Preparation method for copper-tin-nickel-bismuth alloy powder used for producing thermometal bearing bush material

A bimetallic shaft and alloy powder technology, which is applied in the field of preparation of copper-tin-nickel-bismuth alloy powder, can solve the problems of lead toxicity and hazards, and achieve the effects of good density, improved jacquard rate, and high energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

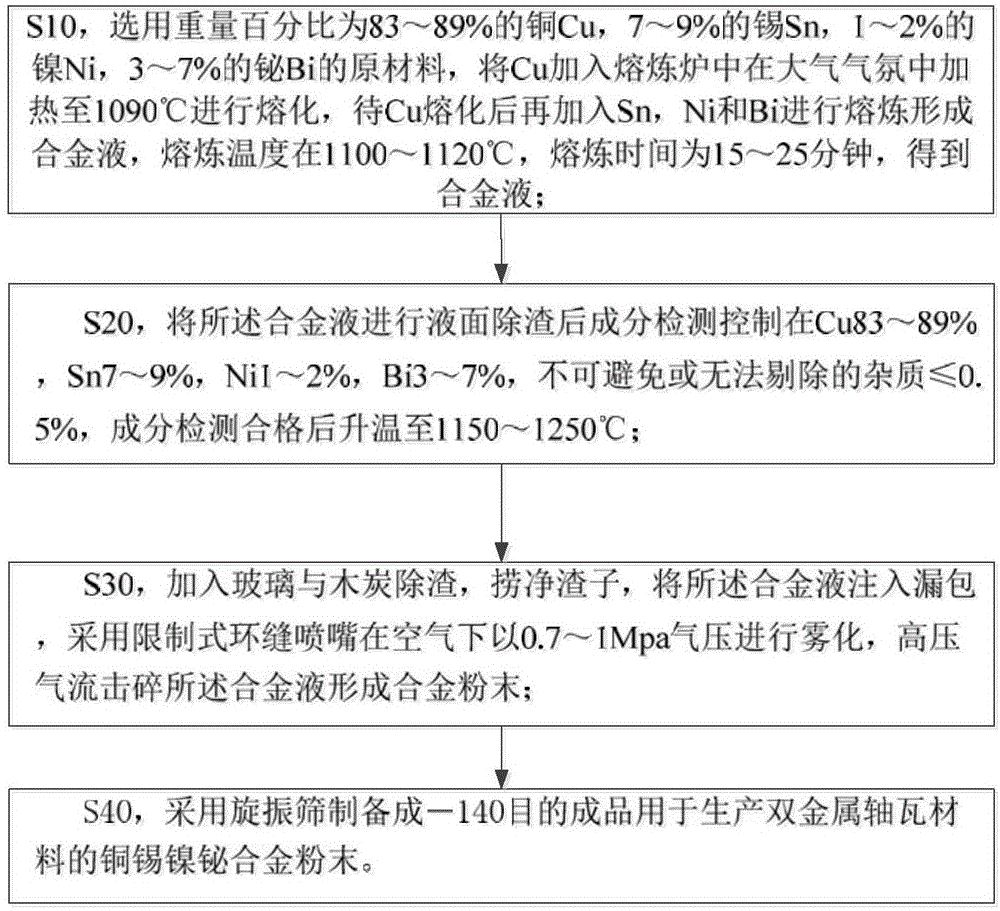

[0025] Such as figure 1 as shown, figure 1 It is a flowchart of a method for preparing copper-tin-nickel-bismuth alloy powder for producing bimetallic bearing materials according to an embodiment of the present invention.

[0026] A kind of preparation method of the copper-tin-nickel-bismuth alloy powder that is used to produce bimetal bearing material of this embodiment, alloy powder comprises two kinds of grades of CuSn8Ni1Bi4 and CuSn8Ni1Bi6, comprises the following steps,

[0027] S10, select the raw material that is 83% copper by weight, 9% tin, 1% nickel, 7% bismuth, put Cu into the smelting furnace and heat to 1090°C in the atmosphere to melt, and then melt the copper after melting. Add Sn, Ni and Bi for melting to form alloy liquid, the melting temperature is 1100°C, and the melting time is 15 minutes; when the Sn content is less than 10%, the increase of Sn content is beneficial to improve the strength of the final product;

[0028] S20, after removing slag from the...

Embodiment 2

[0034] Such as figure 1 as shown, figure 1 It is a flowchart of a method for preparing copper-tin-nickel-bismuth alloy powder for producing bimetallic bearing materials according to an embodiment of the present invention.

[0035] A kind of preparation method of the copper-tin-nickel-bismuth alloy powder that is used to produce bimetallic bearing material of the present embodiment comprises the following steps,

[0036] S10, select the raw material of 89% copper, 7% tin, 1% nickel, and 3% bismuth by weight, add Cu to the smelting furnace and heat it to 1083°C in the atmosphere for melting, and then melt it after the copper is melted Add Sn, Ni and Bi for melting to form alloy liquid, the melting temperature is 1120°C, and the melting time is 25 minutes; when the Sn content is less than 10%, the increase of Sn content is beneficial to improve the strength of the final product;

[0037] S20, after removing slag from the liquid surface, the composition detection of the alloy li...

Embodiment 3

[0043] Such as figure 1 as shown, figure 1 It is a flowchart of a method for preparing copper-tin-nickel-bismuth alloy powder for producing bimetallic bearing materials according to an embodiment of the present invention.

[0044] A kind of preparation method of the copper-tin-nickel-bismuth alloy powder that is used to produce bimetallic bearing material of the present embodiment comprises the following steps,

[0045]S10, select the raw materials of 86% copper, 8% tin, 1.5% nickel, and 4.5% bismuth by weight, add Cu to the smelting furnace and heat it to 1085°C in the atmosphere for melting, and then melt it after the copper is melted Add Sn, Ni and Bi for melting to form alloy liquid, the melting temperature is 1110°C, and the melting time is 20 minutes; when the Sn content is less than 10%, the increase of Sn content is beneficial to improve the strength of the final product;

[0046] S20, after removing slag from the liquid surface, the composition detection of the allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com