Composite functional phase change microcapsule and preparation method thereof

A phase-change microcapsule and functional technology, applied in the direction of microcapsule preparation, microsphere preparation, botanical equipment and methods, etc., can solve the problems of single function and loss of microcapsules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

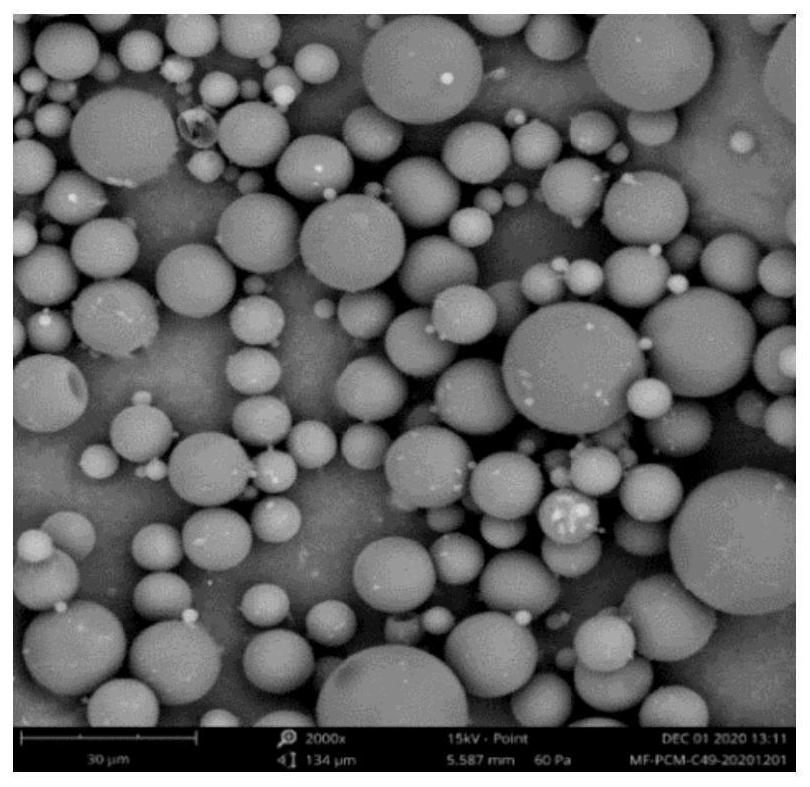

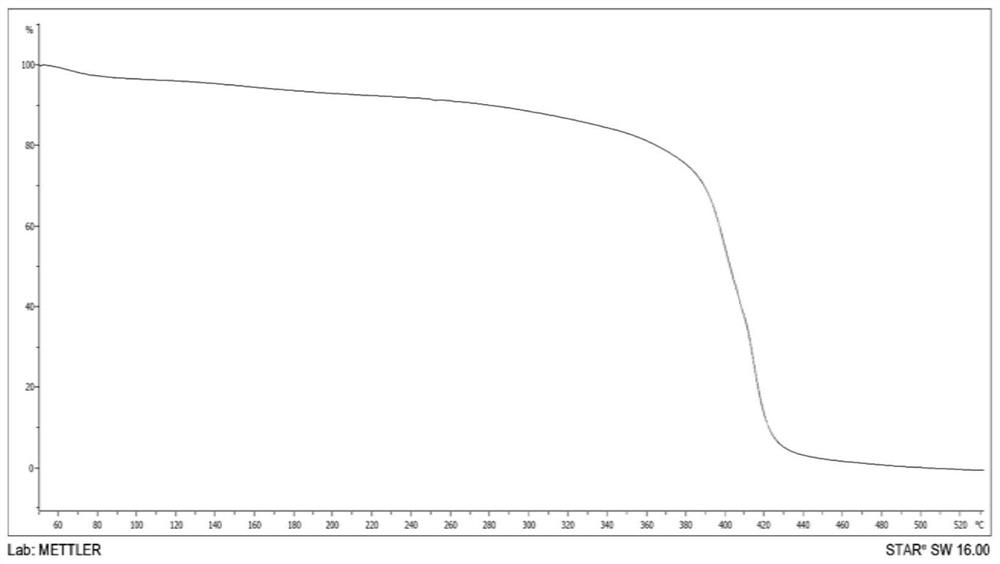

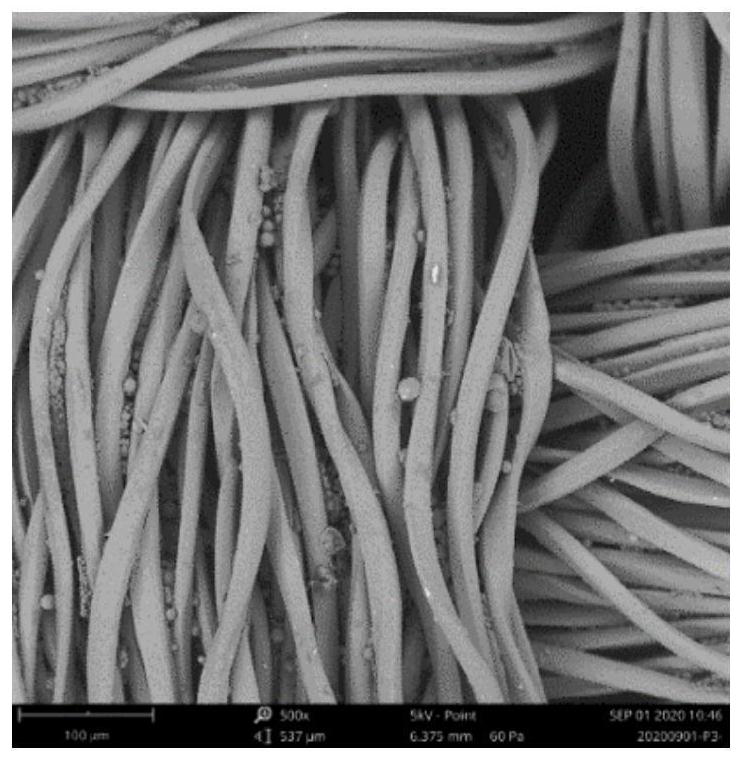

Image

Examples

Embodiment 1

[0035] A preparation method of composite functional phase change microcapsules, the specific steps are as follows:

[0036] Step 1: AgNO3 solution with anatase TiO 2 Nano-Ag / TiO under Irradiation of Photocatalytic Reactor 2 .

[0037] 2.26g of 10% AgNO 3 Add the solution dropwise to 100mL ultrapure water, then weigh 5g of glucose and 0.54g of anatase TiO 2 Dissolve in 100mL ultrapure water. The dissolved solution was poured into a 500ml beaker wrapped in tin foil and mixed, and reacted for 60 minutes under the irradiation of a photocatalytic reactor to obtain nano Ag / TiO 2 .

[0038] Step 2: Prepare composite core material emulsion, which contains phase change material, functional essential oil and polymer emulsifier.

[0039] ①Water phase preparation: Weigh 15g of emulsifier SMA (sodium salt solution of styrene-maleic anhydride copolymer) and 50g of deionized water in the reactor, heat to 40°C, start stirring at a stirring speed of 1000r / min, until The solution is clea...

Embodiment 2

[0052] A preparation method of composite functional phase change microcapsules, the specific steps are as follows:

[0053] Step 1: AgNO 3 solution with anatase TiO 2 Nano-Ag / TiO under Irradiation of Photocatalytic Reactor 2 .

