Porcelain tile with full-body grain and texture and production method thereof

A production method and technology of porcelain tiles, applied in the direction of copying/marking methods, manufacturing tools, ceramic molding machines, etc., can solve the problems of lack, exposed bottom and unsightly appearance, and achieve the effect of saving cumbersome procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be specifically described below with reference to the accompanying drawings and in combination with embodiments.

[0039] a) Prepare porcelain brick body powder according to the conventional method, and prepare 3 kinds of color powder for standby;

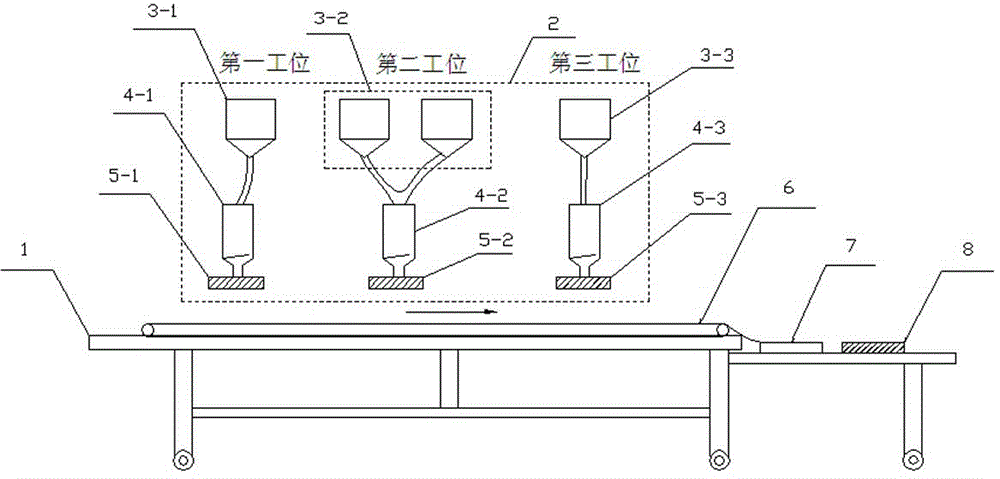

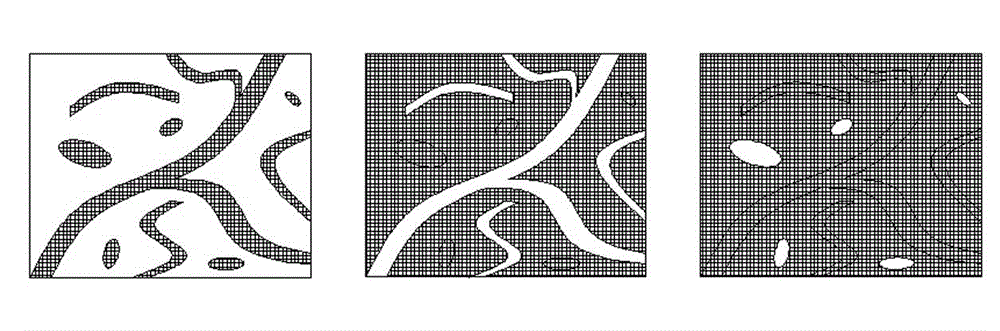

[0040] b) adopt the whole body cloth distributing device of the present invention to carry out cloth, such as Figure 1~2 As shown, the distributing device includes a frame 1, a multi-station distributing device 2, a main belt 6, a material receiving plate 7, and a pushing device 8 with a grid, wherein the multi-station distributing device 2 includes a group of powder supply devices 3. The hopper 4 and the flat screen 5, the powder supply device 3 is set above the hopper 4, the flat screen 5 with a certain pattern texture is set under the hopper 4, and the bottom of the flat screen 5 is set for carrying the plane screen. The main belt 6 of the lower powder, the main belt 6 is arranged on the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com