Connector terminal assembly, electronic control unit, and electric power steering unit

A technology for electronic control devices and connector terminals, which is applied to power steering mechanisms, electric steering mechanisms, parts of connecting devices, etc., and can solve problems such as poor sealing, easy obstruction of the flow of sealant 37, and increased number of connector bodies 32, etc. problem, to achieve a reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

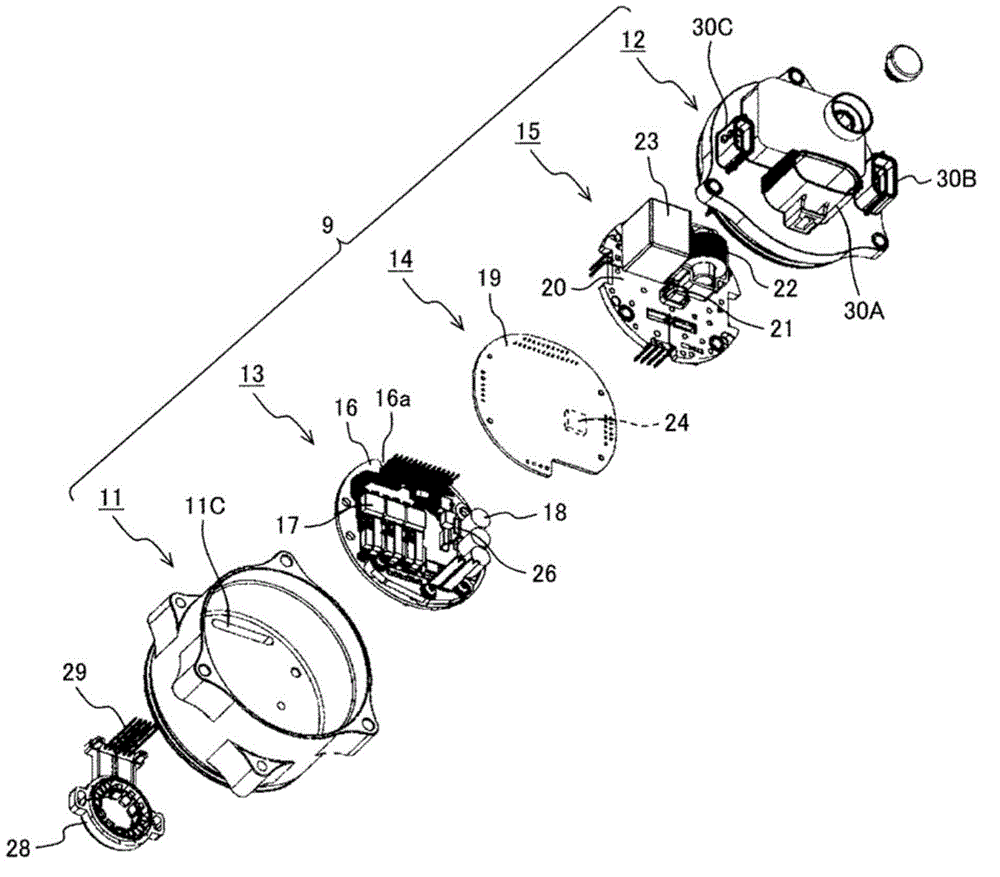

[0082] In order to cope with the above-mentioned poor sealing, the present embodiment proposes the following structure. That is, the bottom wall formed on the base of the connector terminal assembly is formed as an inclined surface, and the sealing material is injected so that the sealing material flows down due to gravity. Thereby, the sealant can be stably diffused and filled into the inner space of the base body by a simple method, so that the space between the base body and the connector main body can be reliably sealed.

[0083] Figure 4A The illustrated connector terminal portion represents a connector terminal portion 30B that transmits a detection signal from a sensor to the electronic control assembly. In the connector terminal part 30B, the base body 31B is composed of an inclined bottom wall 38 and a side wall 34 to form an internal space 35. The inclined bottom wall 38 is composed of an inclined surface inclined relative to the horizontal state, and the side wall...

Embodiment 2

[0091] Next, other embodiments of the present invention will be described. In this embodiment, the bottom wall formed on the base of the connector terminal assembly is formed of two inclined surfaces that incline downward and intersect, and the sealing material is injected so that the sealing material falls by gravity. Therefore, the sealant can be stably diffused and filled into the inner space of the base body by a simple method, and thus the space between the base body and the connector main body can be reliably sealed.

[0092] Figure 5A The illustrated terminal portion represents the connector terminal portion 30B of the connector terminal assembly 30 . In the connector terminal portion 30B, the base body 31B is composed of an inclined bottom wall 39 and a side wall 34 to form an internal space 35 . It stands vertically from the entire circumference of the inclined bottom wall 39 . The intersection position of the two inclined surfaces is near the approximate center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com