Laminated floor and manufacturing method thereof

A composite floor and manufacturing method technology, applied in manufacturing tools, chemical instruments and methods, building structures, etc., can solve the problems of difficult quality control, long processing cycle, inability to solve the stable and differential deformation of the surface plate and the base material, etc. The effect of overcoming differences in stability, simple structure, and suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

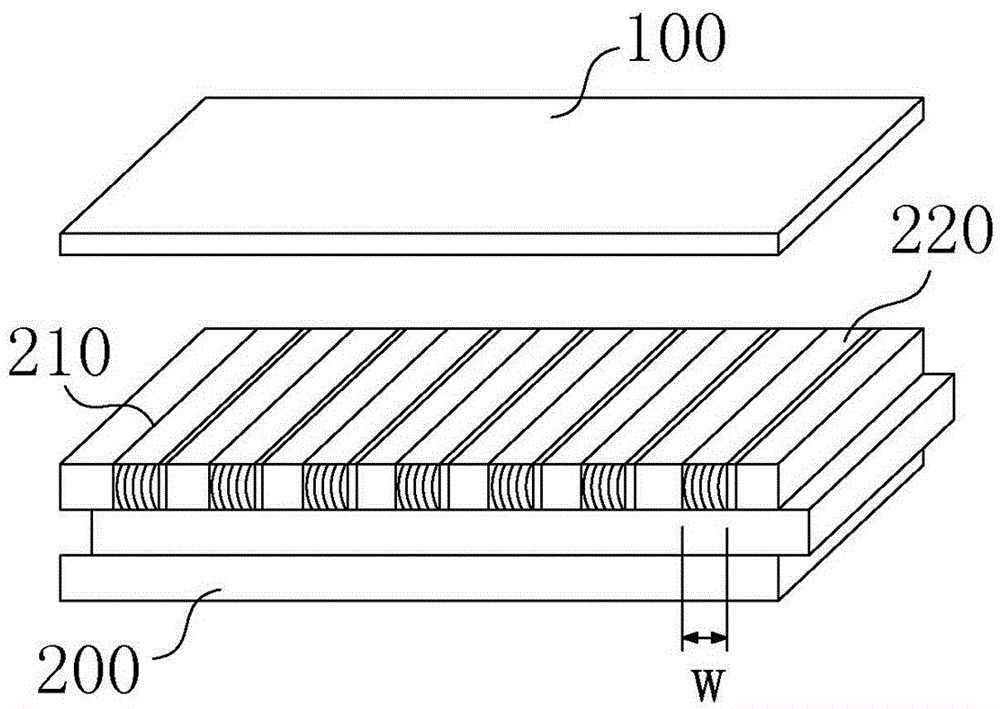

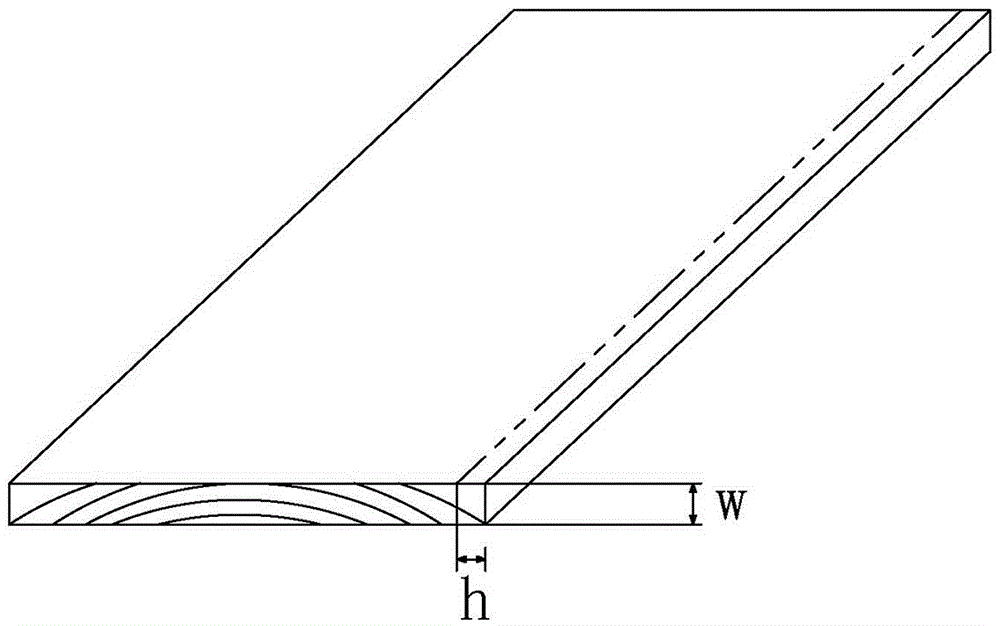

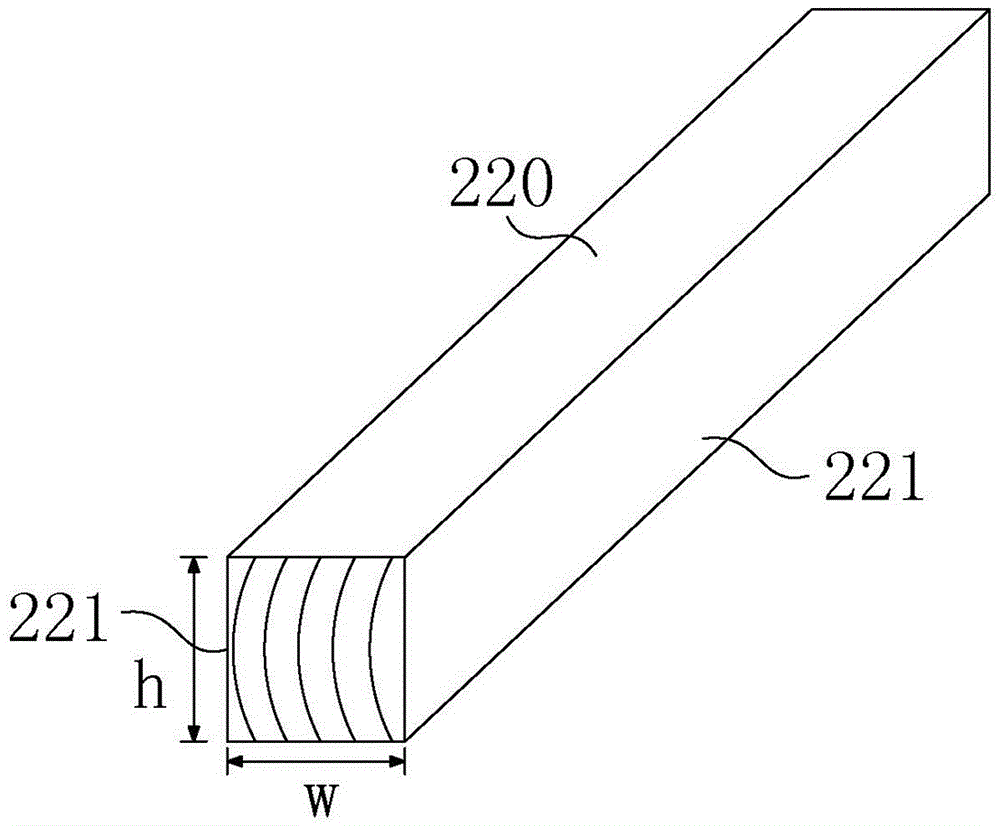

[0043] Example: such as figure 1 with 3 Shown is a composite floor with a specification of 2100mm*195mm*26mm, including 2mm thick red rubber sheet 100 and 24mm thick oriented strand board substrate 200 with glued links. The surface of the substrate 200 (the surface glued to the sheet 100 Regarding the front side of the substrate 200), 17 embedding grooves 210 with a rectangular cross section are penetrated at equal intervals, and embedding strips 220 of fast-growing poplar wood are arranged in the embedding grooves 210. The specification of the embedding groove 210 (groove width * groove depth * groove length) is 50mm*6mm*195mm, and the setting distance is 50mm; the specification of the rectangular strip 220 (strip width * strip thickness * strip length) is 45mm * 6mm *195mm. The molding 220 is made by compression and densification on both sides, so it includes two compression surfaces. The distance between the two compression surfaces is the width of the molding 220 and the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com