Intelligent drilling water pressing testing equipment

A technology of pressurized water test and equipment, which is applied in earth-moving drilling, surveying, wellbore/well components, etc., can solve the problems of complex operation, unresolved technical problems, and high difficulty in operation, and achieves simple operation, light weight, The effect of high data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

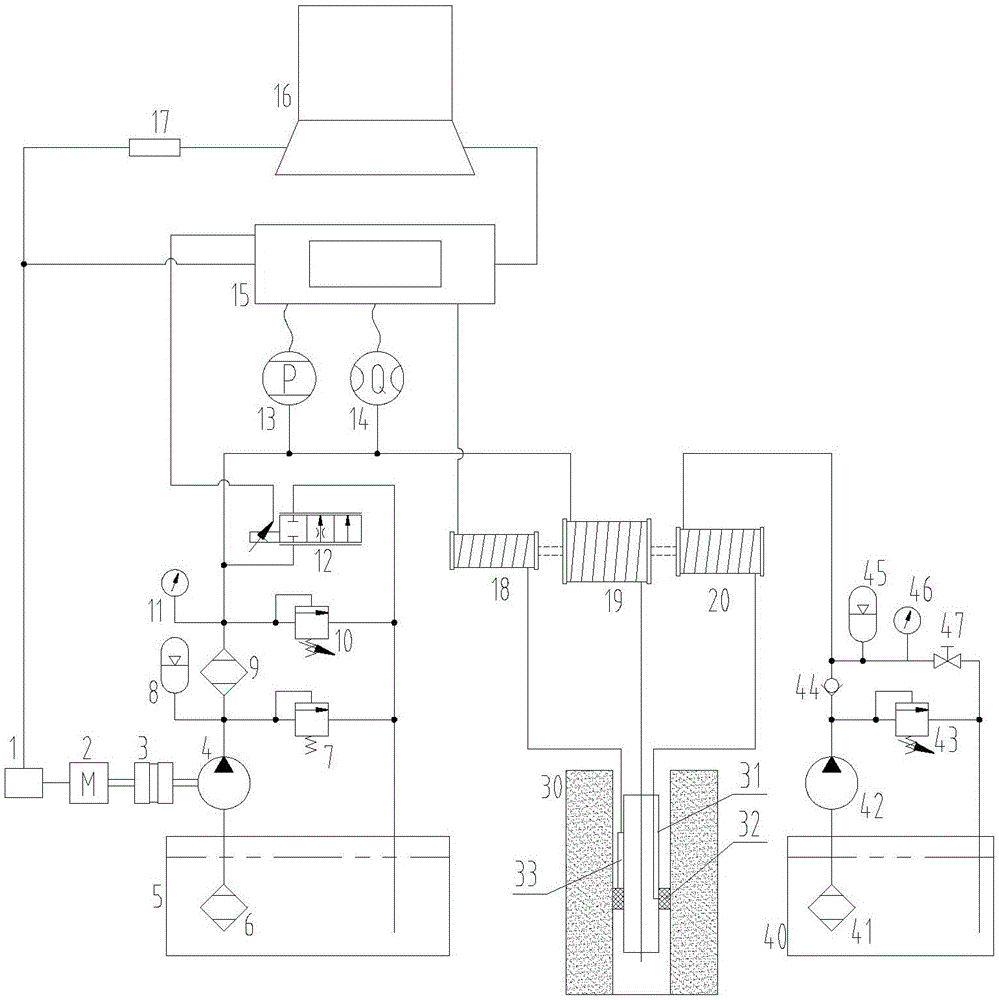

[0043] Please refer to the attached figure 1 , this embodiment includes a water supply system, a water pressure regulating system, a data acquisition system, a data processing system, and an embolism pressure supply system, the water supply system, the data acquisition system, and the embolism pressure supply system are connected to each other, and the data processing system is connected to the data acquisition system system.

[0044] In this embodiment, the water supply system includes an engine 2, a coupling 3, a water supply pump 4, a water supply storage tank 5, a water supply suction filter 6, a safety valve 7, a pressure stabilizing tank 8, a water supply outlet filter 9 and a pressure water pipe Hoisting 19, one end of the engine 2 is connected to the data acquisition system, the other end of the engine 2 is connected to the coupling 3, the water supply pump 4, the safety valve 7, the surge tank 8 and the water supply and outlet filter 9 are connected to each other, so ...

