Receiver-drier with heat regeneration function and reversing function

A liquid storage dryer and dryer technology, applied in refrigeration and liquefaction, lighting and heating equipment, refrigeration components, etc., can solve the problems of unfavorable engine room layout, occupying engine room space, high cost, and avoiding occupying engine room space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

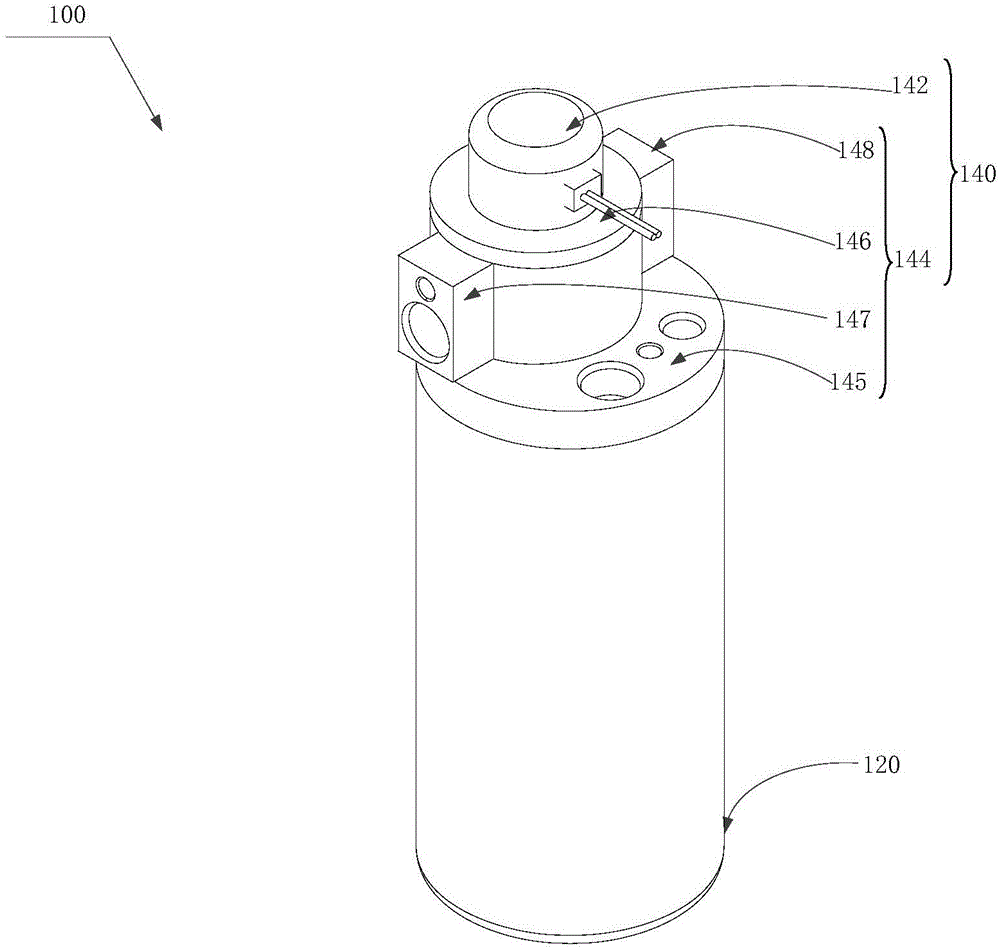

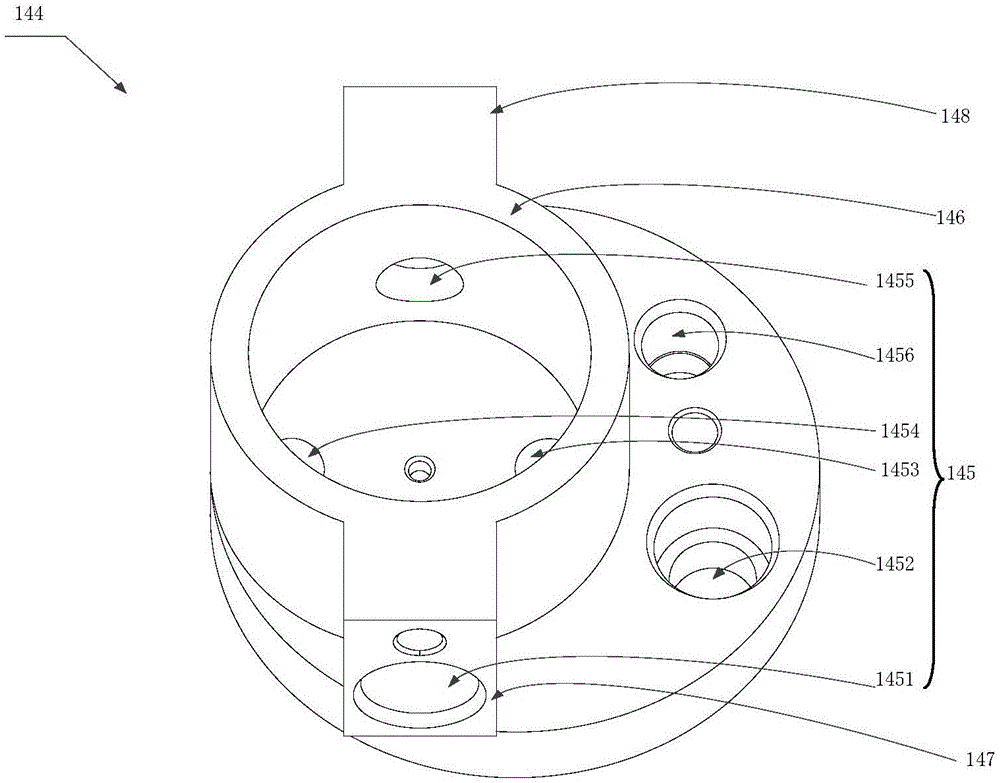

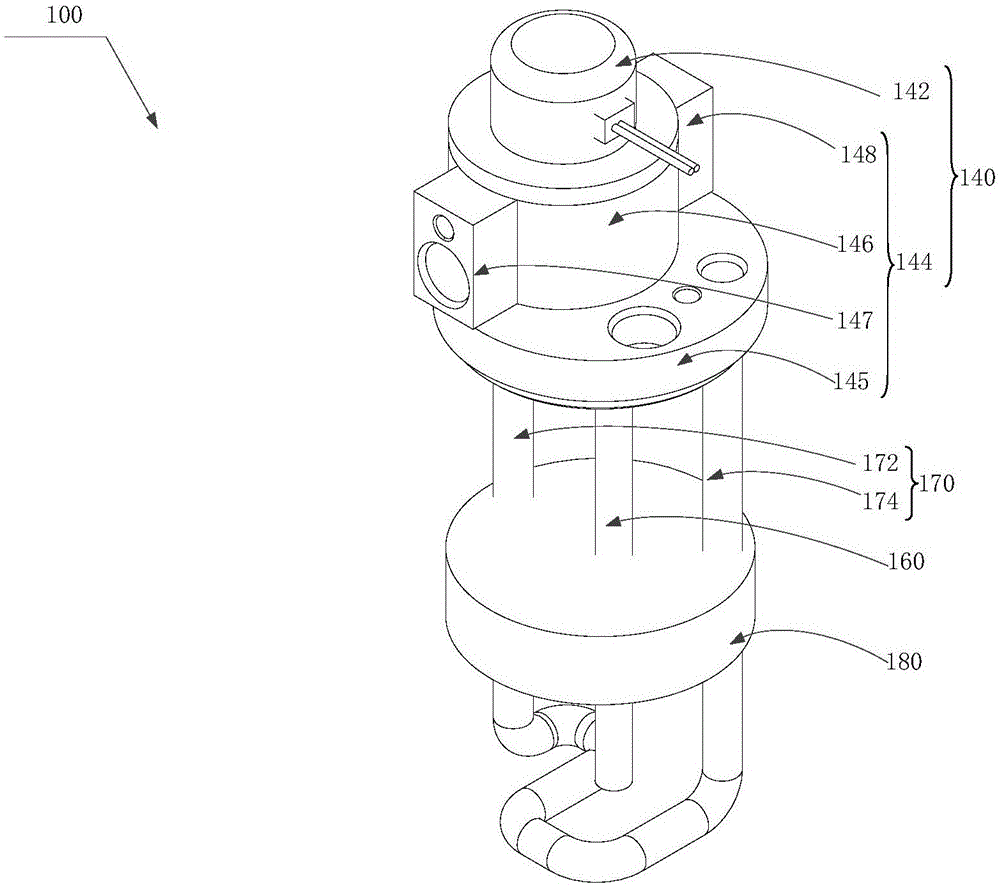

[0037] Please refer to Figure 1 to Figure 4 , shows a schematic structural view of a liquid storage drier 100 with heat recovery function and reversing function provided by this embodiment. The dryer 100 includes a tank body 120, an automatic reversing device 140, a drainage tube 160 and an internal communication tube 170, the drainage tube 160 and the internal communication tube 170 are both arranged in the tank body 120, and the automatic The reversing device 140 is disposed at the open end of the pipe body, and both the drainage tube 160 and the internal passage tube 170 are in communication with the automatic reversing device 140 .

[0038] See figure 1 and Figure 4 , the tank body 120 is a tubular structure with one end open, and the tank body 120 is provided with an accommodating chamber and an open end. The tank body 120 is preferably made of heat-insulating, moisture-proof, and corrosion-resistant materials.

[0039] See image 3 , the drainage tube 160 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com