is connected, and for the convenience of this connection, a lower water tank 4 can be provided, and the water inlet of the soft screw electric pump 8 and the water outlet of the paper tape filter 1 are jointly placed in the lower water tank 4, so that both can be easily realized. connection between. The water outlet of the soft screw e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com