Foaming product using air to replace foaming agent and preparation method thereof

A foaming agent and air technology, applied in the field of foaming products, can solve the problems of producing a large amount of foaming agent and peculiar smell, and achieve the effects of improving heat resistance, good dimensional stability and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

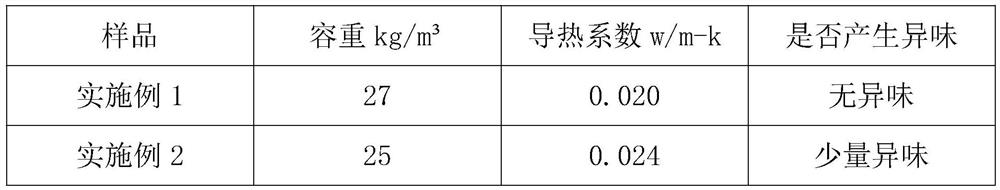

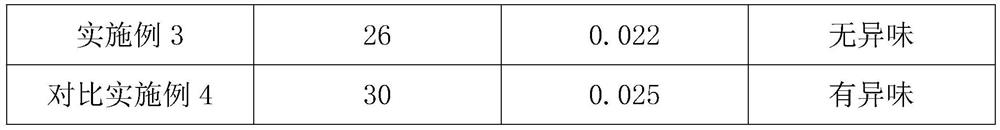

Examples

Embodiment 1

[0020] The invention provides a foaming product with air instead of a foaming agent and a preparation method thereof, which comprises the following raw materials in weight percentages of each component: 13% of soft styrene-butadiene rubber, 17% of natural rubber, 8% of terpolymer, o-phthalic acid Dioctyl dicarboxylate 17%, epoxy resin 25%, polyvinyl butyral 4%, azodicarbonamide 5%, high pressure low density polyethylene 10% and crosslinking agent 2%.

Embodiment approach

[0021] As a preferred embodiment of the present invention, the terpolymer consists of ethylene, propylene and non-conjugated diene.

[0022] As a preferred embodiment of the present invention, the epoxy resin is bisphenol A epoxy resin or epoxy-modified silicone resin.

[0023] As a preferred embodiment of the present invention, the preparation method comprises the following steps:

[0024] Step 1: Add soft styrene-butadiene rubber, natural rubber, terpolymer, dioctyl phthalate, epoxy resin, polyvinyl butyral and high-pressure low-density polyethylene into a closed rubber mixer for heating and mixing , the vested mixture;

[0025] Step 2: Add azodicarbonamide to the mixture obtained in step 1, and increase the heating temperature to mix again to obtain the initial mixture.

[0026] Step 3: Pour the raw material mixed in step 2 into the mold, add a crosslinking agent, and send it to a flat vulcanizer for crosslinking and foaming;

[0027] Step 4: Inject air into the mold in ...

Embodiment 2

[0033] The invention provides a foaming product with air instead of a foaming agent and a preparation method thereof, which comprises the following raw materials in weight percent of each component: 10% of soft styrene-butadiene rubber, 15% of natural rubber, 5% of terpolymer, o-phthalic acid Dioctyl dicarboxylate 15%, epoxy resin 20%, polyvinyl butyral 3%, azodicarbonamide 4%, high pressure low density polyethylene 5% and crosslinking agent 1%.

[0034] As a preferred embodiment of the present invention, the terpolymer consists of ethylene, propylene and non-conjugated diene.

[0035] As a preferred embodiment of the present invention, the epoxy resin is bisphenol A epoxy resin or epoxy-modified silicone resin.

[0036] As a preferred embodiment of the present invention, the preparation method comprises the following steps:

[0037] Step 1: Add soft styrene-butadiene rubber, natural rubber, terpolymer, dioctyl phthalate, epoxy resin, polyvinyl butyral and high-pressure low-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com