Embodiment 2

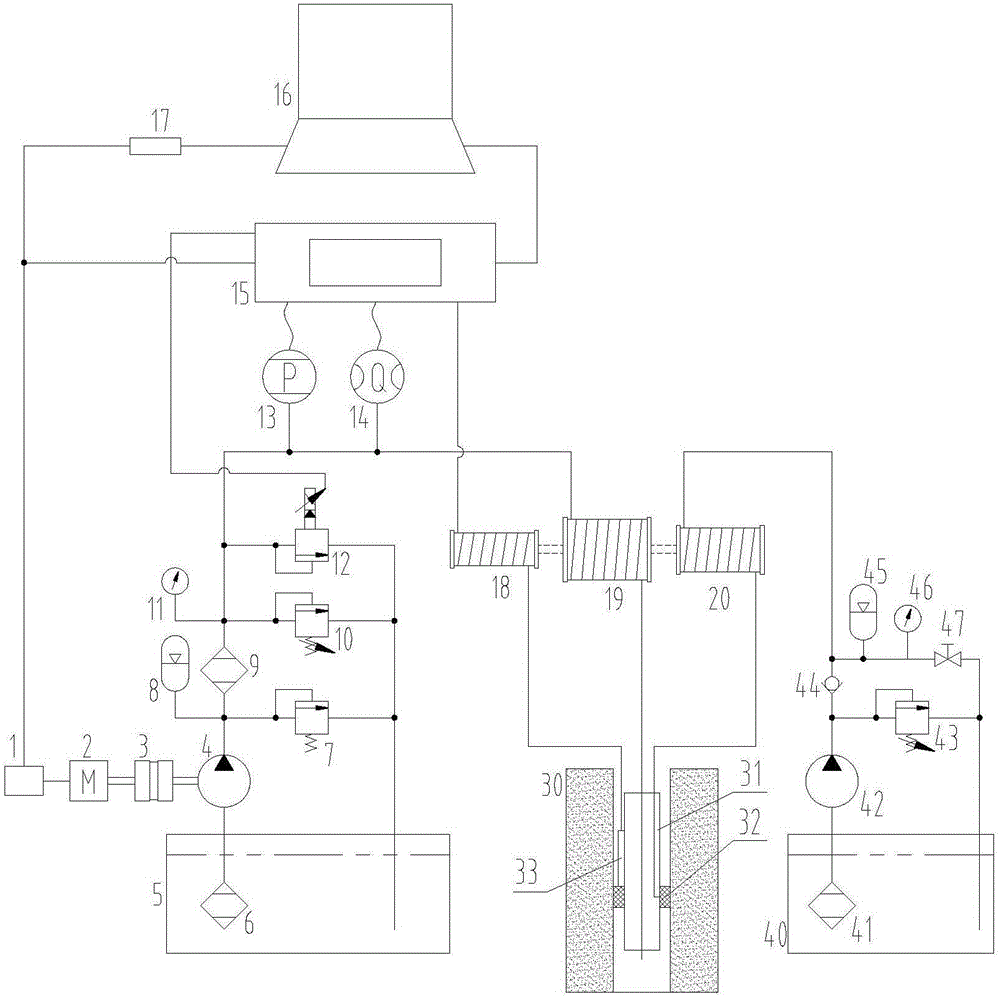

[0087] Refer to attached figure 2 , Figure 9-Figure 11 , The difference between this embodiment and Embodiment 1 is that the electric proportional pressure regulating valve 12 adopts an electric proportional overflow valve, and the rest are basically the same as Embodiment 1.

[0088] The high degree of intelligence improves the work efficiency, reduces the labor intensity of the operator, and improves the accuracy of the test results; the data accuracy is high; the output flow of the water pump is stable, and the pressure regulator tank and the electric proportional pressure regulating valve in the water supply system are in good condition. It has the function of voltage stabilization; light in weight; the software authority is classified and managed, and the test test data is supervised; it provides a complete set of solutions for the drilling water pressure test process, with high integration; the operation is simple and convenient.

