Method for preparing forward-switched reversible thermochromic composite film

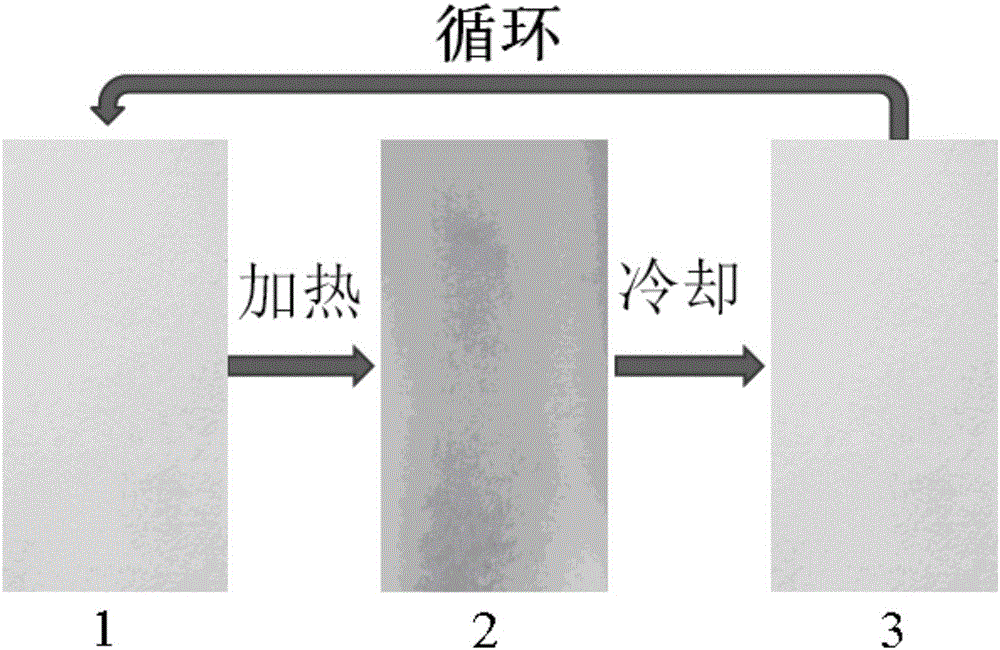

A composite film and temperature-sensitive discoloration technology, which is applied in the field of preparation of reversible discoloration composite films, can solve the problems of destroying the apparent integrity and affecting the appearance, and achieve the effect of maintaining product integrity, low cost, and sensitive discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] Specific embodiments: This embodiment is a method for preparing a positive switch temperature-induced reversible color composite film, which is completed according to the following steps:

[0027] 1. Glass plate pretreatment: use deionized water to rinse the surface of the glass plate, and then use absolute ethanol to rinse to obtain a pretreated glass plate;

[0028] 2. Add polyvinyl alcohol and dextrin to deionized water, then magnetically stir the reaction at a temperature of 70°C to 75°C and a stirring speed of 750r / min to 850r / min for 2h to 2.5h, and then stand at room temperature for 1h ~2h, to obtain a mixed solution;

[0029] The mass of polyvinyl alcohol described in step 2 and the volume ratio of deionized water are 2g:(90mL~100mL);

[0030] The mass of dextrin described in step 2 and the volume ratio of deionized water are 2g:(90mL~100mL);

[0031] 3. Add the temperature-sensitive color-changing material to the mixed solution obtained in step 2, then stir t...

specific Embodiment approach 2

[0043] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the dextrin described in step 2 is white dextrin. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0044] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the size of the glass plate in Step 1 is 80mm×40mm. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com