Adjustable integrated impeller for reverse umbrella aerator

An aerator and adjustable technology, which is applied in the field of impeller, can solve the problems of unreasonable energy-saving strategies and affect energy saving and consumption reduction in the sewage treatment process, and achieve the effects of enhanced push flow effect, enhanced aeration function, and changed load status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

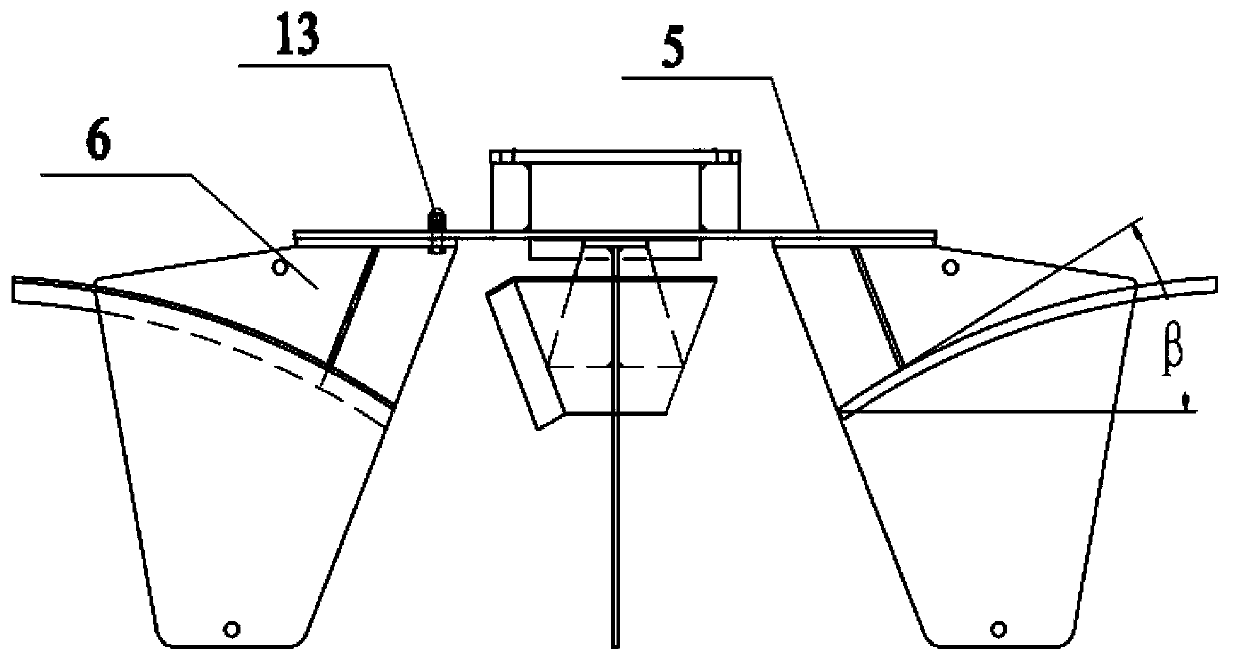

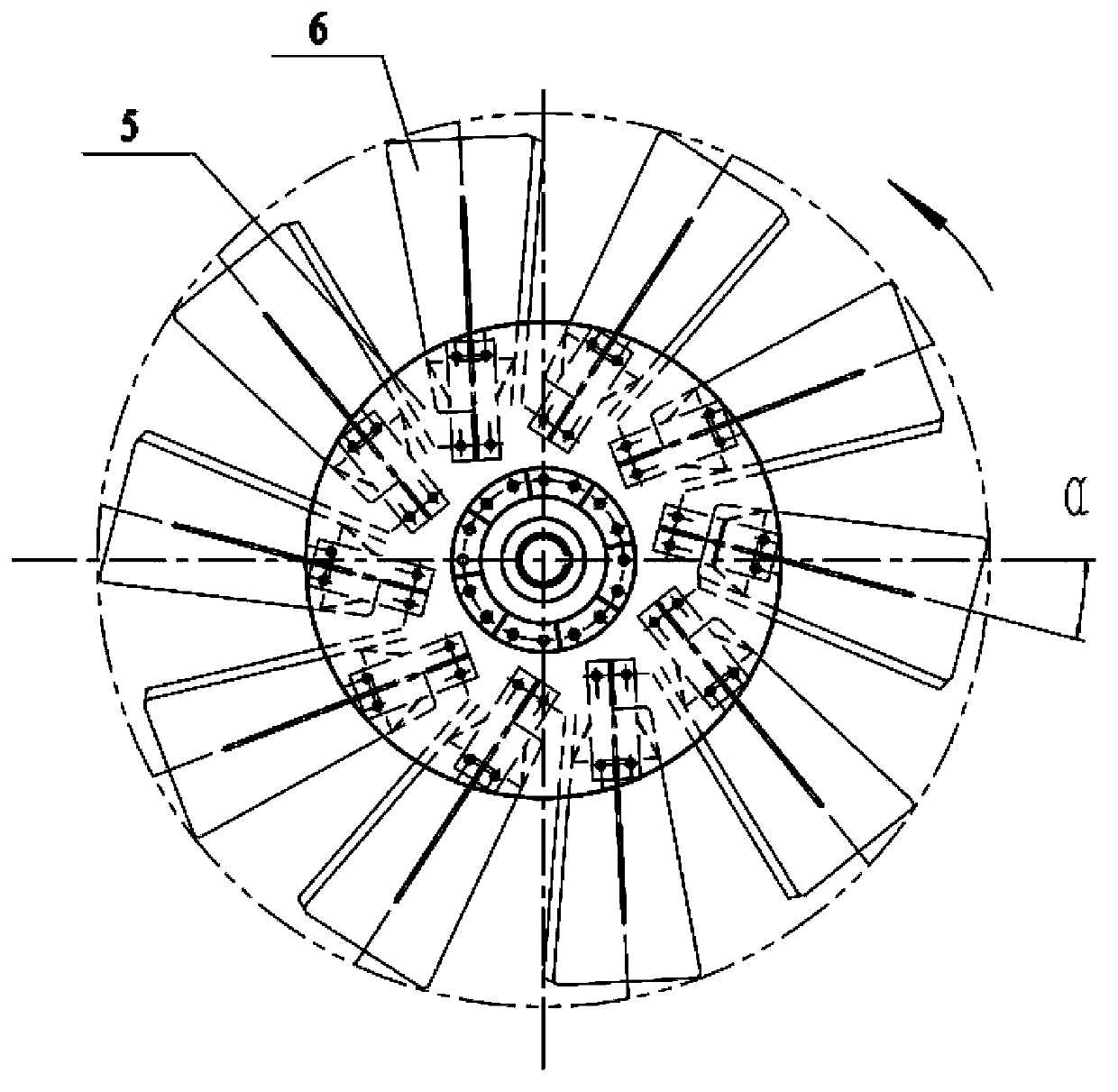

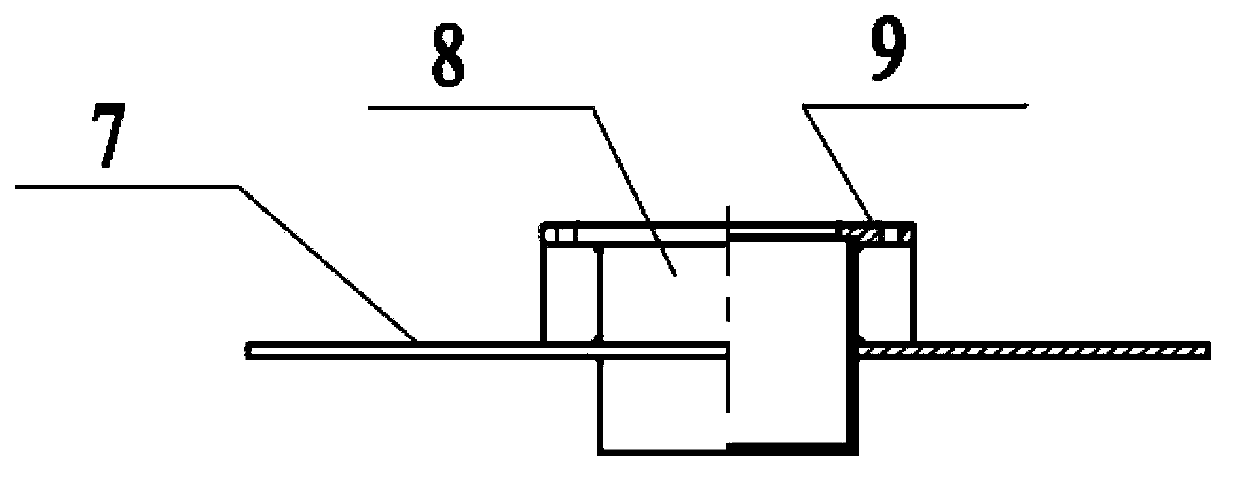

[0033] like Figure 1 to Figure 6 As shown, the present invention provides an adjustable integrated impeller used in an inverted umbrella aerator, which consists of an impeller gusset plate 5 and a plurality of blades 6, and the diameter of the impeller is 1200 mm to 3500 mm. By adjusting the diameter of the impeller, the impeller The load state is significantly changed. The number of blades 6 is 8-12, and they are evenly distributed on the bottom of the impeller gusset plate 5 , and the blades 6 are vertically installed on the bottom of the impeller gusset plate 5 through bolts 13 . Wherein, the impeller node plate 5 is composed of an impeller shaft 8 and a center plate 7 sheathed on the outer side of the impeller shaft 8 , and an impeller flange 9 is installed on the top end surface of the impeller shaft 8 . Blade installation holes 14 for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com