[0054] 2.26g of 10% AgNO 3 Add the solution dropwise to 100mL ultrapure water, then weigh 4g of glucose and 0.34g of anatase TiO 2 Dissolve in 100mL ultrapure water. The dissolved solution was poured into a 500ml beaker wrapped in tin foil and mixed, and reacted for 60 minutes under the irradiation of a photocatalytic reactor to obtain nano Ag / TiO 2 .

[0055] Step 2: Prepare composite core material emulsion, which contains phase change material, functional essential oil and polymer emulsifier.

[0056] ①Water phase preparation: Weigh 3g of emulsifier PVA and 50g of deionized water in the reactor, heat to 40°C, start stirring at a stirring speed of 1000r / min until the solution is clear and transparent;

[0057] ②Oil phase preparation: Weigh 23g...

Embodiment 3

[0069] A preparation method of composite functional phase change microcapsules, the specific steps are as follows:

[0070] Step 1: AgNO 3 solution with anatase TiO 2 Nano-Ag / TiO under Irradiation of Photocatalytic Reactor 2 .

[0071] 2.26g of 10% AgNO 3 Add the solution dropwise to 100mL ultrapure water, then weigh 4g of glucose and 0.4g of anatase TiO 2 Dissolve in 100mL ultrapure water. The dissolved solution was poured into a 500ml beaker wrapped in tin foil and mixed, and reacted for 60 minutes under the irradiation of a photocatalytic reactor to obtain Ag / TiO 2 nanocomposites.

[0072] Step 2: Prepare composite core material emulsion, which contains phase change material, functional essential oil and polymer emulsifier.

[0073] ①Water phase preparation: Weigh 7.2g of emulsifier SMA (sodium salt solution of styrene-maleic anhydride copolymer), 50g of deionized water in the reactor, heat to 40°C, and start stirring at a stirring speed of 1000r / min. until the solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com