A low-noise control valve with pre-start structure

A low-noise, regulating valve technology, applied in the field of regulating valves, can solve problems such as large noise, achieve the effects of reducing fluid noise, improving flow capacity, and reducing initial lifting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

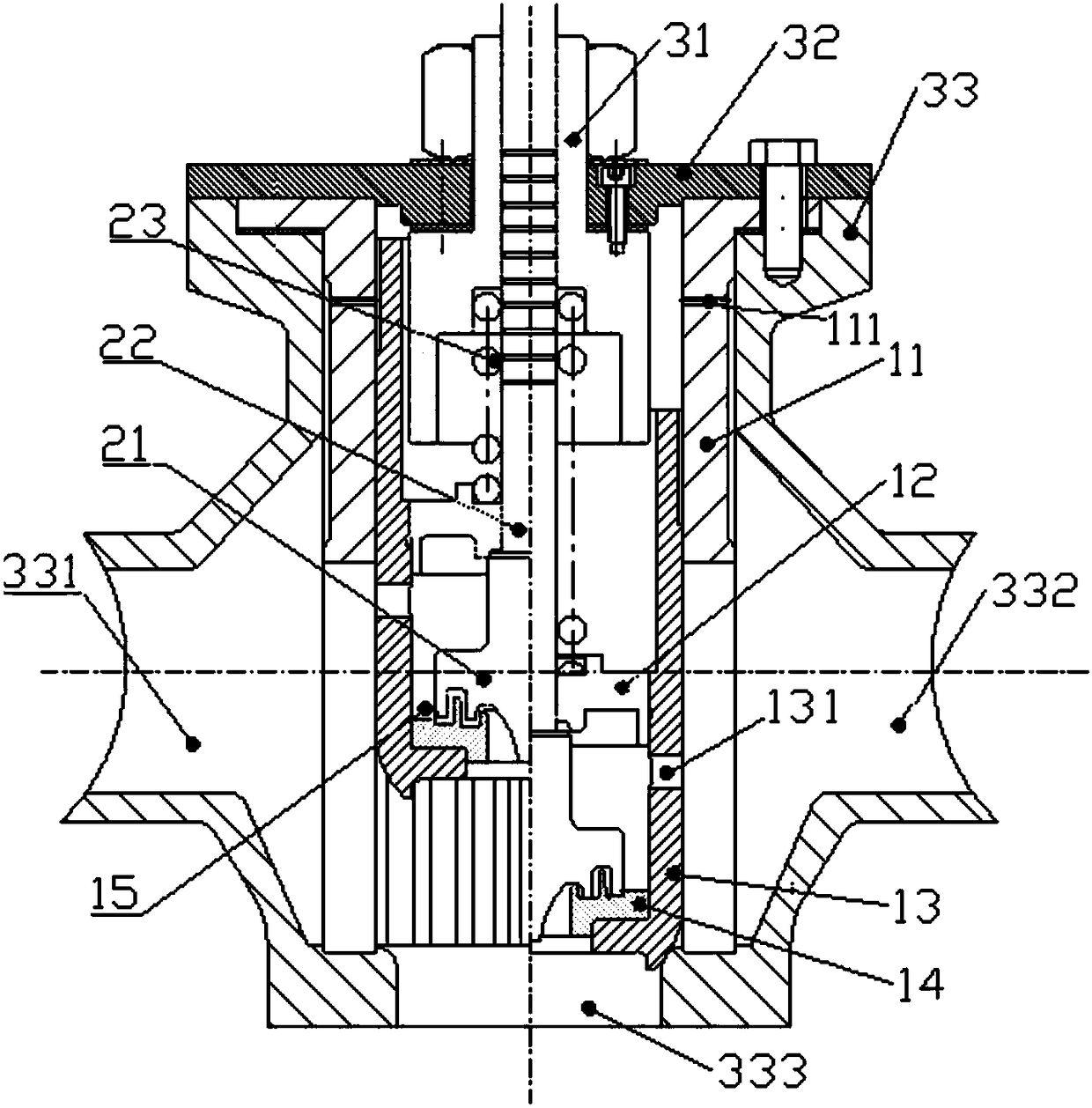

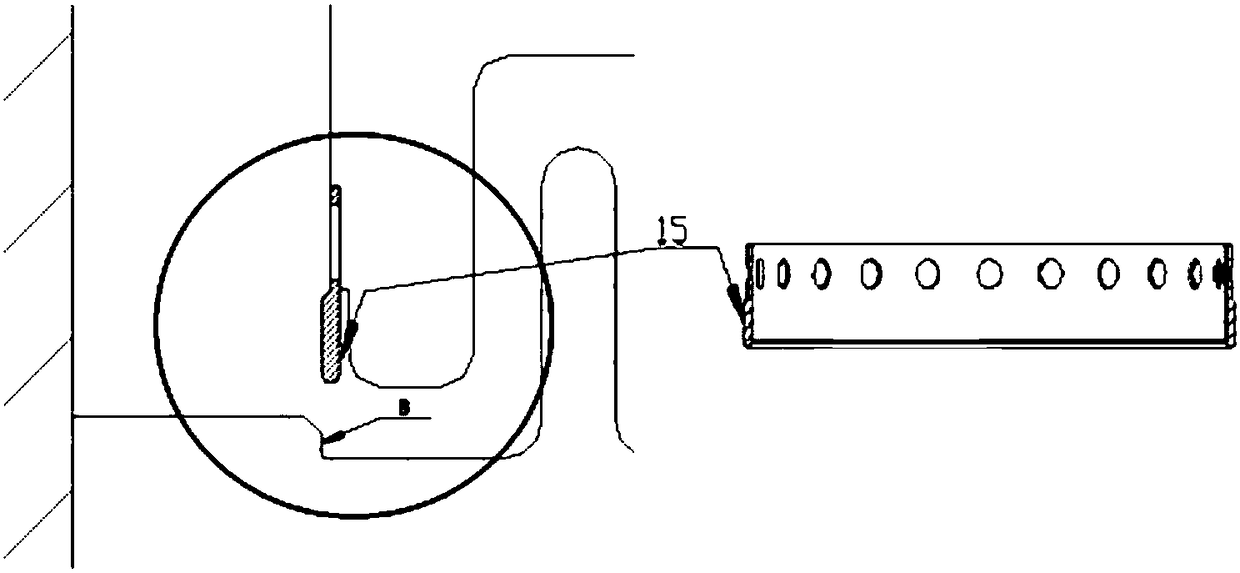

[0017] Example 1: Combining Figure 1 to Figure 5 , the present invention includes a three-way valve body 33, a valve stem 22, a pre-opening plunger 21, a large flow throttling element 11, a baffle plate 12, a valve head 13, a pre-opening valve seat 14, a sealing spring ring 15, a compression spring 23, Pressing member 31, upper cover plate 32, etc., the lower end of the three-way valve body is provided with an outflow channel, and both sides are symmetrically provided with inflow channels, that is, the valve body 33 of the present invention has inflow channels 331, 332 and outflow channels 333 , the middle of the valve body is provided with a valve chamber in a three-way shape, two inflow passages are symmetrically arranged on the left and right sides, and an outflow passage is arranged at the lower end. The inflow passage and the outflow passage pass through the valve chamber. and the pre-opening structure are coaxially fitted and form a sealing fit with the opening end of t...

Embodiment 2

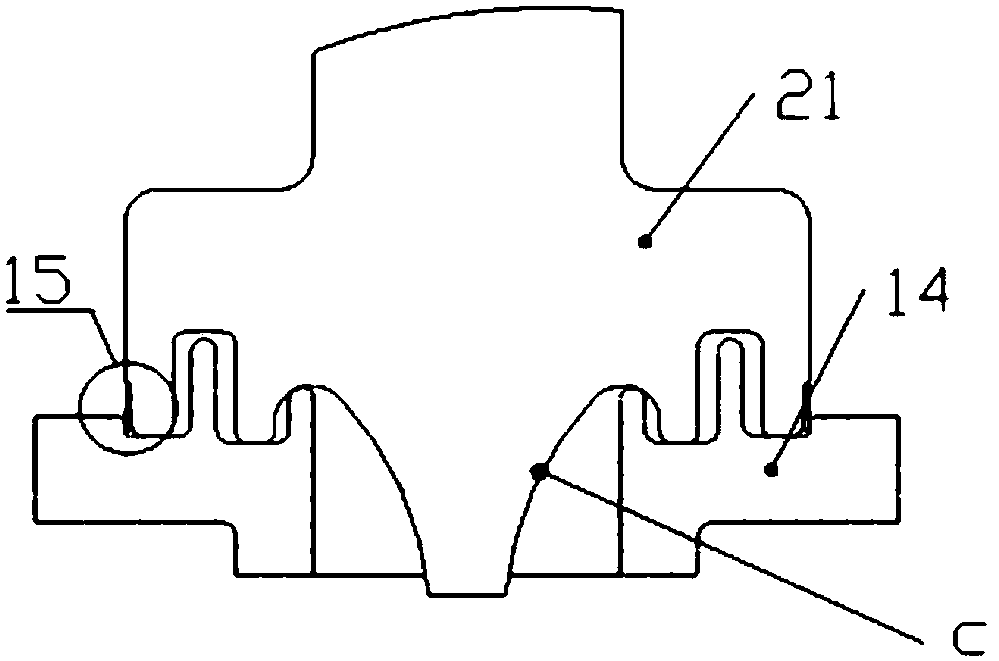

[0029] Embodiment 2: Based on the above-mentioned embodiment, the present invention can also be: the center position of the bottom of the pre-opening plunger is provided with a curved rotary body that slows down the vortex collision downstream of the pre-opening valve seat, forming a vortex