LED lamp bulb assembly with high heat dissipation performance

A LED light bulb, high heat dissipation technology, applied in the components of lighting devices, semiconductor devices of light-emitting elements, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

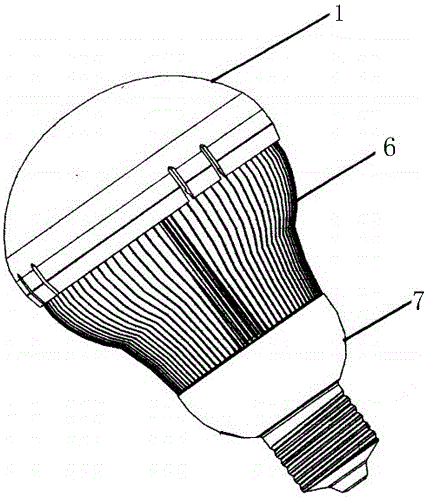

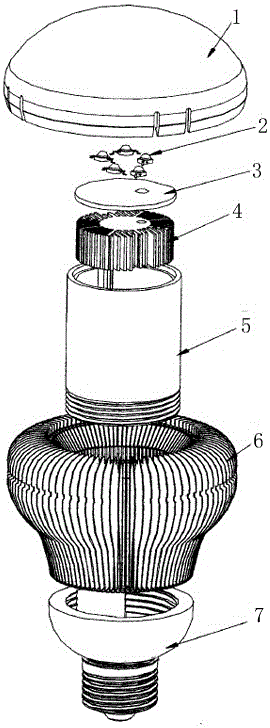

[0051] See figure 1 , figure 2 As shown, a LED light bulb assembly with high heat dissipation performance includes a lampshade 1, an LED lighting assembly 2, an aluminum-based PCB3, a heat sink, a power drive module (not shown in the figure) and a lamp holder 7. The power drive module device In the base 7, the heat sink includes a heat conduction plate 4, a hollow heat conduction column 5 and heat dissipation fins 6, and the lampshade 1 is connected with the heat dissipation fins 6 through buckles, and the heat dissipation fins 6 The lower end is fixed with a lamp holder 7, wherein a heat dissipation paint is coated between the heat conduction plate 4 and the aluminum-based PCB3; the hollow heat conduction column 5 is made of silicon carbide material, and a There are several heat dissipation holes 50, the heat conduction plate 4 and the hollow heat conduction column 5 are arranged in the hollow cavity of the heat dissipation fin 5, and a number of heat dissipation grooves (n...

Embodiment 2

[0066] An LED light bulb assembly with high heat dissipation performance, including a lampshade 1, an LED lighting assembly 2, an aluminum-based PCB3, a heat sink, a power drive module (not shown in the figure) and a lamp holder 7, the power drive module is installed in the In the base 7, the radiator includes a heat conduction plate 4, a hollow heat conduction column 5 and heat dissipation fins 6, the lampshade 1 is connected with the heat dissipation fins 6 through buckles, and the lower end of the heat dissipation fins 6 is fixed with Lamp holder 7, wherein a heat dissipation paint is coated between the heat conduction plate 4 and the aluminum-based PCB3; the hollow heat conduction column 5 is made of silicon carbide material, and several heat dissipation plates are arranged on the surface of the hollow heat conduction column. hole 50, the heat conduction plate 4 and the hollow heat conduction column 5 are set in the hollow cavity of the heat dissipation fin 5, and a number ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com