Method and device for simultaneously engraving and processing superposed glass

A technology for superimposing glass and fine carving processing, applied in the field of fine carving, can solve problems such as low processing efficiency and low production capacity, and achieve the effect of improving efficiency and production capacity and reducing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

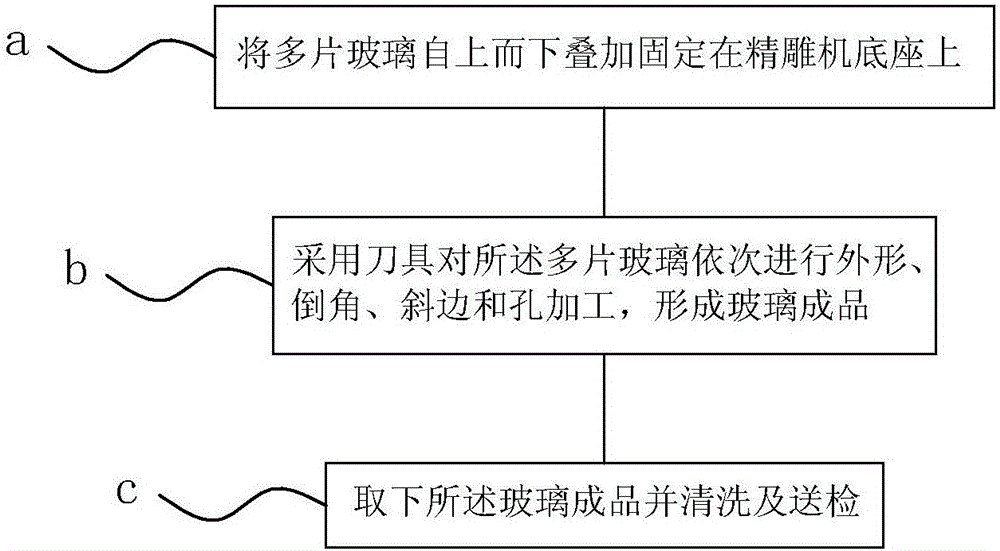

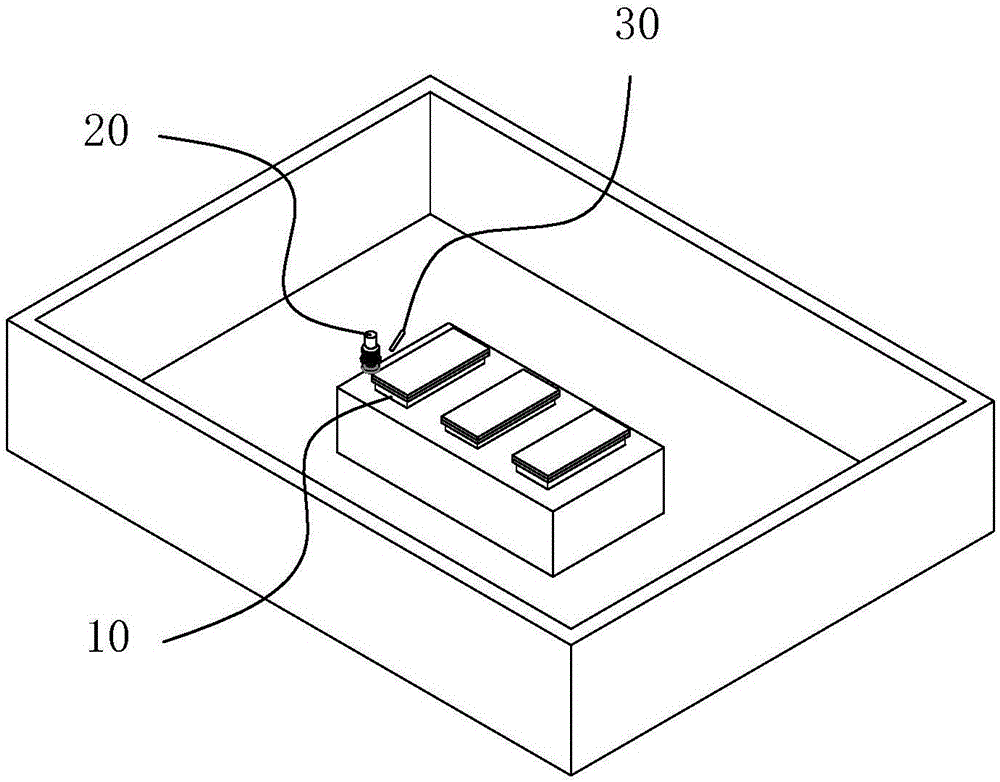

[0031] In order to achieve the effect of engraving and processing multiple pieces of superimposed glass at the same time on one engraving machine, such as figure 1 As shown, the present embodiment discloses a method for finely engraving and processing superimposed glass at the same time, which includes the following steps:

[0032] a. Superimpose and fix multiple pieces of glass on the base of the engraving machine from top to bottom;

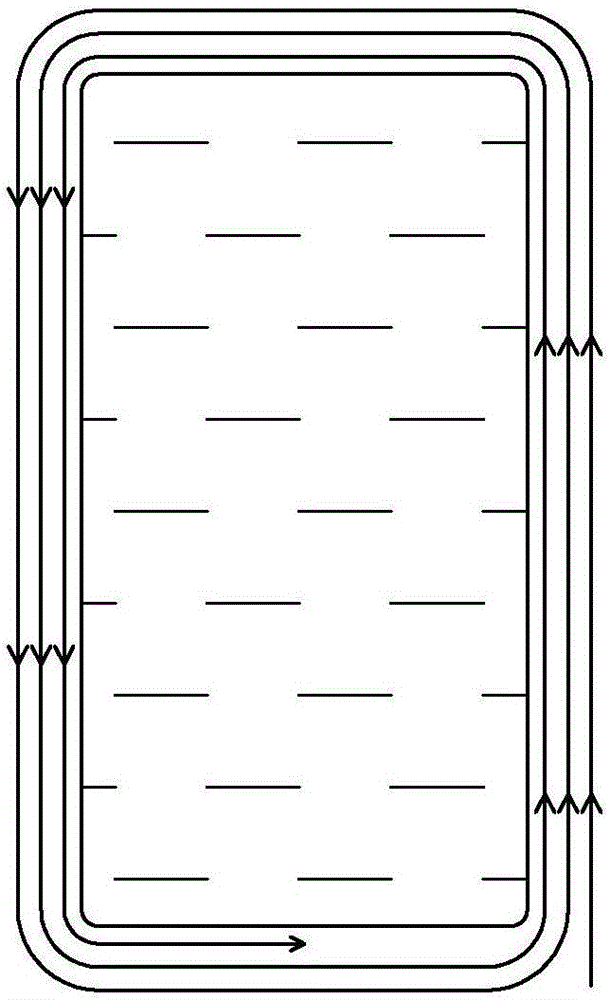

[0033] b. Use cutting tools to sequentially process shapes, chamfers, bevels and holes on multiple pieces of glass to form finished glass products;

[0034] c. Remove the finished glass and clean it and submit it for inspection.

[0035] Specifically, in step a, a freeze-fixation method is used to freeze and fix multiple pieces of stacked glass.

[0036] Freezing and fixing methods include: setting a freezing device on the base of the engraving machine; placing multiple pieces of glass on the freezing device; spraying cutting fluid on the gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com