Embodiment 3

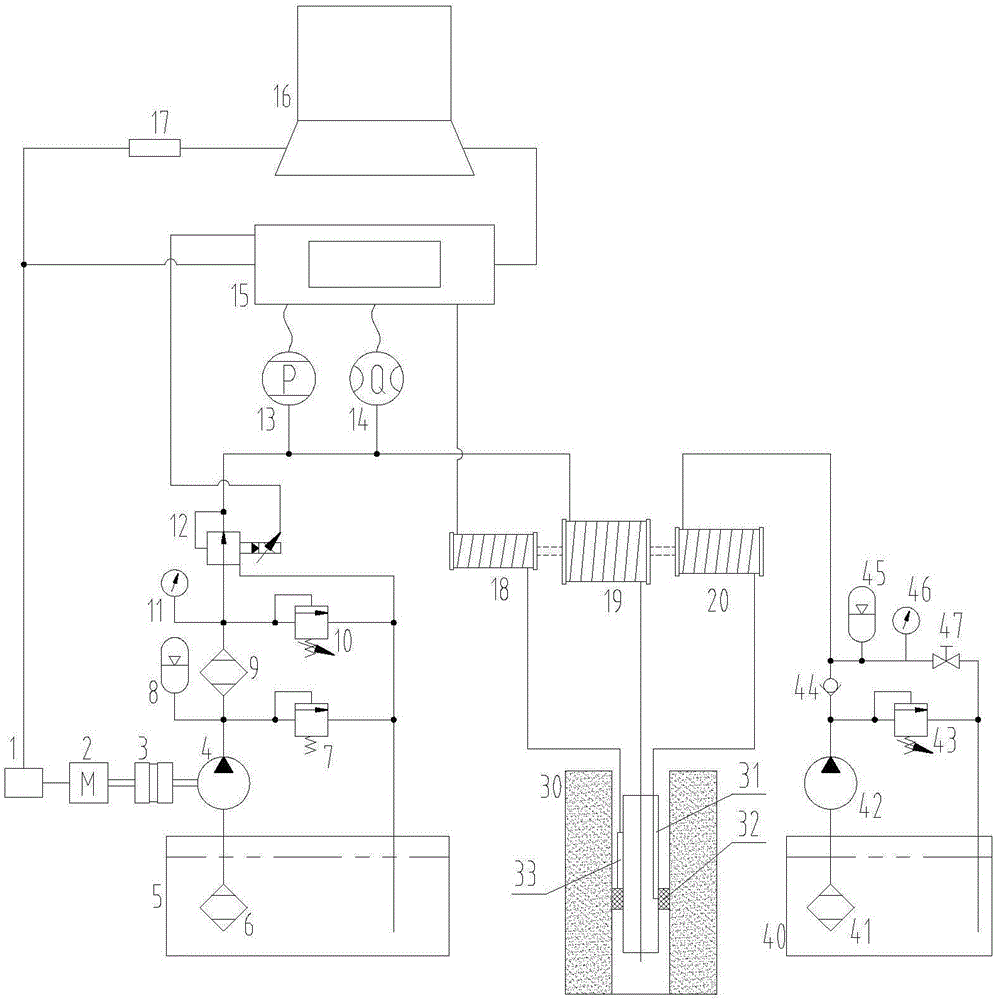

[0090] Refer to attached image 3 , Figure 9-Figure 11 , The difference between this embodiment and Embodiment 1 is that the electric proportional pressure regulating valve 12 adopts an electric proportional pressure reducing valve, and the rest are basically the same as Embodiment 1.

[0091] The high degree of intelligence improves the work efficiency, reduces the labor intensity of the operator, and improves the accuracy of the test results; the data accuracy is high; the output flow of the water pump is stable, and the pressure regulator tank and the electric proportional pressure regulating valve in the water supply system are in good condition. It has the function of voltage stabilization; light in weight; the software authority is classified and managed, and the test test data is supervised; it provides a complete set of solutions for the drilling water pressure test process, with high integration; the operation is simple and convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com