Test device and method for treating volatile and inflammable liquid through foam coverage

A flammable liquid and test device technology, applied in the direction of weighing by removing certain components, can solve the problems of complex experimental equipment and inability to achieve rapid evaluation, and achieve the effect of constant foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

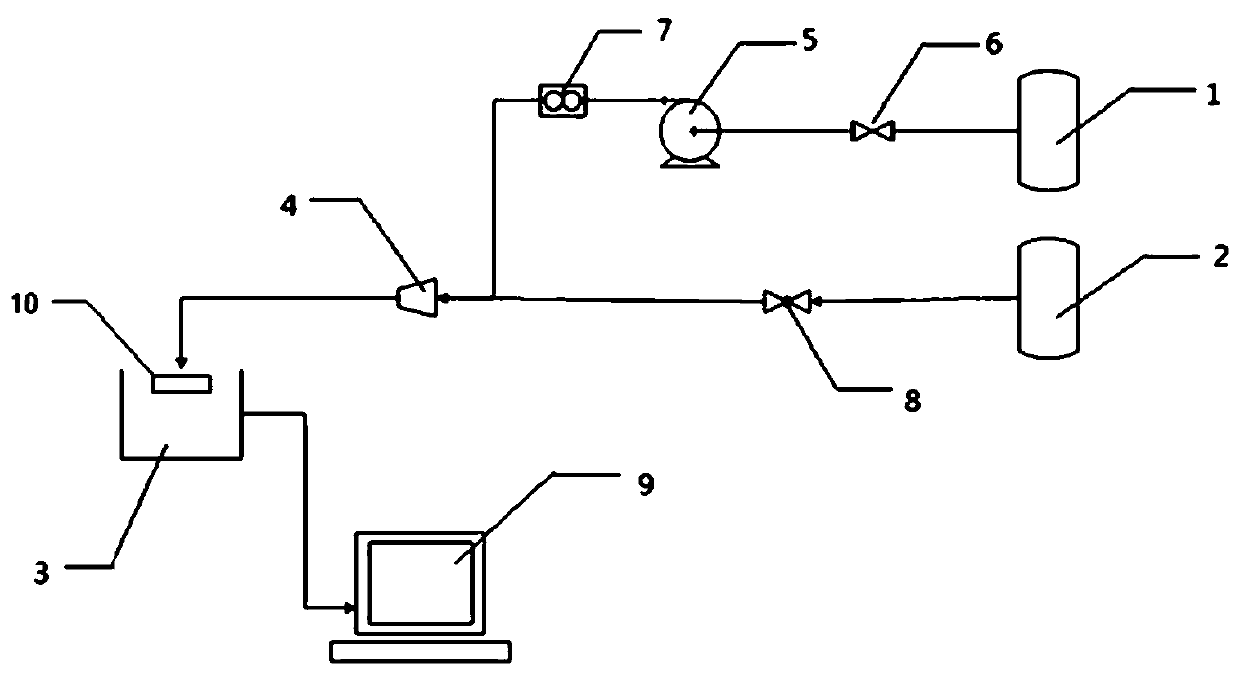

[0062] A test method for foam covering disposal of volatile and flammable liquids, the steps are as follows,

[0063] In the first step, put 20kg of fluoroprotein 3% anti-solubility water film-forming foam fire extinguishing agent A stock solution in the foam storage tank, which is a closed container, and install a valve with a flange at the outlet of the foam storage tank;

[0064] In the second step, add enough water to the 500L water storage tank, and the outlet of the water storage tank is connected to the one-way valve;

[0065] The third step is to open the one-way valve, start the delivery pump, water flows through the flow meter, adjust the water flow to 80L / min, the water supply pressure to 0.8MPa, and the foam expansion ratio to 6.5;

[0066] The fourth step is to open the valve, and the foam will flow through the valve in the form of negative pressure self-priming, and then mix and foam with water at the foam spray gun. During the process, ensure a certain flow rat...

Embodiment 2

[0074] In the first step, put 20kg of fluoroprotein 3% anti-solubility water film-forming foam fire extinguishing agent B stock solution in the foam storage tank, which is a closed container, and install a valve with a flange at the outlet of the foam storage tank;

[0075] In the second step, add enough water to the 500L water storage tank, and the outlet of the water storage tank is connected to the one-way valve;

[0076] The third step is to open the one-way valve, start the delivery pump, water flows through the flow meter, adjust the water flow to 70L / min, the water supply pressure to 0.8MPa, and the foam expansion ratio to 9.5;

[0077] The fourth step is to open the valve, and the foam will flow through the valve in the form of negative pressure self-priming, and then mix and foam with water at the foam spray gun. During the process, ensure a certain flow rate when the water flows through the foam spray gun, and ensure that the foam pipeline is in a certain negative pr...

Embodiment 3

[0085] A test method for foam covering disposal of volatile and flammable liquids, the steps are as follows,

[0086] In the first step, put 30 kg of fluoroprotein 3% anti-solubility water film-forming foam fire extinguishing agent A foam fire extinguishing agent stock solution into the foam storage tank, the foam storage tank is a closed container, and the outlet of the foam storage tank is installed with a valve with a flange;

[0087] In the second step, add enough water to the 500L water storage tank, and the outlet of the water storage tank is connected to the one-way valve;

[0088] The third step is to open the one-way valve, start the delivery pump, water flows through the flow meter, adjust the water flow to 150L / min, the water supply pressure to 0.7MPa, and the foam expansion ratio to 12;

[0089] The fourth step is to open the valve, and the foam will flow through the valve in the form of negative pressure self-priming, and then mix and foam with water at the foam s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com