Micronization device of bamboo and micronization method

A technology of micronization and bamboo, applied in the direction of mechanical equipment, wood processing equipment, sugarcane machining, etc., can solve the problems of non-continuous operation, increase in blade cost, cost increase, etc., and achieve the effect of inhibiting the shortening of life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

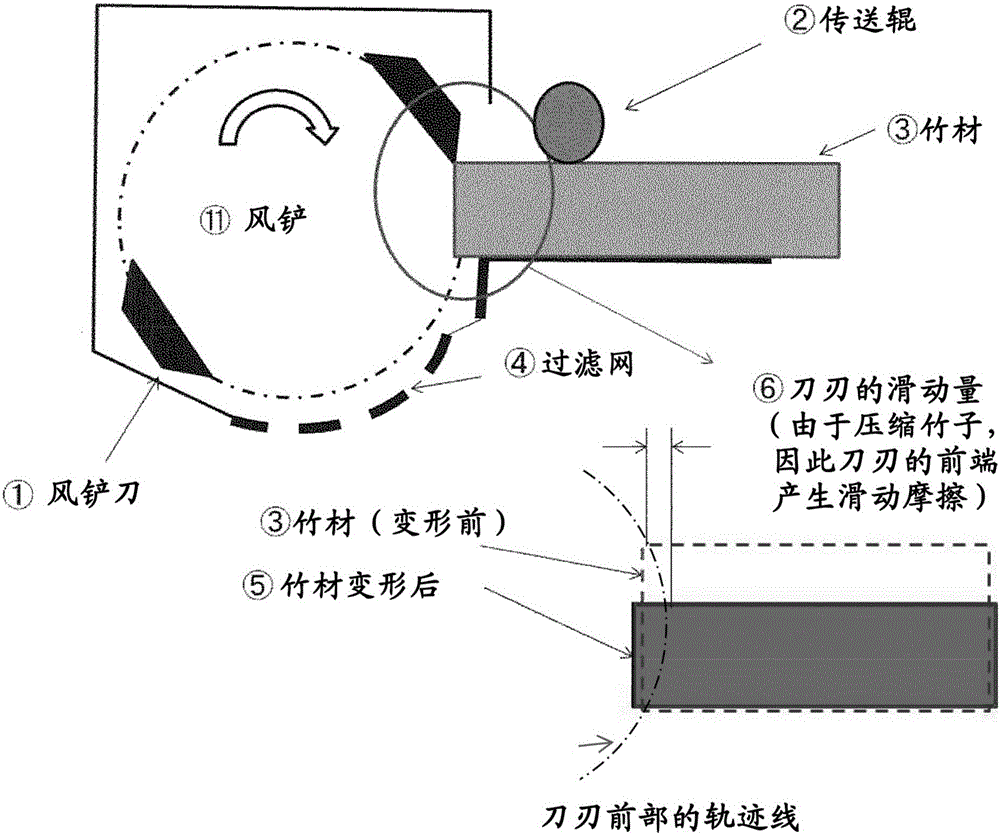

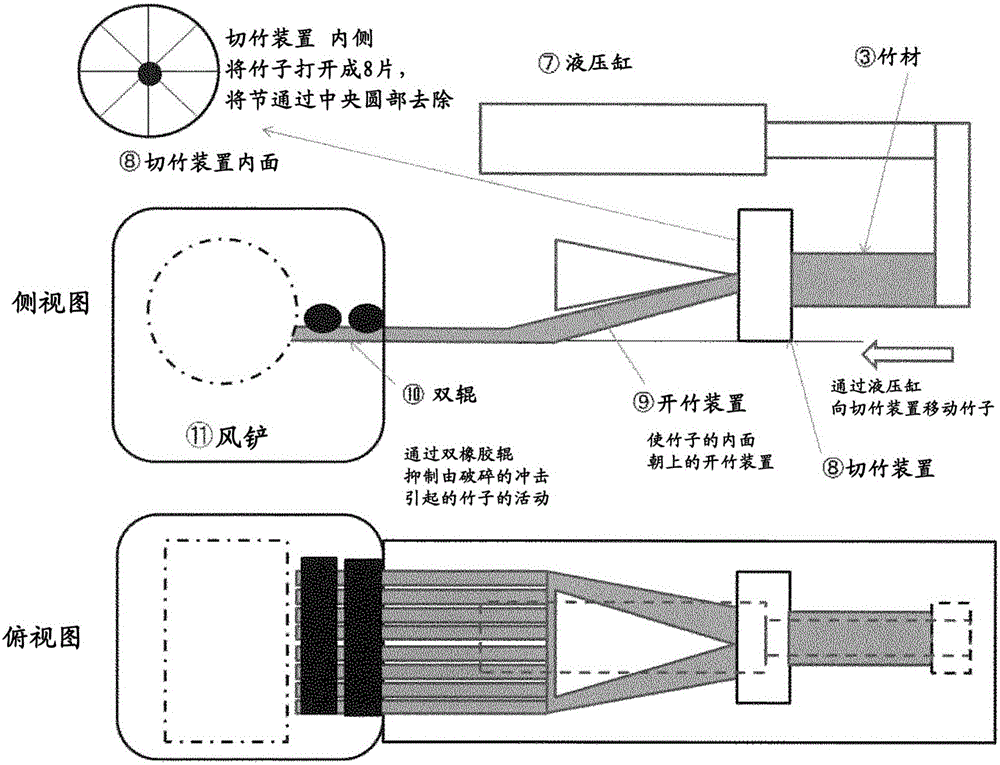

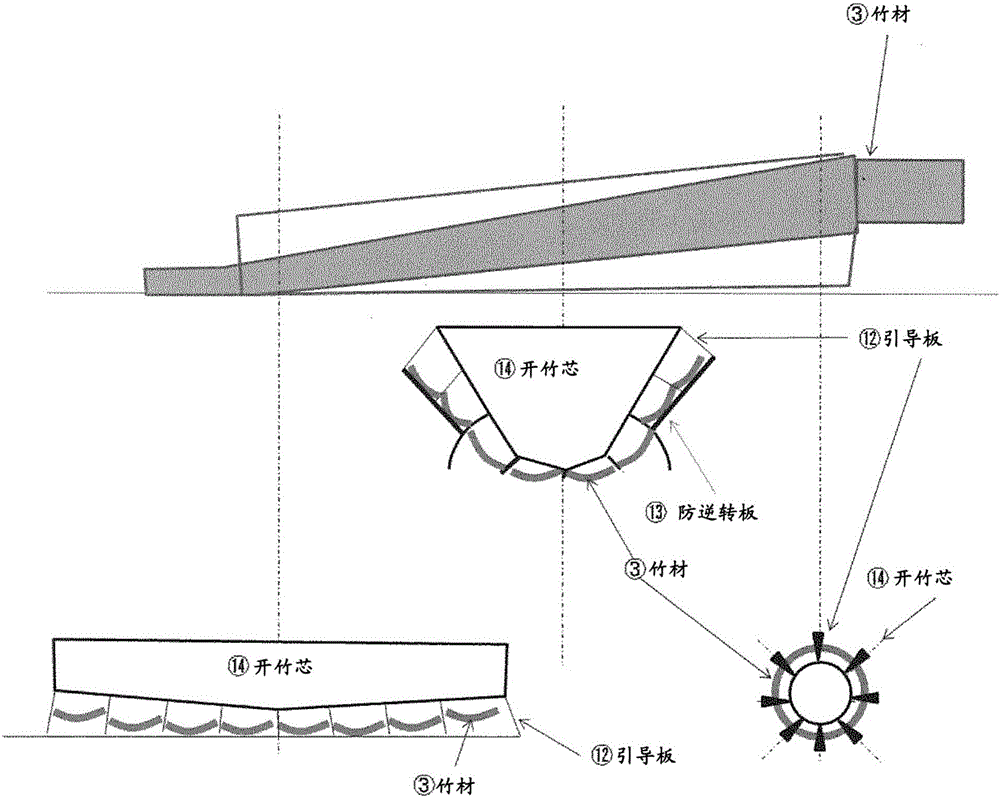

[0024] First, an example of a wind blade will be described using figures. For the air shovel 11, the air shovel 1 rotates at a high speed inside, and when the bamboo 3 is delivered to the inside of the air shovel 11 by the conveying roller 2, the air shovel 1 hits the bamboo 3, and the bamboo is cut off. The cut bamboo hits the blade or the like again inside the wind shovel 11 and is atomized. There is a filter screen 4 at the lower part of the wind shovel 11, and the bamboo that has been atomized into a size smaller than the filter screen 4 is discharged to the outside.

[0025] However, because bamboo has a cylindrical shape with a hollow inside, when the wind blade 1 hits the bamboo material 3 (before deformation), the substantially circular shape is deformed into an elliptical cross section by a compressive force. , and become the state of 5 after bamboo deformation. In addition, even if it is a slat-shaped bamboo cut in the vertical direction, the same deformation occur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com