Porcelain tile having full-body grain and texture and preparation method of same

A ceramic tile, whole body technology, applied in the field of ceramic tile production, can solve problems such as deficiency, unsightly bottom exposure, etc., and achieve the effect of eliminating cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be specifically described below with reference to the accompanying drawings and in combination with embodiments.

[0039] a) Prepare porcelain brick body powder according to a conventional method, and prepare four kinds of color powder for subsequent use;

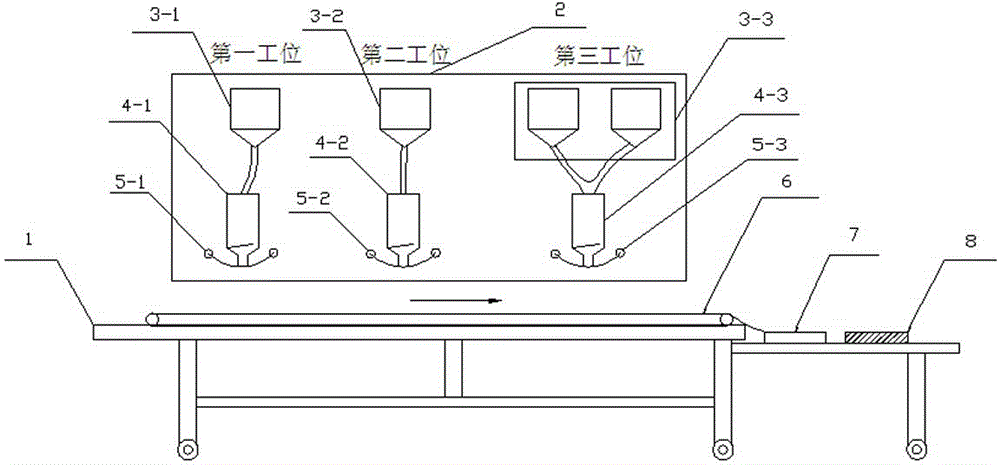

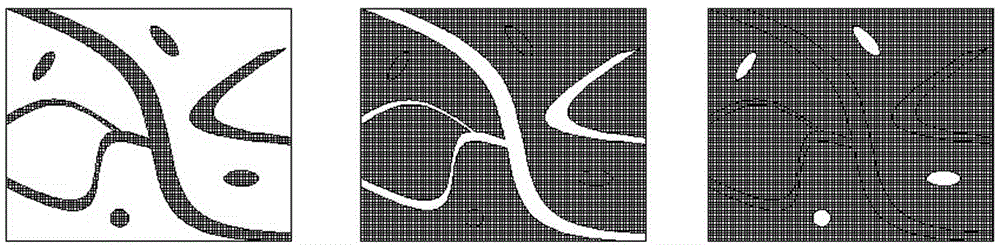

[0040] b) adopt the whole body cloth distributing device of the present invention to carry out cloth, such as Figure 1~2 As shown, the distributing device includes a frame 1, a multi-station distributing device 2, a main belt 6, a material receiving plate 7, and a pushing device 8 with a grid, wherein the multi-station distributing device 2 includes a group of powder supply devices 3. The hopper 4 and the curved mesh 5, the powder supply device 3 is arranged above the hopper 4, the curved mesh 5 with a certain pattern texture is arranged under the hopper 4, and the curved mesh 5 is arranged below the curved mesh for carrying the curved mesh. The main belt 6 of the lower powder, the main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com