A flue gas waste heat recovery device

A recovery device and flue gas waste heat technology, applied in preheating, liquid degassing, indirect heat exchangers, etc., can solve the waste of flue gas waste heat resources, etc., to improve waste heat recovery efficiency, promote coordinated development, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

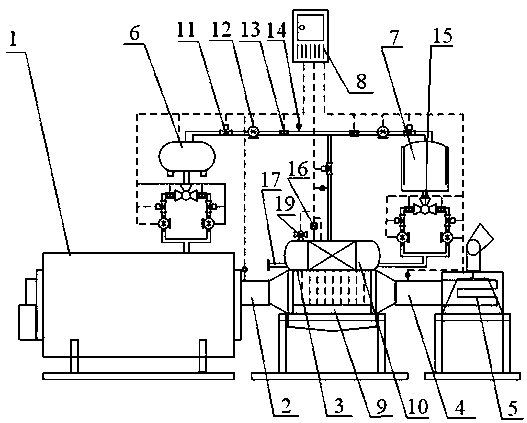

[0016] Embodiment 1: as figure 1 As shown, a flue gas waste heat recovery device includes a gas boiler 1, a high-temperature flue gas exhaust pipe 2, a flue gas heat exchanger 3, a softened water storage device 7, a low-temperature flue gas pipe 4, a low-temperature flue gas desulfurization discharge device 5, Hot water deaerator 6 and automatic control cabinet 8, the gas boiler 1 is connected to the high-temperature flue gas inlet of the flue gas heat exchanger 3 through the high-temperature flue gas exhaust pipe 2, and the low-temperature flue gas outlet of the flue gas heat exchanger 3 passes through The low-temperature flue gas pipeline 4 is connected to the low-temperature flue gas desulfurization discharge device 5, the water supply port of the flue gas heat exchanger 3 is connected to the softened water storage device 7 through the water supply pipe network, and the water outlet of the flue gas heat exchanger 3 is connected to the water supply port through the water supp...

Embodiment 2

[0017] Embodiment 2: as figure 1 As shown, as an improvement of the present invention, the finned superconducting heat pipe is made of polytetrafluoroethylene. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0018] Embodiment 3: as figure 1 As shown, as an improvement of the present invention, an induced draft fan is provided between the low-temperature flue gas desulfurization discharge device 5 and the low-temperature flue gas pipeline 4, and the air inlet of the induced draft fan is connected to the low-temperature flue gas pipeline 4. The air outlet is connected to the low-temperature flue gas desulfurization discharge device 5 . The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com