A kind of novel tpu sole and preparation method thereof

A novel, step-by-step technology, applied to shoe soles, footwear, footwear, etc., can solve the problems of high price, limited application scope, etc., and achieve the effect of firm sole and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

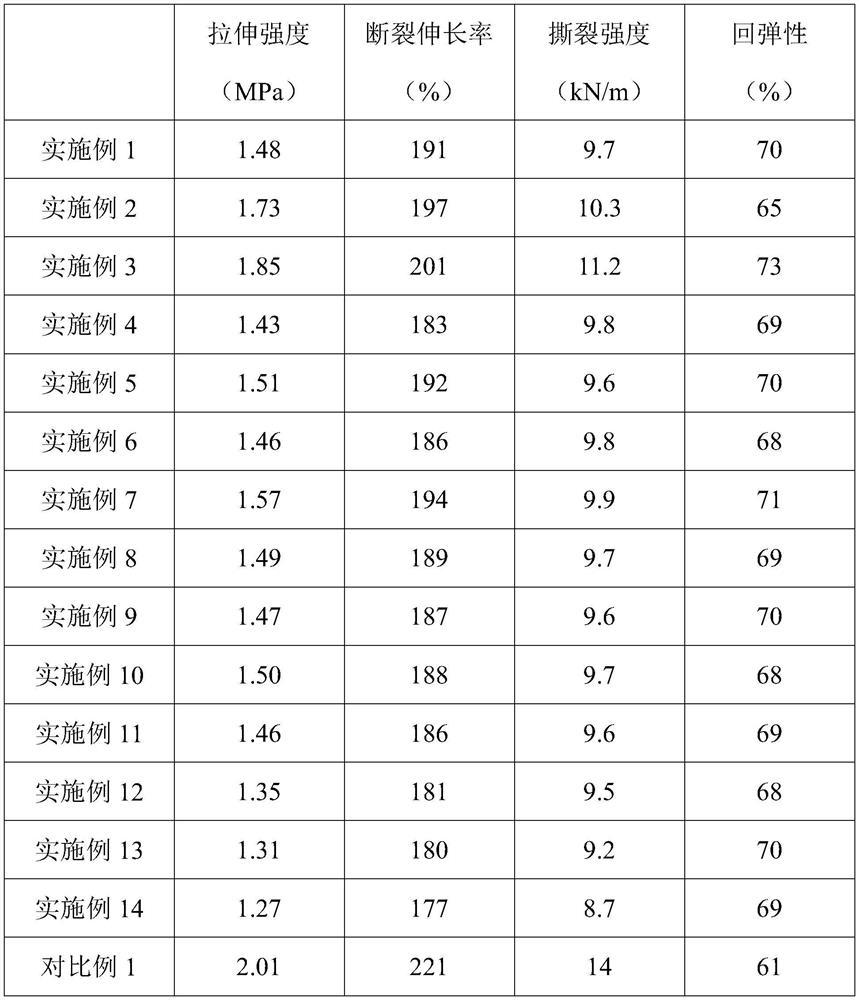

Examples

preparation example 1

[0046] The elastic filler solid of Preparation Example 1, its preparation steps are as follows:

[0047] After the waste leather is washed and dried, it is sterilized at 90° C. and then crushed. The average crushed particle size is 0.3 cm to obtain a solid elastic filler.

preparation example 2

[0049] The elastic filler solid of Preparation Example 2, its preparation steps are as follows:

[0050] After the EVA waste is washed and dried, it is sterilized at 95° C. and then crushed. The average crushed particle size is 0.8 cm to obtain a solid elastic filler.

preparation example 3

[0052] The elastic filler solid of Preparation Example 3, its preparation steps are as follows:

[0053] After washing and drying the waste of shoes and clothing, it is sterilized at 100° C. and then crushed. The crushed particle size is 1.2 cm on average to obtain a solid elastic filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com