separation structure, and the lower end is connected to the pre-opening valve seat. The opening of the valve outflow channel is in the same horizontal plane, such as figure 2 shown. After the fluid flows through the pre-opening labyrinth throttling channel, the curved guide structure at the center of the pre-opening plunger can realize the rectification effect on the post-opening valve, avoiding the turbulent hedging of the fluid behind the valve. After the fluid flows out of the pre-opening valve seat, due to the existence of the curved body C at the center of the pre-opening plunger, it can play a group role in slowing down the eddy current collision downstream of the pre-opening valve s...

Embodiment 3

[0030] Embodiment 3: Based on the above embodiment, the present invention can also be: the middle and upper part of the large-flow throttling element is provided with an annular groove, and the annular groove is provided with a plurality of openings to realize penetration. The large-flow throttling element is arranged outside the valve head, and a number of through open flow areas are opened on the large-flow throttling element, and the valve head can slide axially on the inner surface of the large-flow throttling element. The shape, size and quantity of the runners can be calculated and determined according to the actual working conditions. The fluid passes through the large flow throttling element and the through slit on the valve head to realize the communication between the external valve cavity and the pre-opening valve cavity.

[0031] The working process of the present invention is: when the valve is opened, the pre-opening plunger 21 is first lifted, and the fluid pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com