Inverted-umbrella-shaped aerator

An aerator and inverted umbrella-shaped technology, which is applied in the field of multifunctional surface aerators, can solve the problems of not considering the pushing flow ability, the reduction of the pushing and stirring effect of the aerator, and the inability to guarantee the pushing flow area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is specifically introduced as follows:

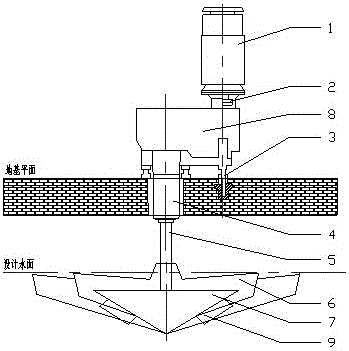

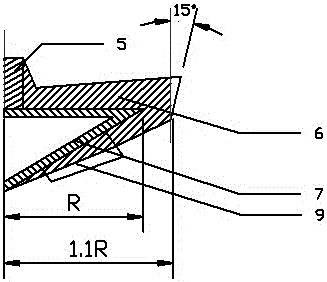

[0021] figure 1 It is a structural schematic diagram of an inverted umbrella aerator of the present invention, including a motor 1, a coupling 2, a lifting device 3, an inverted umbrella seat 4, an impeller shaft 5, an inverted umbrella long blade 6, an inverted umbrella cone 7, and a reduction box 8 and inverted umbrella short blade 9. In the structure, the number of long and short blades is required to be an even number, so that the short blade can be located between two long blades to make the pushing flow more uniform; in addition, because the height of the short blade is higher than that of the long blade, it is not necessary In the case of changing the structure, the push flow capability of the short blades is further enhanced.

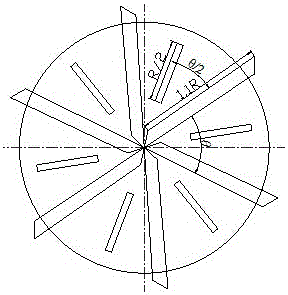

[0022] combine figure 2 , in the design process, the short vanes are located in the middle of the inverted cone surface, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com