Multi-cavity shaft system particle damper

A particle damper and multi-cavity shaft technology, applied in the direction of friction shock absorber, etc., can solve the problems of system dynamic imbalance and achieve the effects of reduced dynamic imbalance, low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

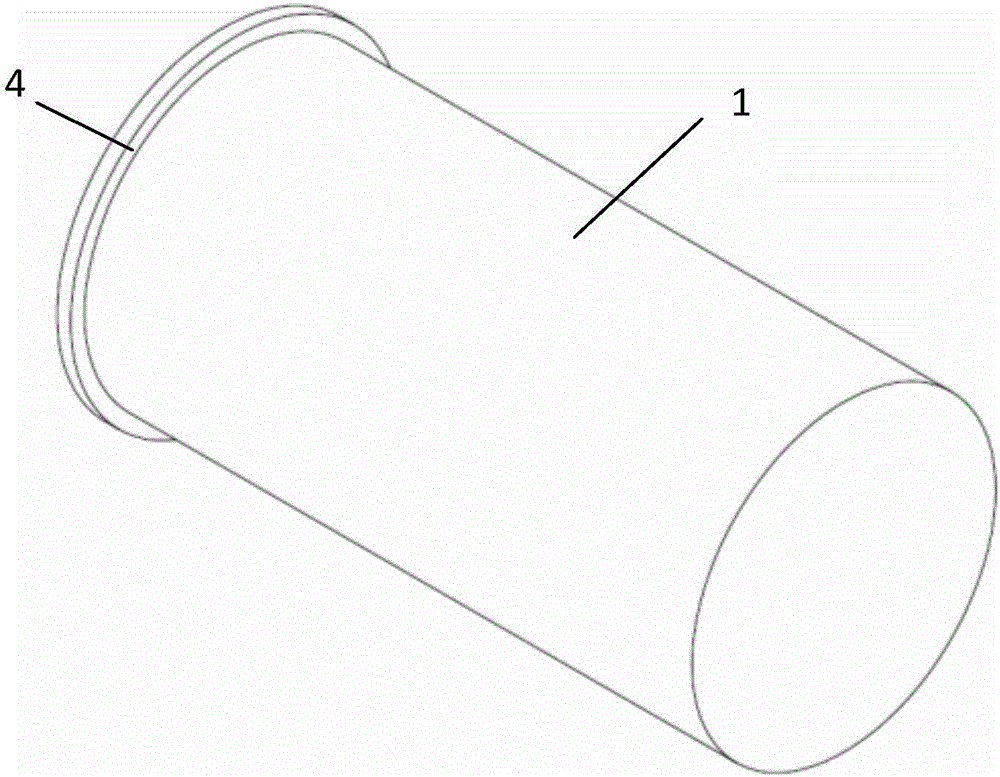

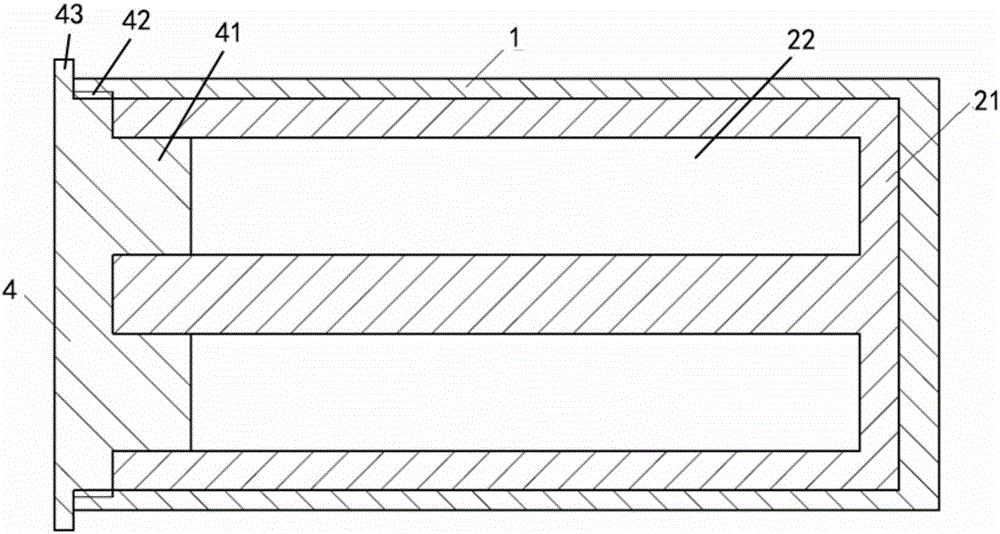

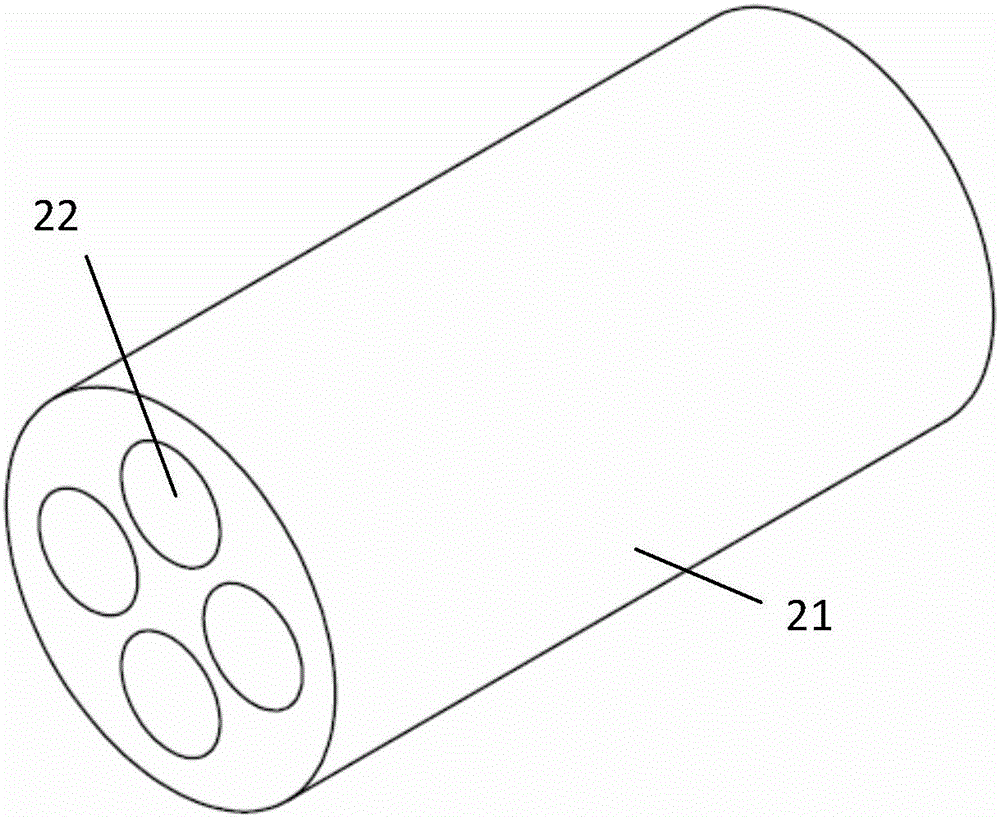

[0035] Figure 1-8 A schematic diagram of the assembly. The embodiment of the present invention is provided with a cylinder 21, and four axial cavities 22 are arranged in the cylinder 21. The opening end of the axial cavities 22 is provided with a fixed cover plate 4, and particles are filled in the axial cavities 22. 3.

[0036] The front end of the fixed cover plate 4 is provided with an end cover 43, the rear end of the fixed cover plate 4 is provided with a shaft 41 matched with the axial cavity 22, and a connecting portion 42 is provided between the end cover 43 and the shaft 41, The connecting portion 42 is provided with external threads.

[0037] The material, particle size and number of particles filled in each axial cavity are the same.

[0038] The axial cavity can be divided into 4-6 sections in the axial direction.

[0039] When the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com