Three-layer co-extrusion sandwiched honeycomb pipe and production technology thereof

A three-layer co-extrusion and production process technology, applied in the field of plastic pipes, can solve the problems of low environmental stress cracking resistance, high production equipment costs, and low radial ring stiffness, achieving high radial ring stiffness and light overall weight , the effect of high axial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

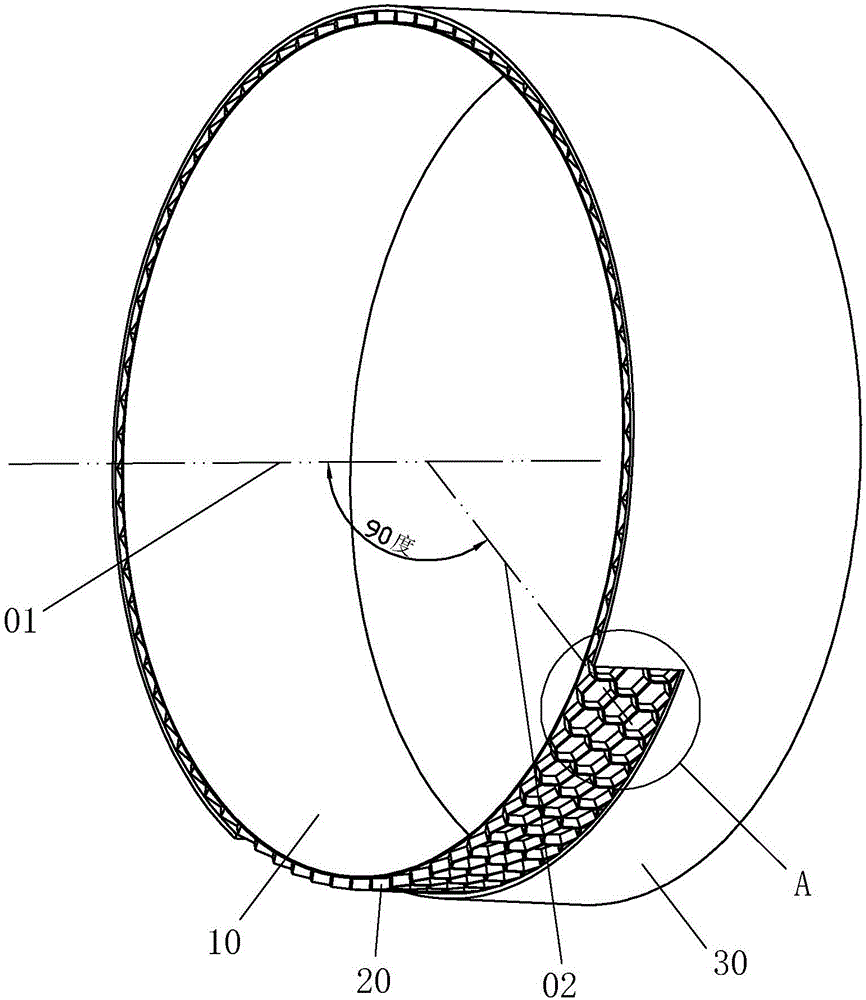

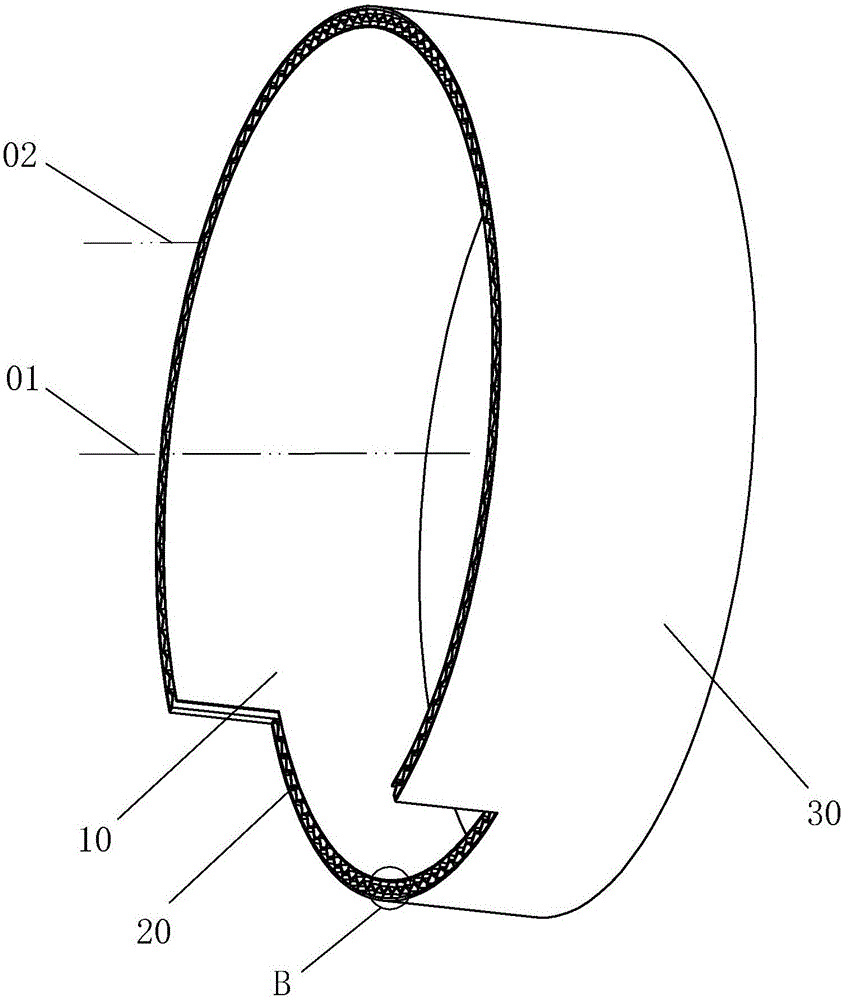

[0019] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-Figure 4 :

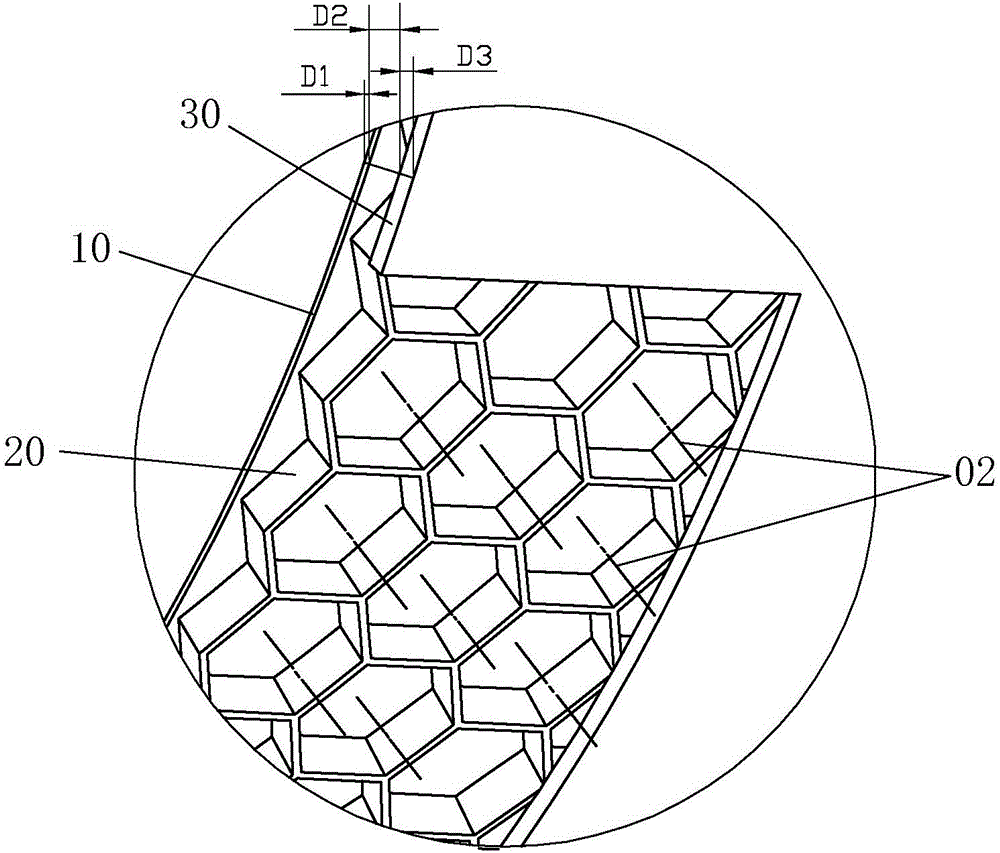

[0020] Three-layer co-extruded sandwich honeycomb tube, comprising an inner tube 10, an outer tube 30 and a sandwich layer 20 between the inner tube 10 and the outer tube 30, the inner tube 10, the sandwich layer 20, the outer layer The tube 30 is an integral structure made of plastic material extruded at one time, the tube walls of the inner tube 10 and the outer tube 30 are solid structures, and the sandwich layer 20 is a honeycomb structure layer.

[0021] The axis 02 of the honeycombs of the above-mentioned honeycomb structure layer is perpendicular or parallel to the axis 01 of the inner tube 10 or / and the outer tube 30 .

[0022] The thickness ratio of the inner layer tube 10 , the sandwich layer 20 , and the outer layer tube 30 is 1:(5-8):(2-4).

[0023] The production process of the three-layer co-extruded sandwic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com