Gas-releasing-type composite preservative film and preparing method thereof

A composite preservation and gas release technology, which is applied in the fields of fruit and vegetable preservation, chemical instruments and methods, food preservation, etc., can solve the problems of no controllability, no broad spectrum, short cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

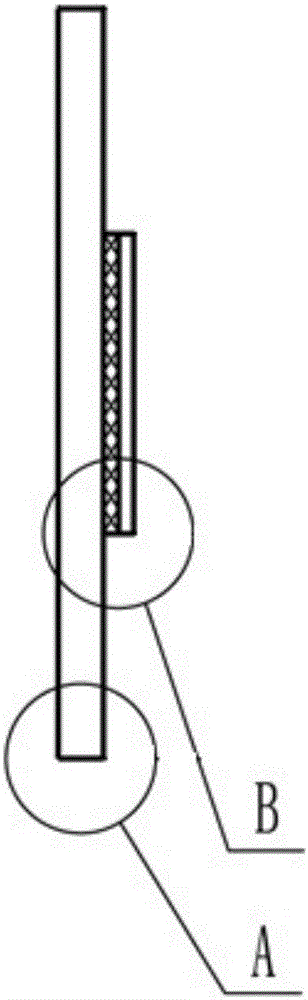

[0029] The invention provides a gas release type composite fresh-keeping film, such as figure 1 As shown, it includes the main body of the film and the self-adhesive layer, wherein the length of the main body of the film is longer than that of the self-adhesive layer, and both ends of the main body of the film stick out of the self-adhesive layer.

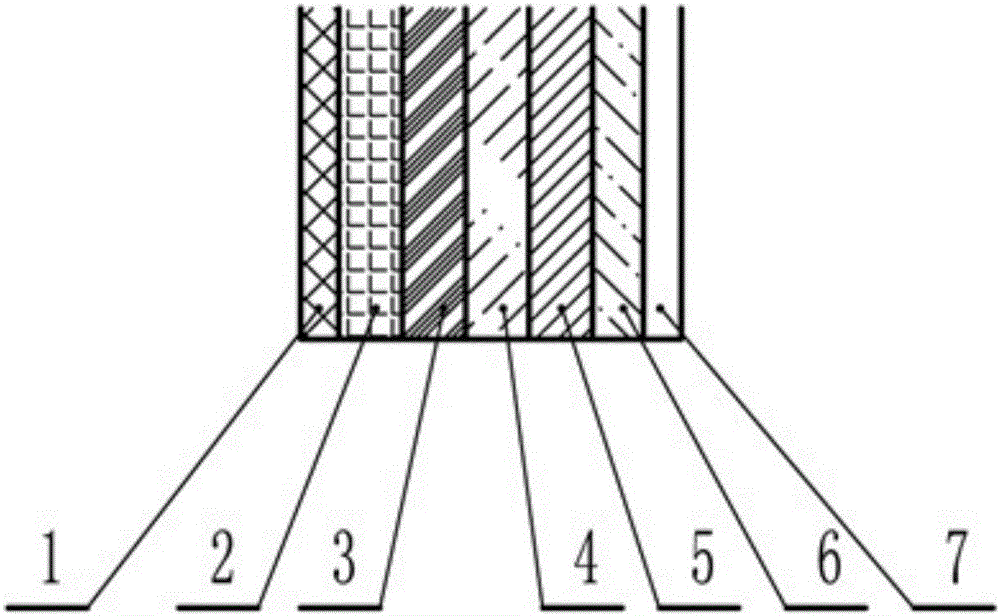

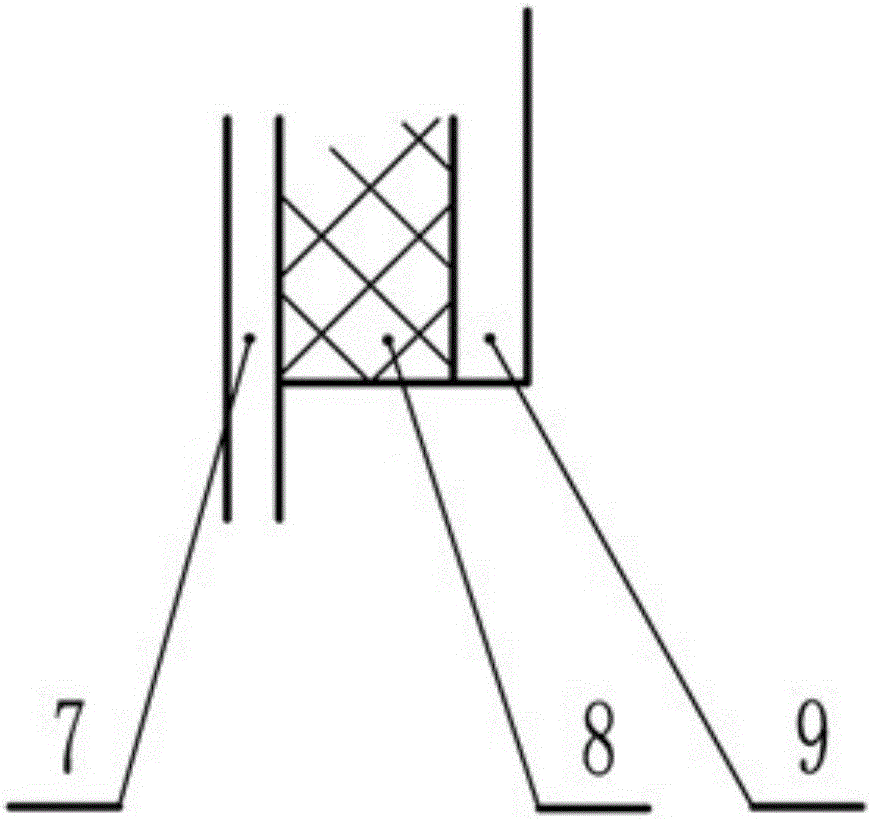

[0030] Such as figure 2 As shown, the film main body includes a release film with holes 2, a composite fresh-keeping coating 3, a silica gel coating 4, a polymer water-absorbing layer 5, an adhesive layer 6, and an isolation layer 7, which are sequentially coated together in layers; The other side of the release film 2 is also coated with a printing layer 1, and the printing layer 1 is a trademark or other patterns sprayed on graphite.

[0031] Wherein the release film 2 with holes is blown from an inorganic filler modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com